Condition Monitoring Sensor Engineered for Reliability Teams

Avoid unplanned machine failures and downtime with the Tractian Fault-Finding and Auto Diagnosis™ sensor.

Avoid unplanned machine failures and downtime with the Tractian Fault-Finding and Auto Diagnosis™ sensor.

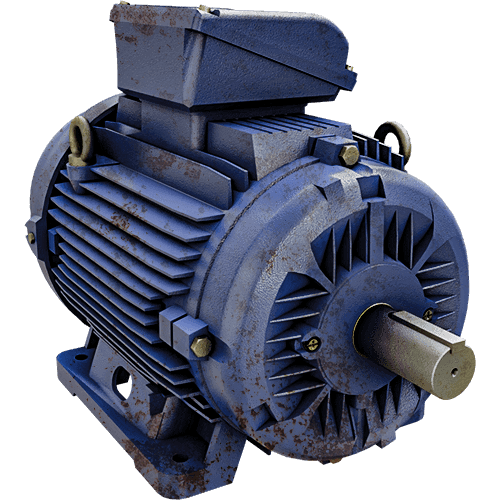

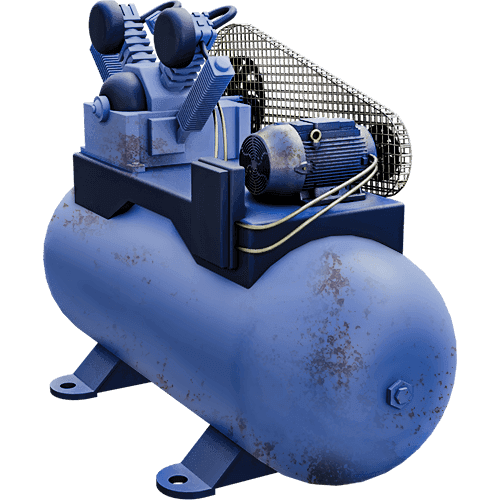

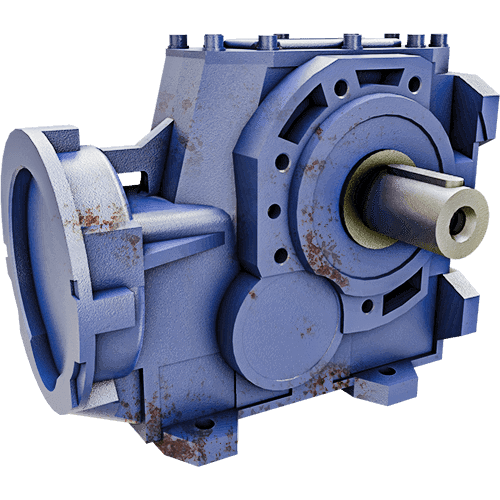

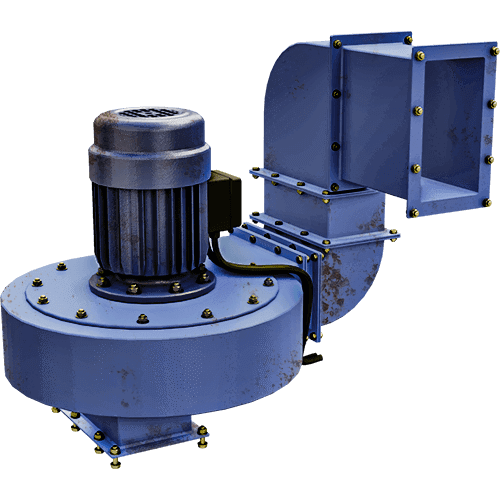

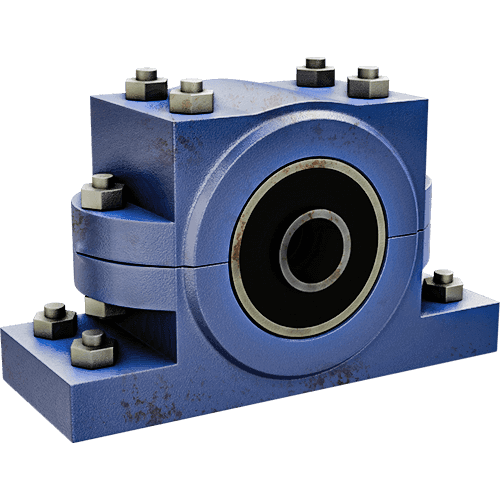

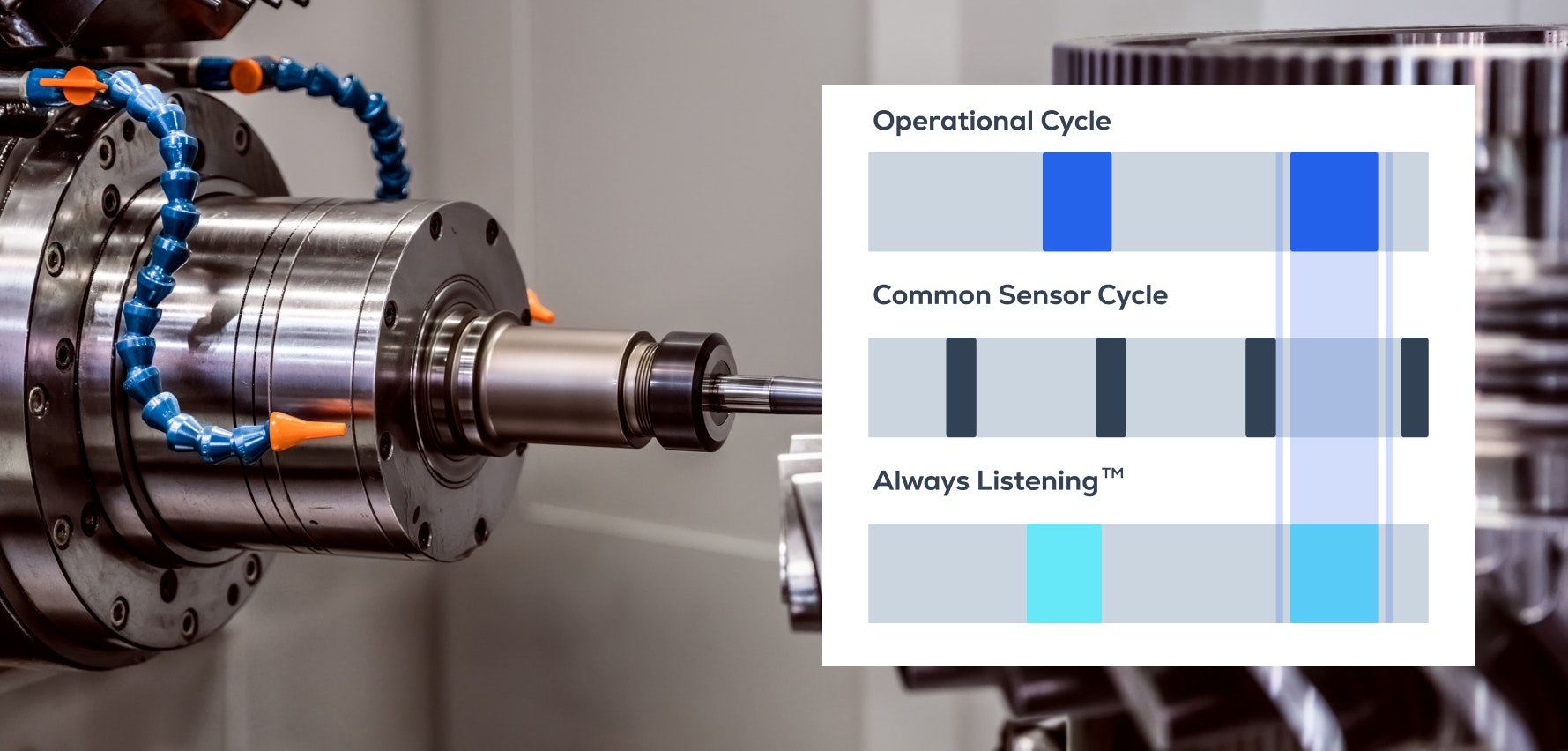

Fits any application, from continuous to intermittent operation machines.

And more...

