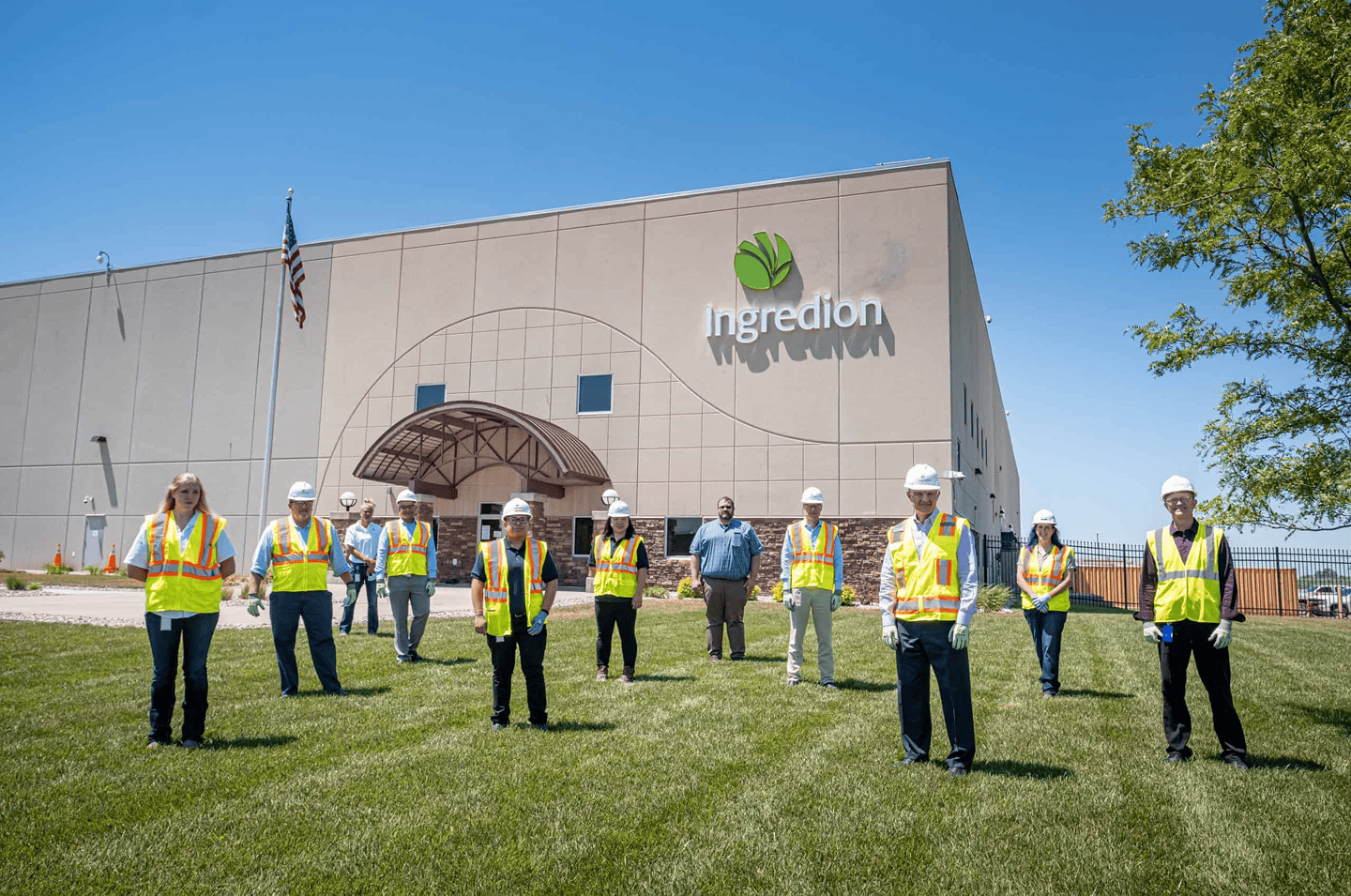

Ingredion Adopts AI to Detect Failures and Boost Machine Uptime

How real-time condition monitoring helped Ingredion avoid critical downtime and save over $1M at just one plant.

