Built for Maintenance and Reliability Teams Who Can’t Afford Downtime

Too Much Downtime? Not Enough Hands?

Tractian Condition Monitoring lightens the load and keeps machines running.

Built for Maintenance and Reliability Teams Who Can’t Afford Downtime

Tractian Condition Monitoring lightens the load and keeps machines running.

Problems

solutions

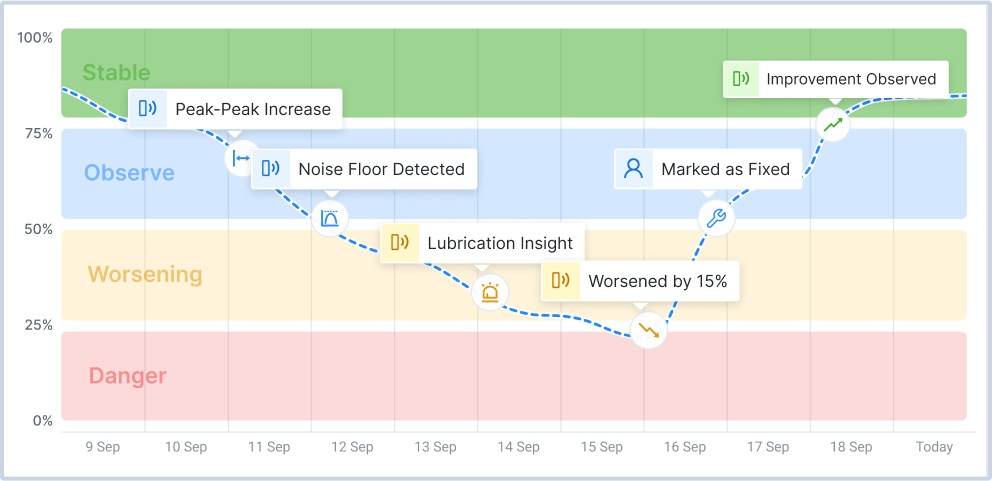

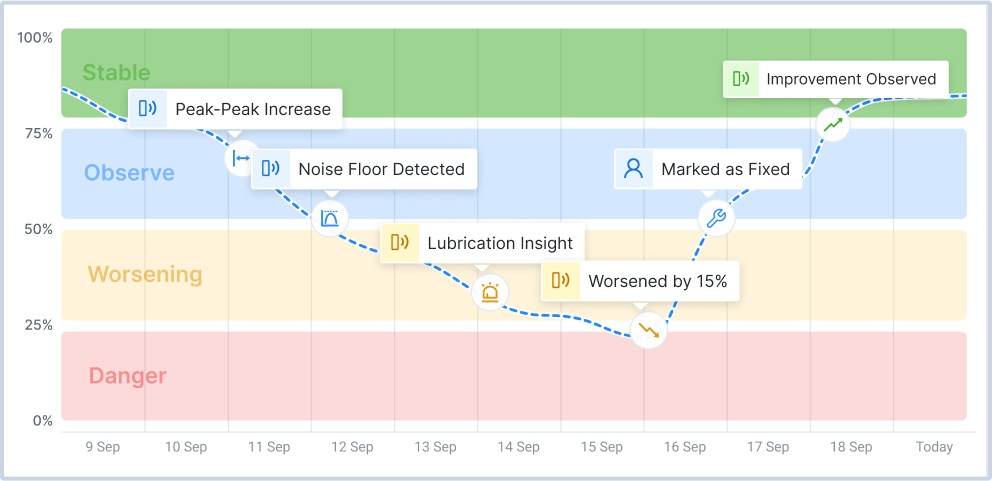

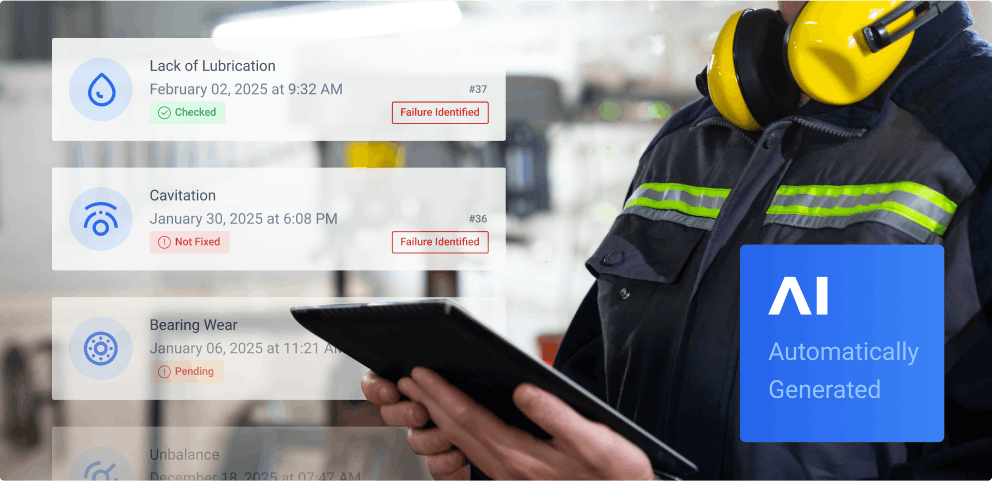

With real-time Condition Monitoring, you’ll see failures coming long before they cause unplanned stops. Our AI-powered system detects early warning signs, diagnoses root causes, and gives you clear, actionable steps to fix issues fast.