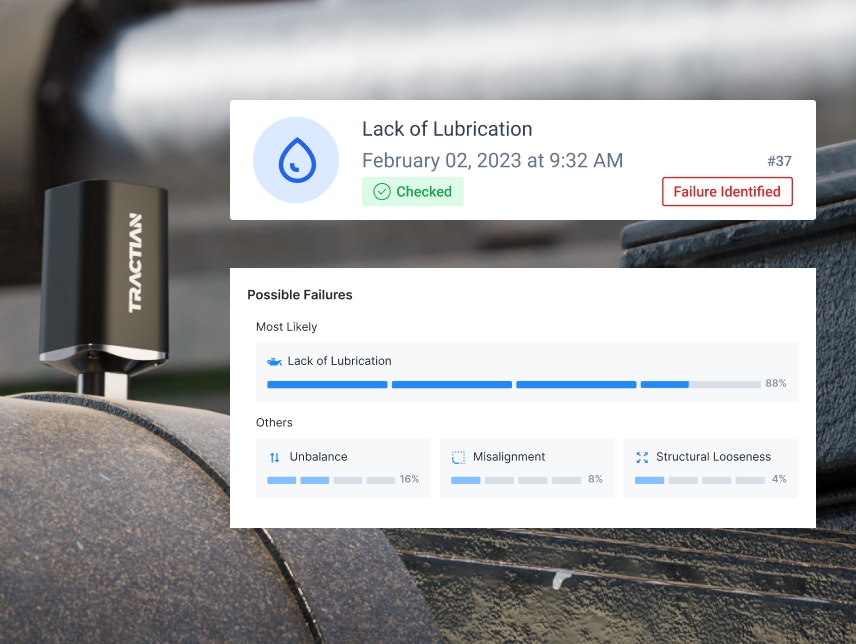

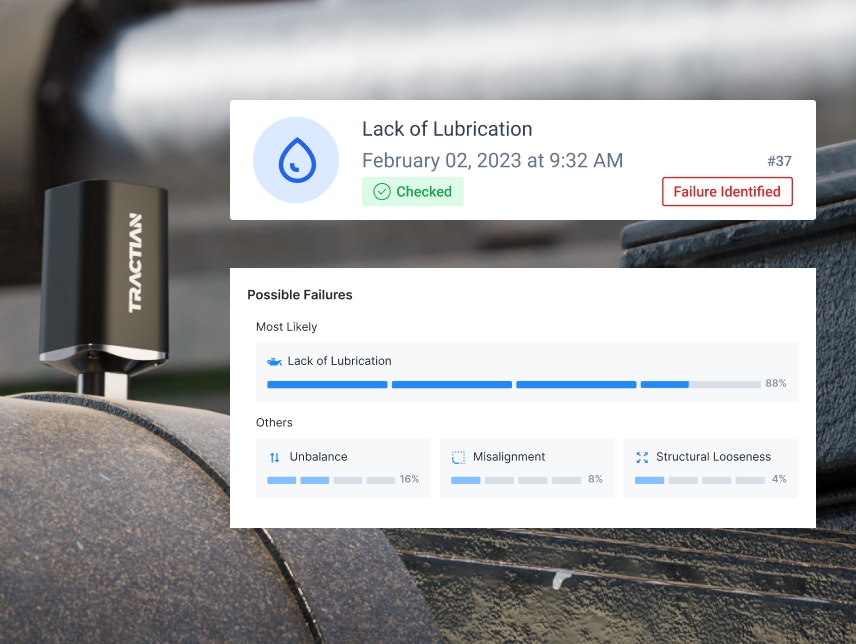

Unbalance, Lubrication, Misalignment, Cavitation, Wear, Bearing Faults, and more.

