CONDITION MONITORING SYSTEM

Condition Monitoring for Reliable Plants

Stay ahead of downtime and catch failures before they cost you with real-time Condition Monitoring.

Condition Monitoring for Reliable Plants

Stay ahead of downtime and catch failures before they cost you with real-time Condition Monitoring.

HOW OUR FAILURE DETECTION WORKS

Sample & Detect

Sensors stream real-time vibration, temperature, runtime, and RPM. AI maps the signal patterns to specific failure modes (e.g., bearing wear, misalignment, unbalance).

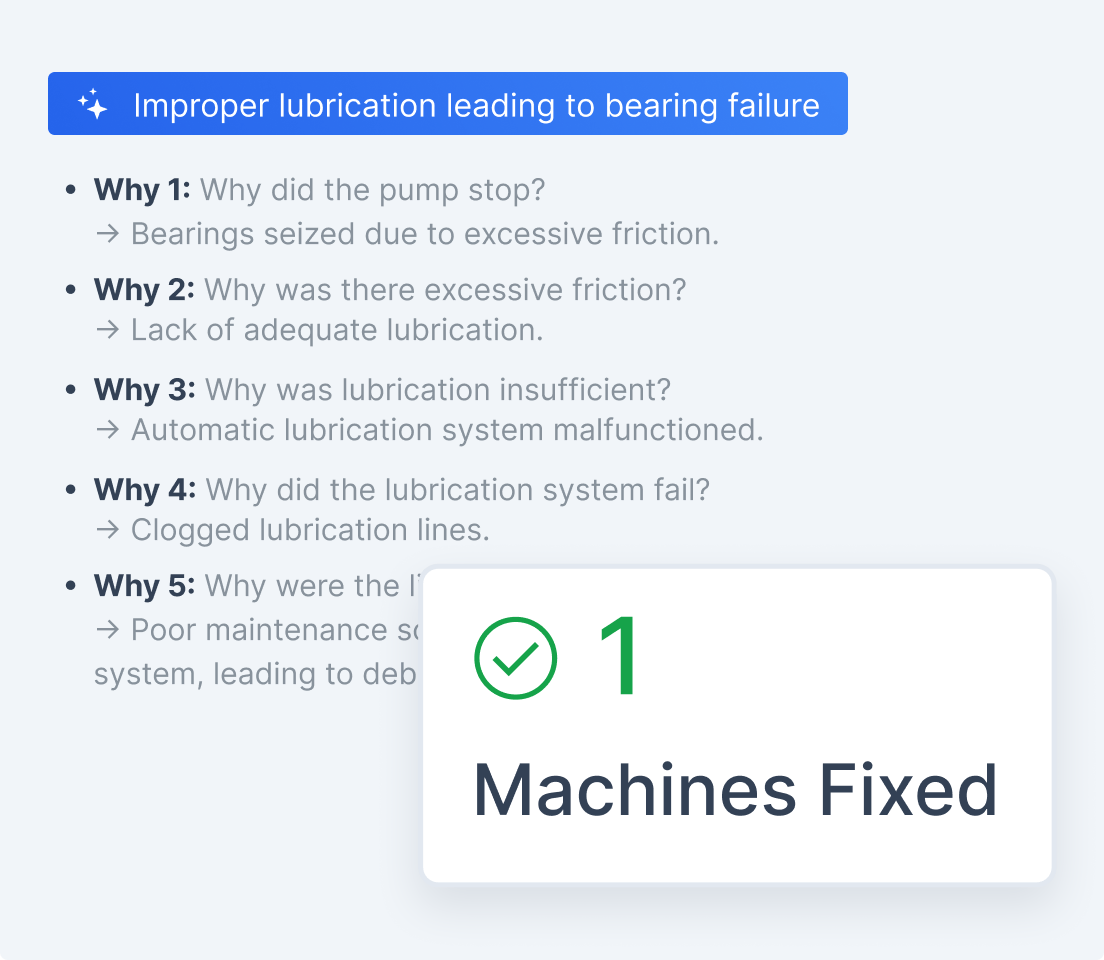

Diagnose with Context

Your data is benchmarked against millions of historical machine hours and bearing libraries to make an accurate, explainable call, complete with evidence.

