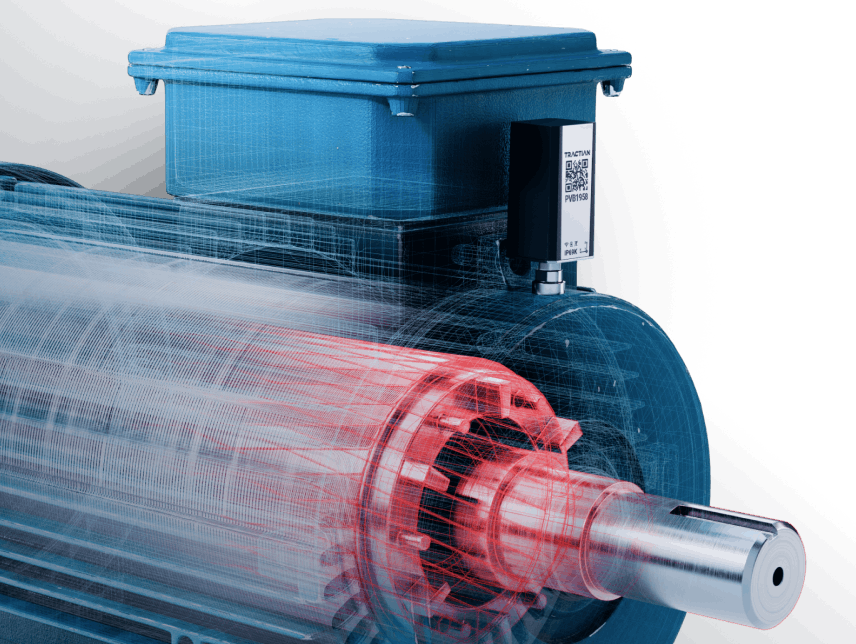

Industrial

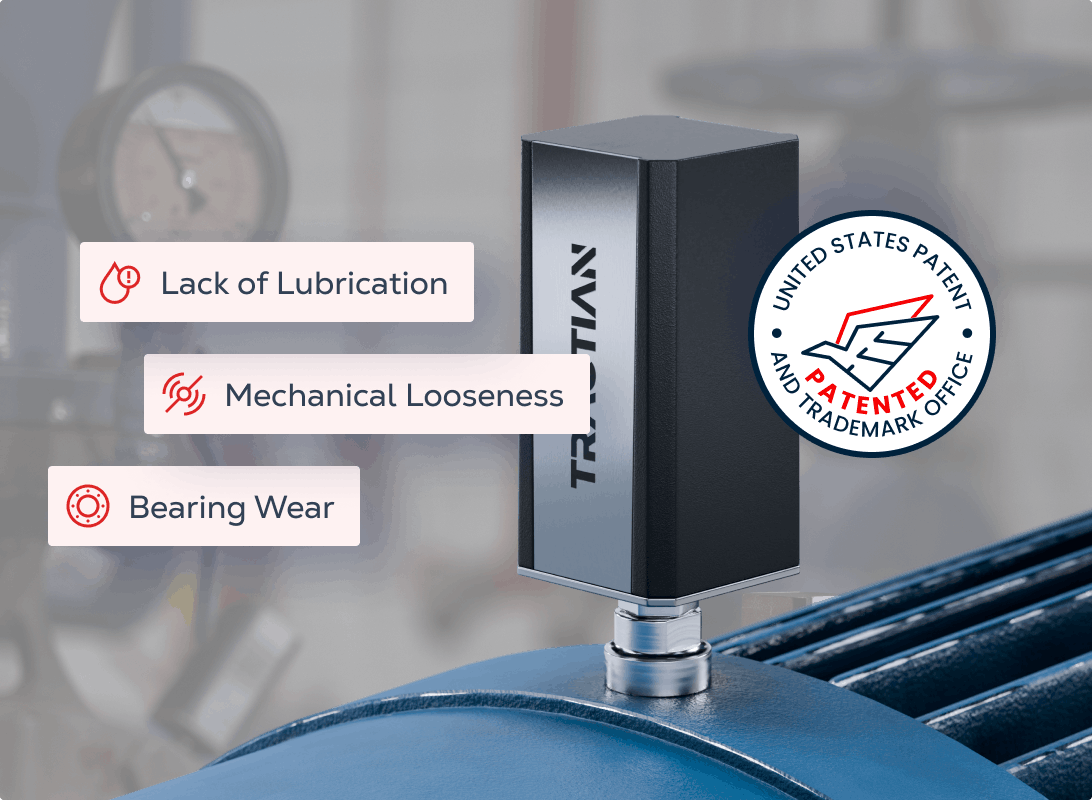

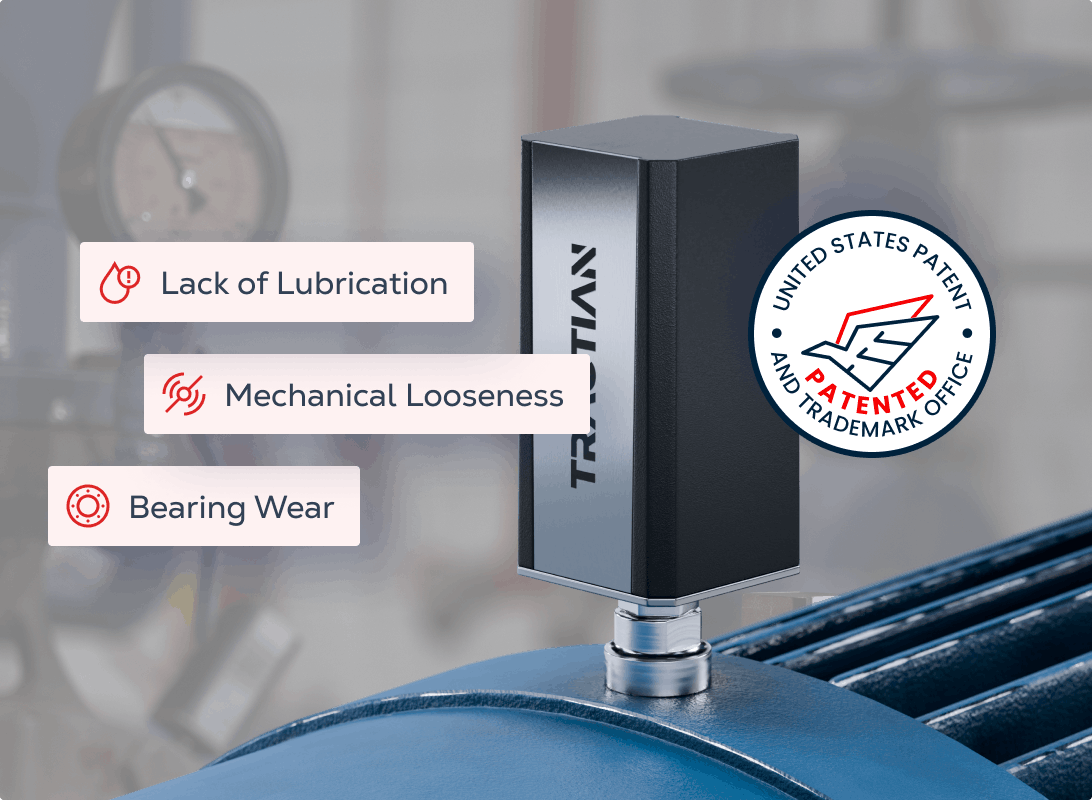

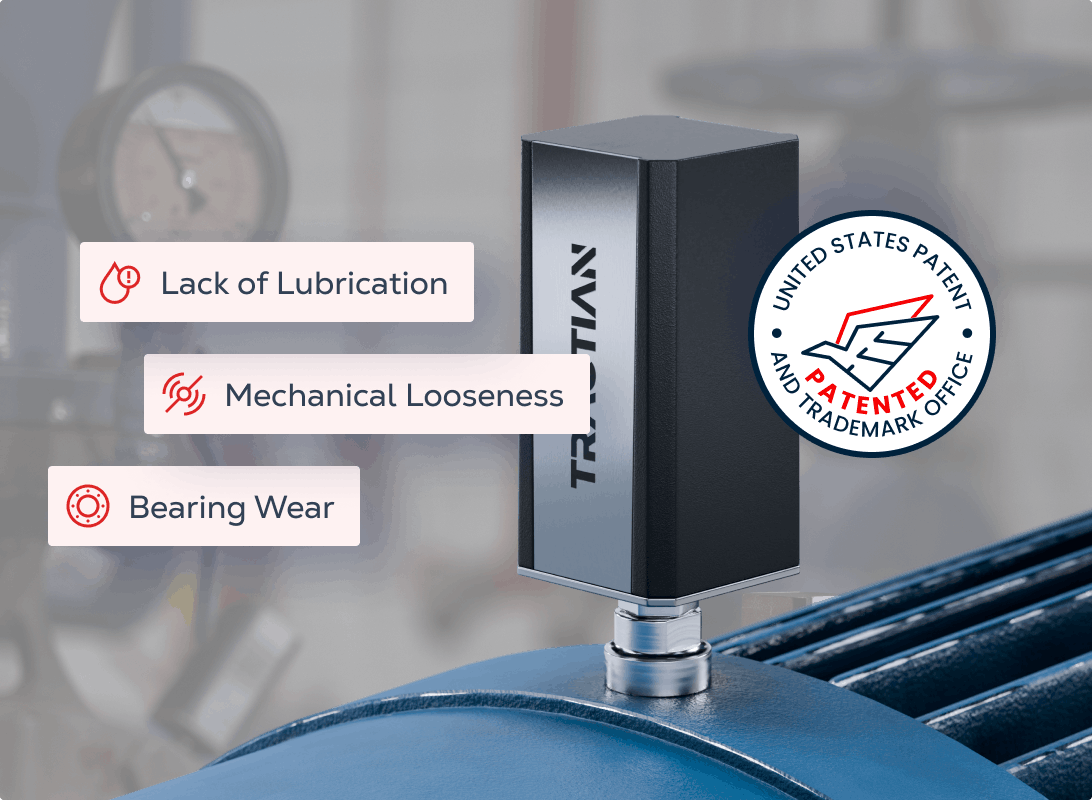