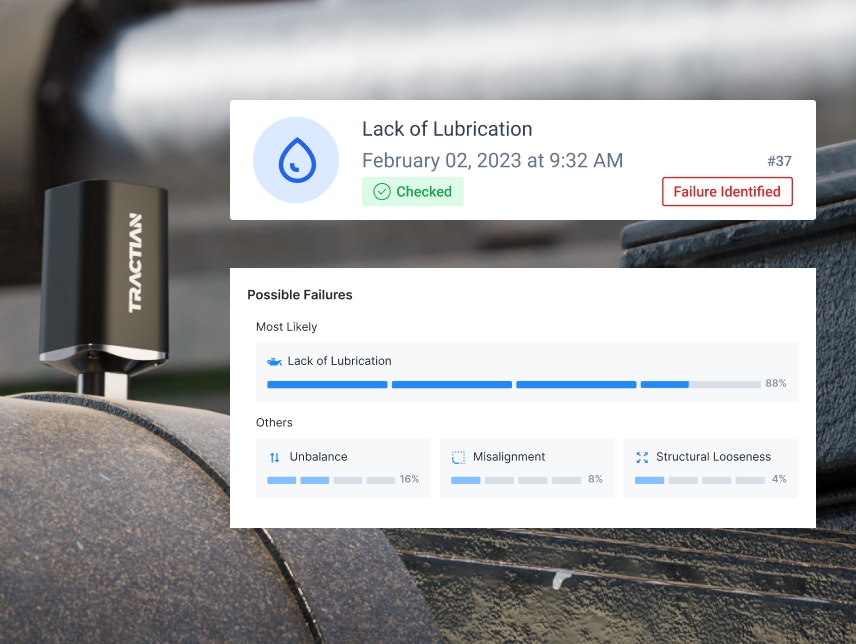

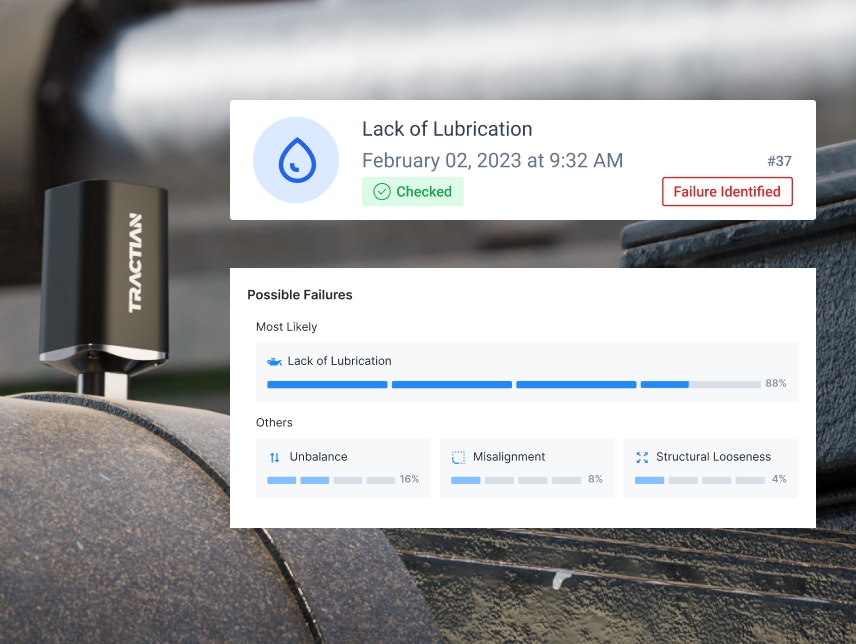

Fault Detected

The sensor detects failures in real time based on sampled vibration, temperature, runtime, and RPM data.

*Based on a survey of 200+ companies with extended experience using Tractian.

Less Maintenance Costs

Increase in Machine Availability

Downtime Reduction

*Based on a survey of 200+ companies with extended experience using Tractian.

Motion detection feature that ensures vibration data is sampled at exactly the right moment without the need for complex scheduling, on machines with intermittent operating cycles and discrete operations.

The sensor accurately analyzes assets through a unique algorithm that identifies rotation between 1 and 48,000 RPM in real time based on the sampled vibration.

