Online Predictive Maintenance with constant diagnostics

Eliminate unexpected breakdowns between offline data collections once and for all. Meet the online system that detects potential failures and warns you on the fly.

The ones who compare, choose TRACTIAN

No more relying on periodic inspection routes, random preventive maintenances, and traditional vibration analysis tools. Learn about the advantages of our IoT sensors combined with Artificial Intelligence:

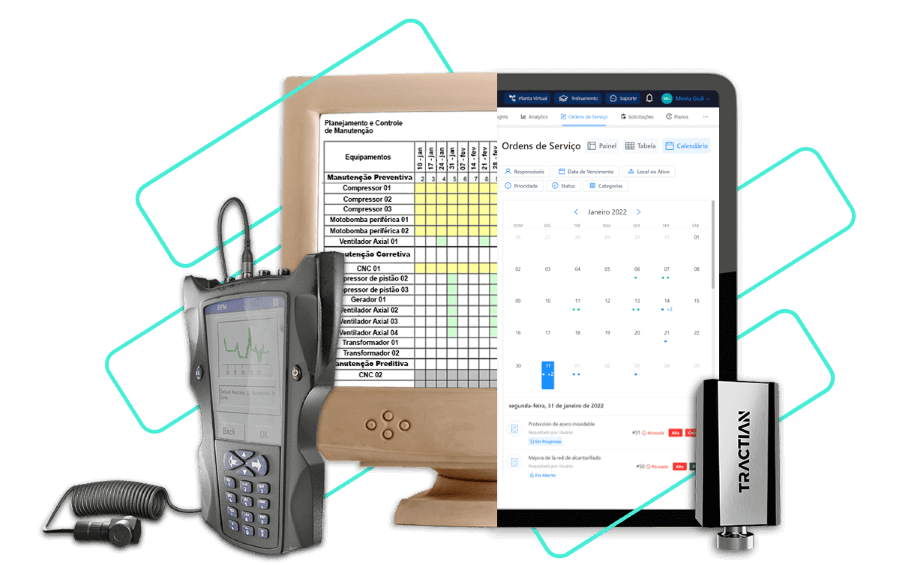

PREDICTIVE MAINTENANCEOffline

Vibration Collector

As the name implies, it only measures vibration

Long time to implement and get started

Requires displacement for reading in the field, respecting the acquisition cycle

Manual data analysis

Can only be done by qualified professionals

Difficulty in organizing papers and spreadsheets

Errors and erasures are common and can hinder decision making, especially the definition of preventive inspections

Outsourced maintenance

Periodic inspection routes (often monthly)

Data needs days to be processed and returned by the specialist

Process is concentrated in the outsourcing company

PREDICTIVE MAINTENANCEOnline

Smart Trac

Measures vibration, temperature, hour meter, and energy

Immediate installation and data collection

No bluetooth connection needed and works alone

Automated diagnostics

Artificial Intelligence analyzes the data and turns it into automatic alerts

Organizes and stores data in the cloud

Precise and strategic information for MPC and the generation of preventive maintenance tasks

Condition Monitoring

Data collection every day of the week, 24 hours a day

Data available to the team automatically and without storage limit

Everyone can access the platform and plan maintenance tasks based on its data

At what stage of the evolution of predictive analytics are you?

Screwdriver

Method in which the expert approaches the asset with the key and uses his senses to evaluate the vibration.

Stethoscope

It measures more accurately, but it also requires an expert to get close to the asset.

Electronic Stethoscope

It is more precise than the previous one and can be used by any technician, expert or not.

Vibration Collectors

Very well known, they depend on specialized technicians to measure and analyze.

Smart Trac

Sensor that collects and analyzes data online, independently and 24 hours a day, without requiring infrastructure or handling by technicians.

Learn about the evolution for your maintenance!

Invest in the online predictive strategy that will actually increase the reliability and availability of your assets, save your staff time and effort, and make your maintenance more efficient.

For the maintenance of all industries, companies and businesses

Approved by the sponsors

Some of the largest industries in Brazil have chosen to rely on TRACTIAN's predictive system - and nowadays they wouldn't trade it for anything.

Tiago Junqueira

Maintenance Supervisor at AmstedMaxion

I have no doubt that the technology developed by TRACTIAN is something that really supports and becomes an essential in maintenance. The support platform says the right thing at the right time.

Fernando Vicente

Maintenance Leader at Corteva Agriscience

”Other solutions would have required me to invest in infrastructure, and I did not want to have this initial expense. TRACTIAN's ease of implementation was what motivated me to choose the company, as well as the Artificial Intelligence behind the monitoring, which contributes a lot to identify failures and anticipate them.”