MINING CMMS AND CONDITION MONITORING SENSORS

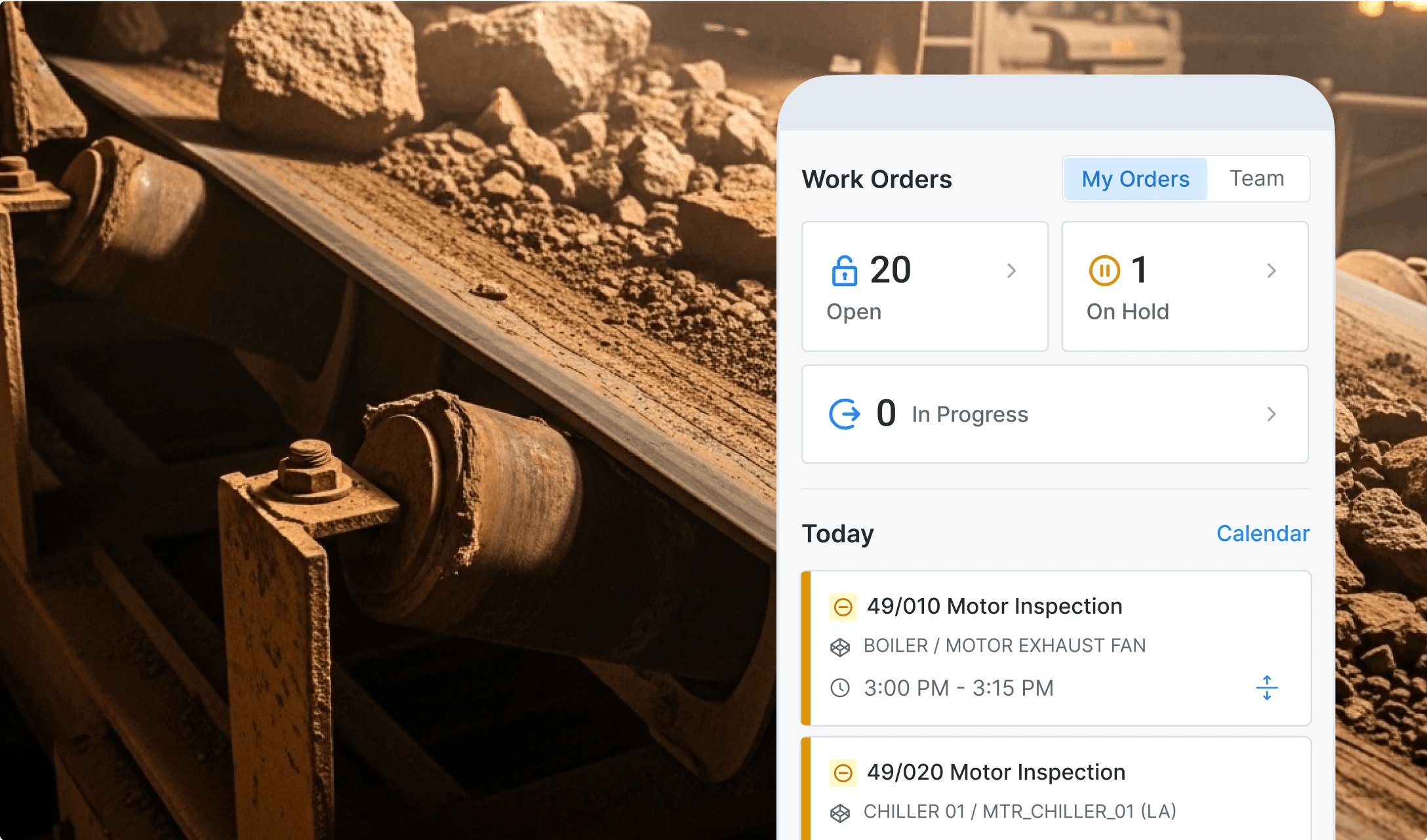

Keep Equipment Going, Above & Below Ground

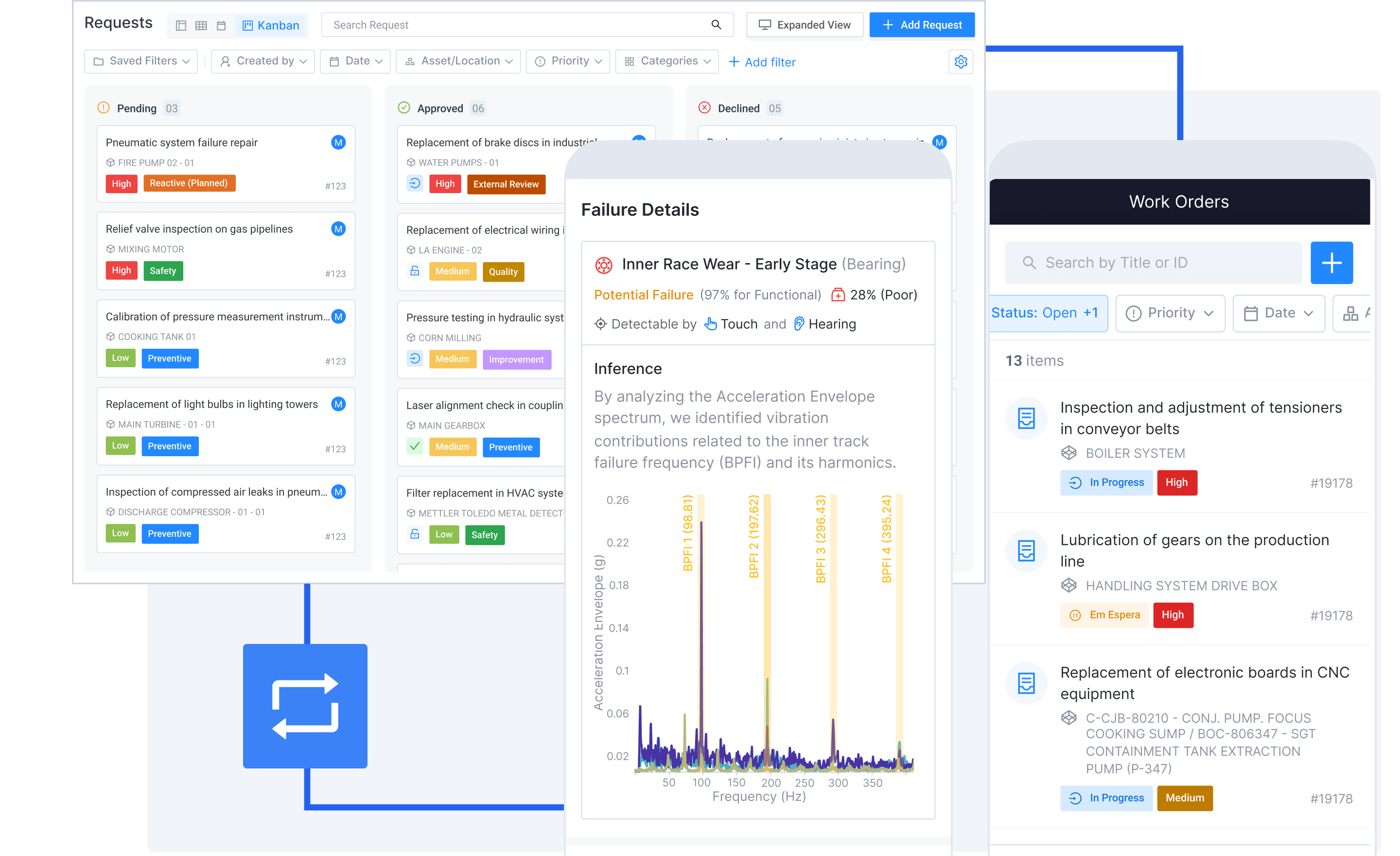

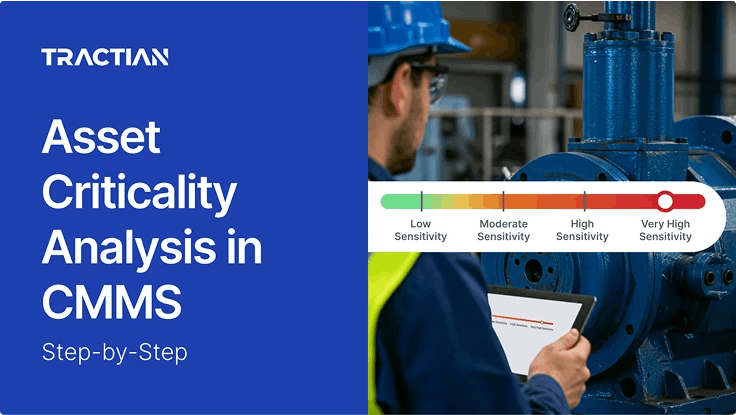

In mining operations, equipment uptime and safety are critical. Tractian combines an AI-powered CMMS with real-time condition monitoring to help teams prevent breakdowns, reduce unplanned downtime, and keep assets running strong in the toughest environments, whether on the surface or deep underground.