Take the first step towards putting an end to high costs in maintenance

Only with TRACTIAN you can detect failures, get automatic insights, and centralize the management of maintenance activities and staff in a single tool.

The all-in-one platform to monitor your assets remotely

Prevent failures in your machines and leave downtime in the past with the best predictive system on the market.

Do you feel like you don't control your machines' performance as you wish?

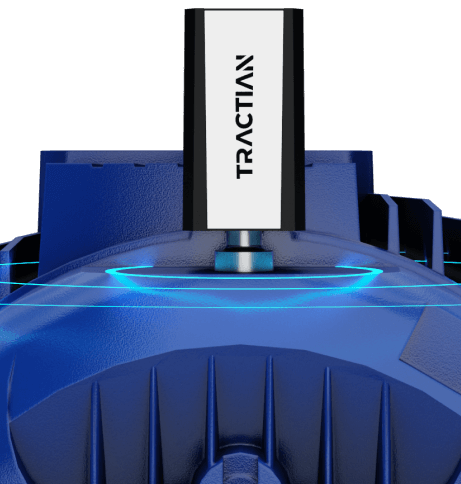

Meet TRACTIAN's smart sensor for vibration and temperature that will keep your assets running uninterrupted.

Automatic Failure Detection

Our sensor detects the slightest anomalies and lets you know at the very first symptoms.

Real-time data

Get reliable insights 24 hours a day, 7 days a week.

Assured Security

The data is sent directly through our 3G/4G network, no Wi-Fi required.

Constant monitoring

When a failure is about to happen, you get notified right away.

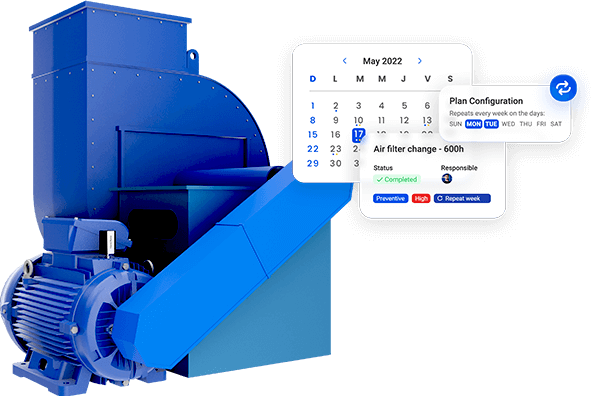

Your maintenance plan like you've never seen before

Reduce

maintenance costs

Increase

the uptime of your machines

Reduce

the number of unexpected breakdowns

How does it work?

Get all this in less than 5 minutes. With TRACTIAN, this is possible, thanks to our Plug & Play technology.

1

We ship the sensors and help you choose the best monitoring points.

2

Instant activation. Stick the sensor to your machine like a regular bandaid.

3

Your machines are safe, guarded by the most advanced artificial intelligence on the market.

Compatible with more than 30 asset classes

Motors

Unbalance, misalignment and resonance failures can be identified.

Bearings

Of the most diverse types, identify problems like mechanical looseness and foundation failures.

Compressors

The vibration analysis detects wear and overload on the shaft, among others..

Pumps

The sensors detect signs of excess temperature and unbalance.

AHU's

Detect heating and engine defects.

Fans

Misalignament of belts and bearing defects can be noted.

Press

Identify failures in the servo motors, steering wheels and friction in joints..

Gearboxes

Unbalance, misalignment and bearing issues are automatically detected.

Turbines

Detect unbalance and interlocking.