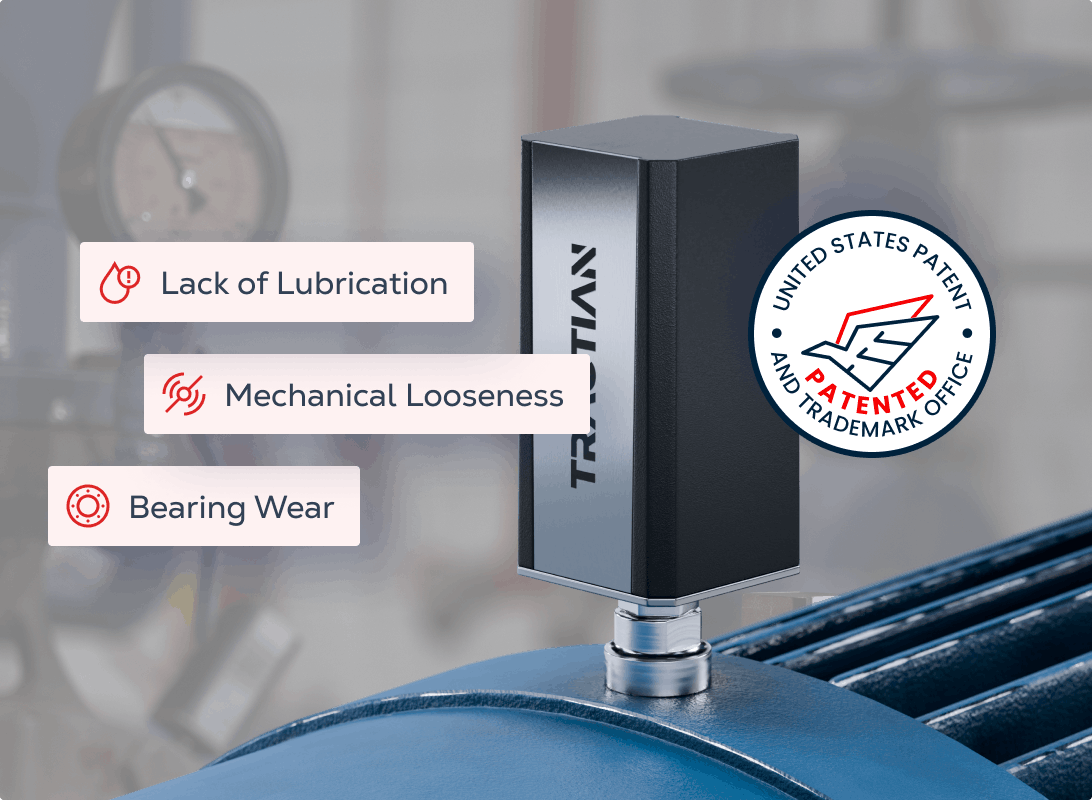

Vibration Sensor

Industrial

Vibration Sensor

Accurately monitor the condition of your industrial equipment in real time. Avoid unexpected failures, reduce costs and increase operational efficiency.

Accurately monitor the condition of your industrial equipment in real time. Avoid unexpected failures, reduce costs and increase operational efficiency.