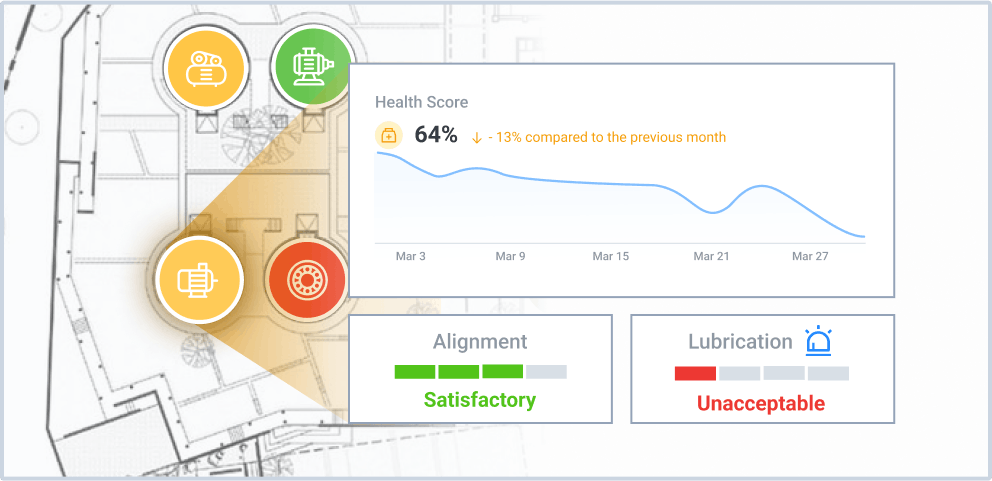

Forget clipboards and complex routes. Our wireless sensors automatically track vibration, temperature, runtime, and RPM across all your machines, updating in real time. Your team gets complete asset visibility—without walking the floor.

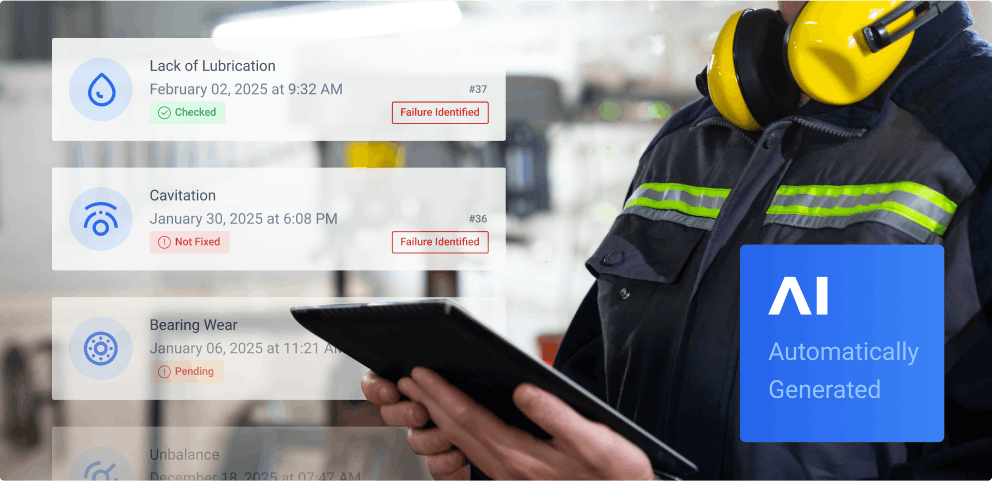

Skilled labor is scarce. Tractian helps you get the most from every worker by cutting out noise and focusing only on what matters. No false alarms. Just precise alerts and clear insights, so your team can act efficiently and effectively.