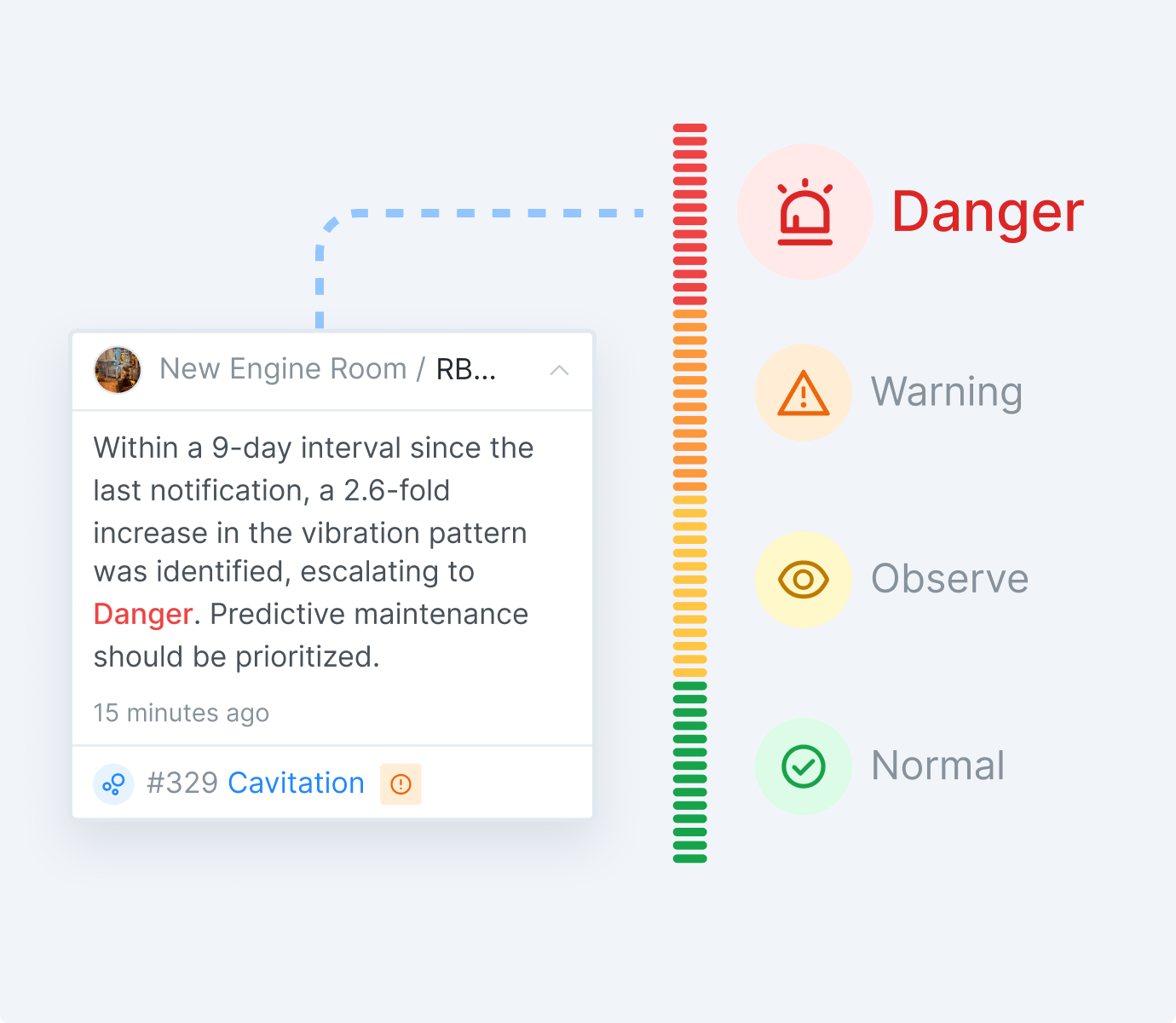

Prioritize What Matters

Alerts are ranked by failure severity and asset criticality, so mission-critical machines rise to the top while low-impact noise stays out of the way.

Notify & Act

You get an alert that spells out the root cause and next steps. The only thing left to do is the fix.

Axial Fans

Bearings

Centrifugal Compressors

Centrifugal Fans

Centrifugal Pumps

Centrifugal Chillers

Chillers

CNCs

Compressors

Conveyors

Cooling Towers

Dryers

Electric Motors

Exhaust Fans

Extruders

Fans

Filters

Gearboxes

Generators

HVACs

Hydraulic Pumps

Industrial Sleeves

Injection Molding Machines

Mills

Mixers

Mold Blowers

Overhead Cranes

Presses

Screw Chillers

Screw Compressors

Spindles

Servo Motors

Sanders

Screw Pumps

Shaft Trees

Turbines

Vacuum Pumps

Winders

Axial Fans

Bearings

Centrifugal Compressors

Centrifugal Fans

HVACs

Hydraulic Pumps

Industrial Sleeves

Injection Molding Machines

Bearing Erosion

Bearing Wear

Belt Wear

Blade Passage

BPFO

BPFI

Cavitation

Damage Rotor Bars

Friction

Gear Eccentricity

Gear Wear

Inner Bearing Wear

Loose Rotor Bars

Lubrication Failures

Loose Stator Windings

Misalignment

Outer Bearing Wear

Overheating

Overvoltage

Overload

Operational Problems

Phase Unbalance

Pipe Deformation

Pulley Wear

Pump Recirculation

Resonance

Rotating Looseness

Rotor Eccentricity

Rotor Meshing

Structural Mechanical Looseness

Shaft Eccentricity

Stator Eccentricity

Turbulence

Unbalance

Vane Passage

Bearing Erosion

Bearing Wear

Belt Wear

Blade Passage

Overvoltage

Overload

Operational Problems

Phase Unbalance

MILLS & AGRICULTURE

“There were some issues that I would say, if not for having Tractian, we would have never noticed… For example, a lubrication problem, we could go out and lubricate it and recheck it on Tractian platform and see that it fixed the problem… It was pretty impressive for that, the results we got early on.”

Jacob Hoffine

Reliability Engineer

From first sample to fixed machine - detect, diagnose, act, and prove value in one platform.

From first sample to fixed machine - detect, diagnose, act, and prove value in one platform.

BEST-IN-CLASS HARDWARE. out of the box.

Battery Life

3–5 years

Sampling

Vibration, Trends, and Spectrum up to 32kHz, Temperature, RPM, and Sound

Connectivity

4G/LTE, up to 330 ft with obstacles, 3,300 ft Line of Sight

Temperature Range

-40°F to 250°F

Certified for Hazardous Locations

Class 1 Div 1 (ATEX, IECEx, NFPA compliant)

IP69K Rated

Fully sealed & resistant to water and dust particles

Chat with one of our experts for a quick walkthrough of the platform.

FAQ

Need something specific we didn’t cover? Our sales team is ready to help at +1 (833) GET-TRAC