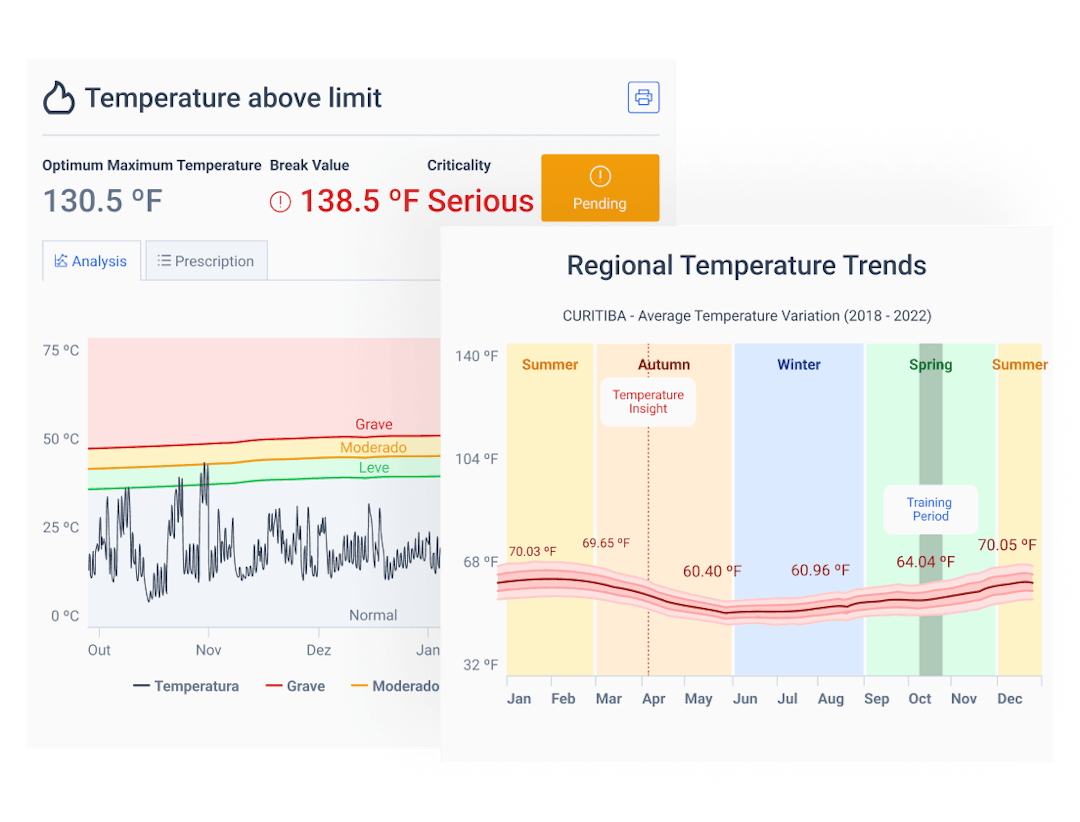

Fault Detected

The sensor detects a failure based on vibration, temperature, and runtime data collected in real time.

The constant collection of information disregards temperature oscillations from one season to another, eliminating errors and allowing accurate fault detection, considering only the temperature of the analyzed asset.