With real-time Condition Monitoring, you’ll see failures coming long before they cause unplanned stops. Our AI-powered system detects early warning signs, diagnoses root causes, and gives you clear, actionable steps to fix issues fast.

Forget clipboards and complex routes. Our wireless sensors automatically track vibration, temperature, runtime, and RPM across all your machines, updating in real time. Your team gets complete asset visibility—without walking the floor.

Skilled labor is scarce. Tractian helps you get the most from every worker by cutting out noise and focusing only on what matters. No false alarms. Just precise alerts and clear insights, so your team can act efficiently and effectively.

SUCCESS CASE

Jacob Hoffine

Reliability Engineer

”There were some [failures] that I would say, if not for having Tractian, we would have never noticed… For example, a lubrication problem, we could go out and lubricate it and recheck it on the Tractian platform and see that it fixed the problem… It was pretty impressive for that, the results we got early on.”

More Than a Vibration Sensor – A Full Predictive Maintenance Solution

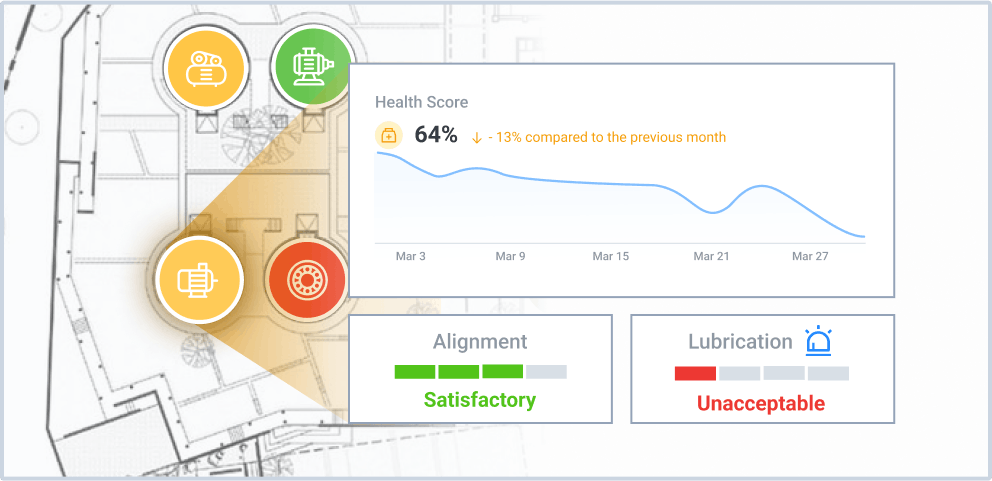

Industrial assets generate unique vibration signatures that change as components wear or develop faults. Tractian’s AI-powered vibration sensors continuously monitor these patterns, providing high-fidelity data on machine health.

Our wireless sensors capture vibration, temperature, runtime, and RPM data from all critical machines—live and around the clock.

Advanced AI models process the incoming data instantly. We detect all major failure modes—including misalignment, bearing wear, lubrication issues—long before they escalate.

Every alert comes with built-in root cause analysis. No false alarms—just clear, prioritized insights so your team knows exactly what’s happening and why.

With precise, actionable recommendations, your maintenance team can make informed decisions,focus on what matters most, and avoid unplanned downtime.

Industrial-Grade, Built for Reliability

Battery Life

3–5 years

Temperature Range

-40°F to 250°F

Connectivity

4G/LTE, up to 330 ft with obstacles, 3,300 ft Line of Sight

Certified for Hazardous Locations

Class 1 Div 1 (ATEX, IECEx, NFPA compliant)

IP69K Rated

Fully sealed & resistant to water and dust particles

TRUSTED BY INDUSTRY LEADERS

Avoided Downtime: 48h

Production Output Increase: 50%

↑ Efficient resource allocation and prioritization of critical assets

FAQ