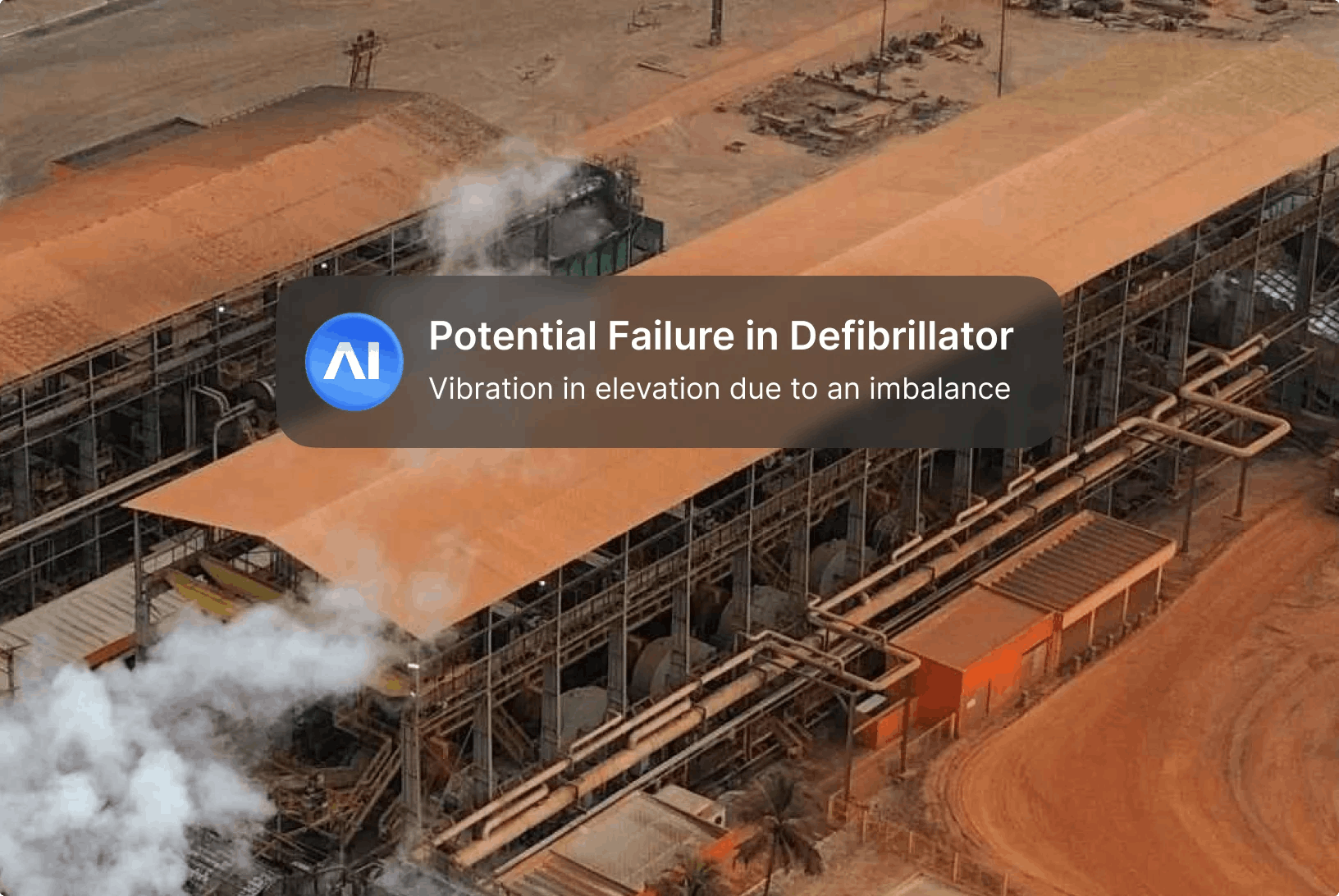

MILLS & AGRICULTURE CMMS AND CONDITION MONITORING SENSORS

Reliability That Keeps Up With the Season

From harvest to off-season, Tractian’s AI-powered maintenance solutions keep your critical equipment running, your team aligned, and your production on track.