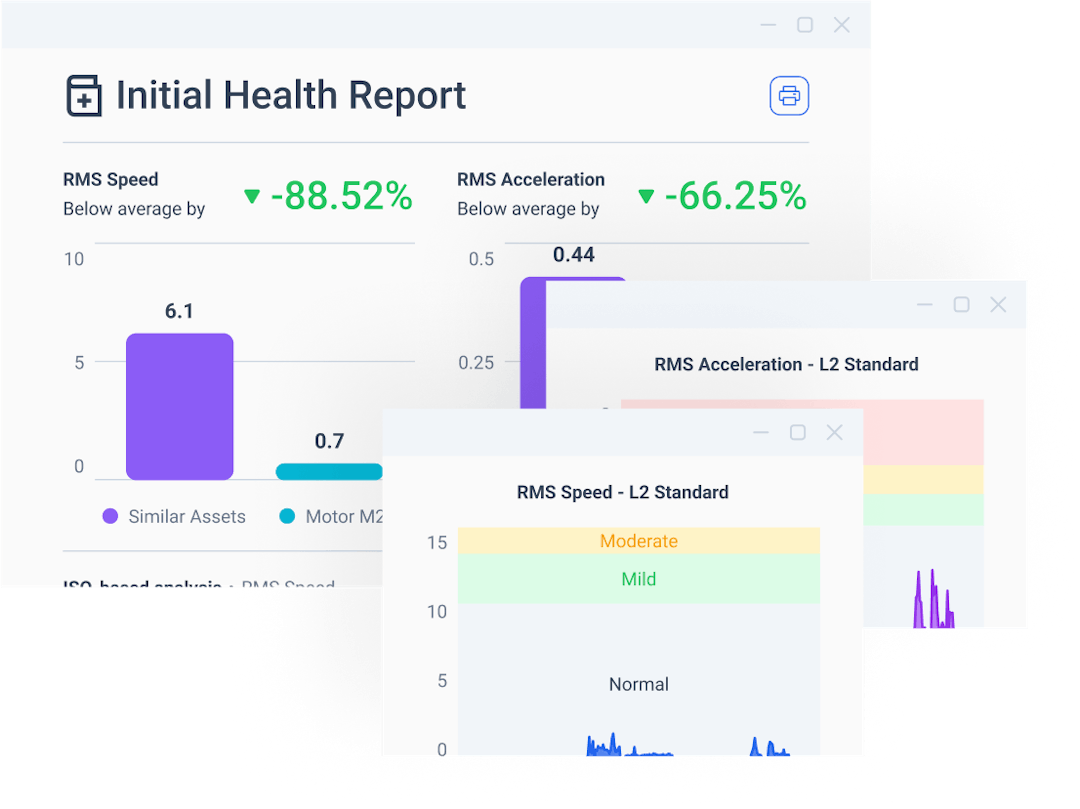

The state of health of the asset through vibration, precisely, up to 5 days after installation, enhancing the reading of the machine's behavior and its ideal functioning in the industry, identifying failures from the first days of installation.

Companies that have critical industrial equipment that needs constant monitoring

Professionals/Industries seeking to increase operational efficiency, reduce maintenance costs, and avoid unscheduled downtime

Managers, Supervisors, Directors, Operators, Technicians, and Planners who need to work with real-time data

FEATURE

Patented failure diagnosis algorithms

Full vibration spectrum analysis

Cloud-based information storage software

Historical analysis records and asset trend tracking

Utilizes local weather data for temperature trend analysis

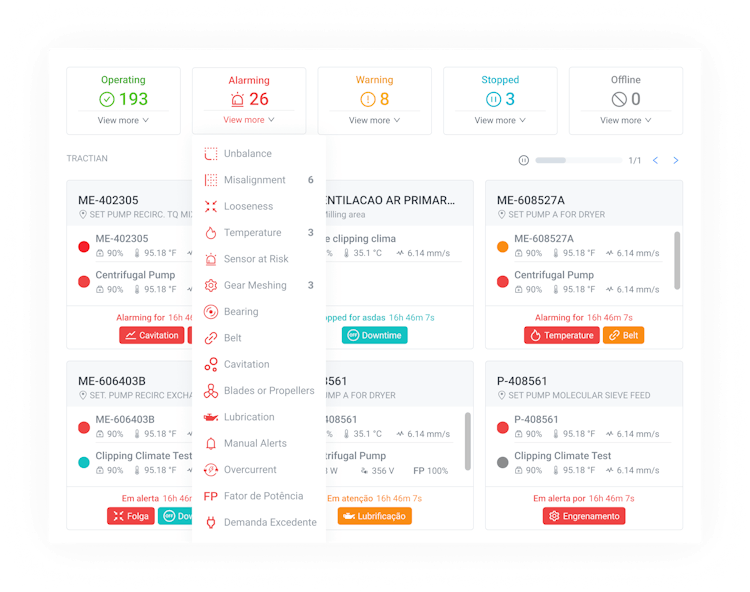

Real-time, condition-based maintenance

Machine inspection suggestions based on manufacturer manuals

Automatic work order creation and scheduling

Detection and diagnosis of both mechanical and electrical failures

Ensuring employee safety with remote data sampling during machine operation

Performance analysis of your machine compared to your competitors

Monitor and analyze the vibration and temperature of your equipment in real time

Identify potential failures before they occur

Receive immediate alerts in case of deviations or anomalies

Schedule preventive maintenance based on reliable data

Increase the life of your equipment and reduce maintenance costs

IP69K resistance against steam and high-pressure water jets

Lined with Makrolon 2407 with thermal insulation

Temperature sensor as close as possible to asset without being invasive

M8 base that supports vibrations of up to 16g

Battery lasting up to three years of battery life

Connection via 3G/4G via Smart Receiver

Communication with up to 100 sensors within 1 kilometer without barriers

Monitoring temperature from -40°C to 120°C

Support low speed from 1 RPM