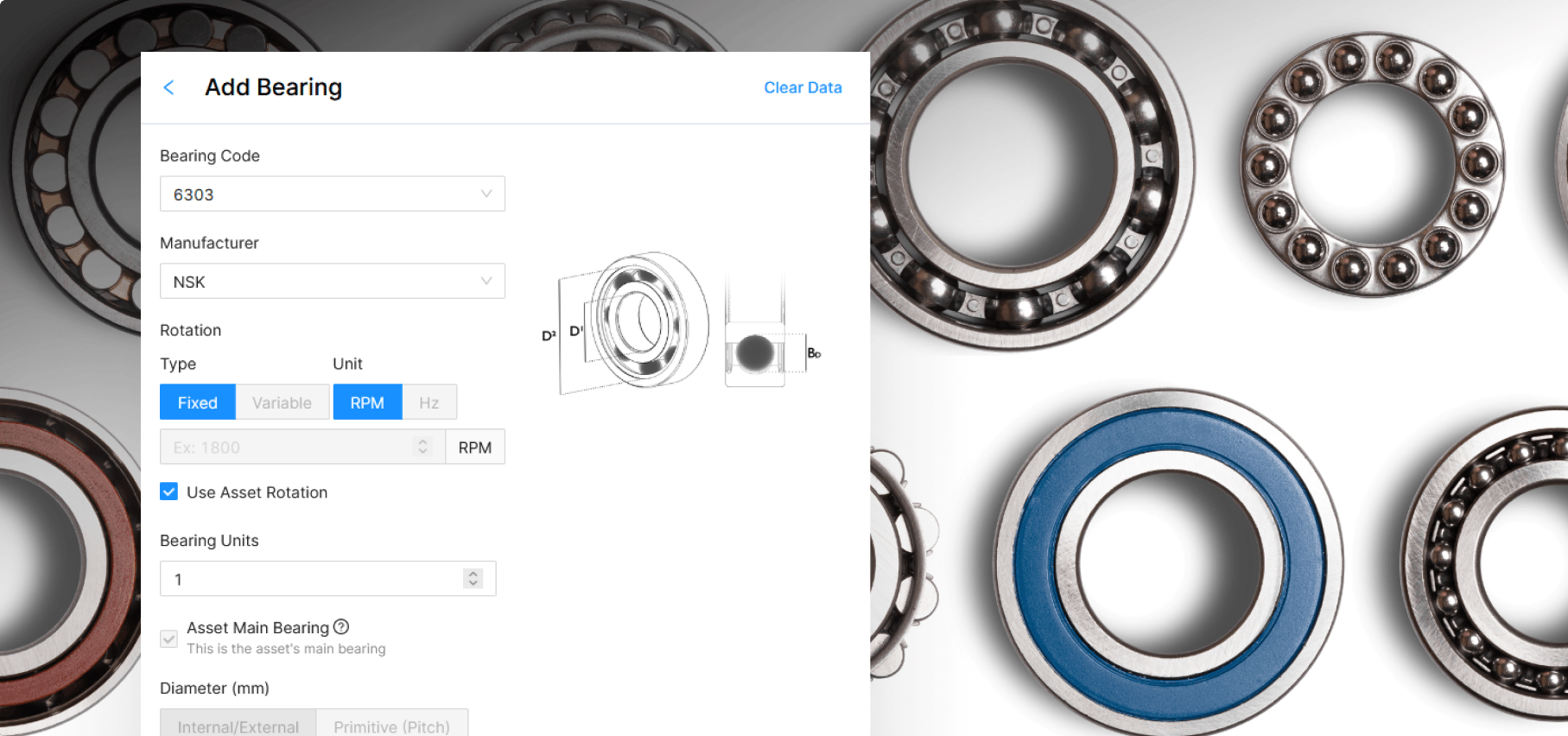

Autocomplete bearings database has over 70 thousand types of bearing models to fill in parameters like BPFI, BPFO, and BSF, all automatically.

Communication of up to 330 ft with obstacles or 3,300 ft in an open field.

Monitoring Temperature from -40°F to 230°F

Certified for Hazardous Locations (ATEX, IECEx, and NFPA)

Easy-to-use with 4G/LTE Connectivity

Case Study

One of our assets is key to our plant: if it fails, it causes two thirds of production to shut down. That asset was flagged for a bearing issue by the Tractian system. Without Tractian being able to tell us that, we might have gone through the shutdown with the same asset and that same bearing. Tractian has really improved our asset availability.”

Senior Reliability Engineer

Prior to embracing Tractian solutions, the Food & Chemical giant relied heavily on reactive maintenance and faced frequent unplanned downtimes.

Through a strategic business partnership, CP Kelco achieved remarkable outcomes:

$432K in savings and reduced breakdowns, thus resulting in less unplanned downtime.

End of asset downtime and unexpected failures.

+297% ROI assured within 12 months.