How real-time condition monitoring helped Ingredion avoid critical downtime and save over $1M at just one plant.

Read their story

Kraft Heinz Cuts Corrective Motor Repair Costs by 53% with Condition Monitoring

ICL Increases OEE by 41% and Recovers 400+ Tons of Production with Condition Monitoring

Ingredion Adopts AI to Detect Failures and Boost Machine Uptime

Sherwin-Williams Improves Asset Management and Gains Predictability with Condition Monitoring

Whirpool Saves Over $1 Million with Condition Monitoring

From CMMS to Condition Monitoring: How Lyka Built a Proactive Operation

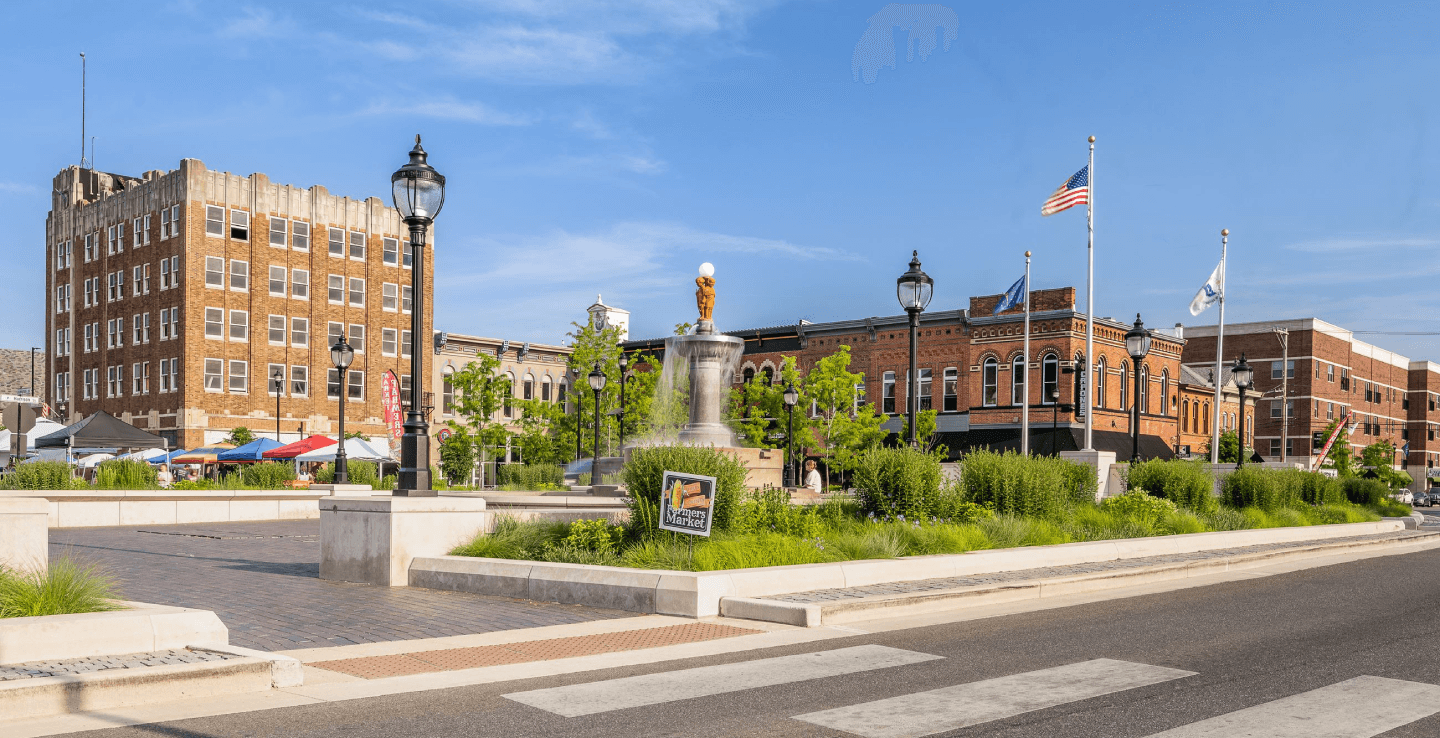

Shelbyville Parks: Bringing Structure to Citywide Maintenance

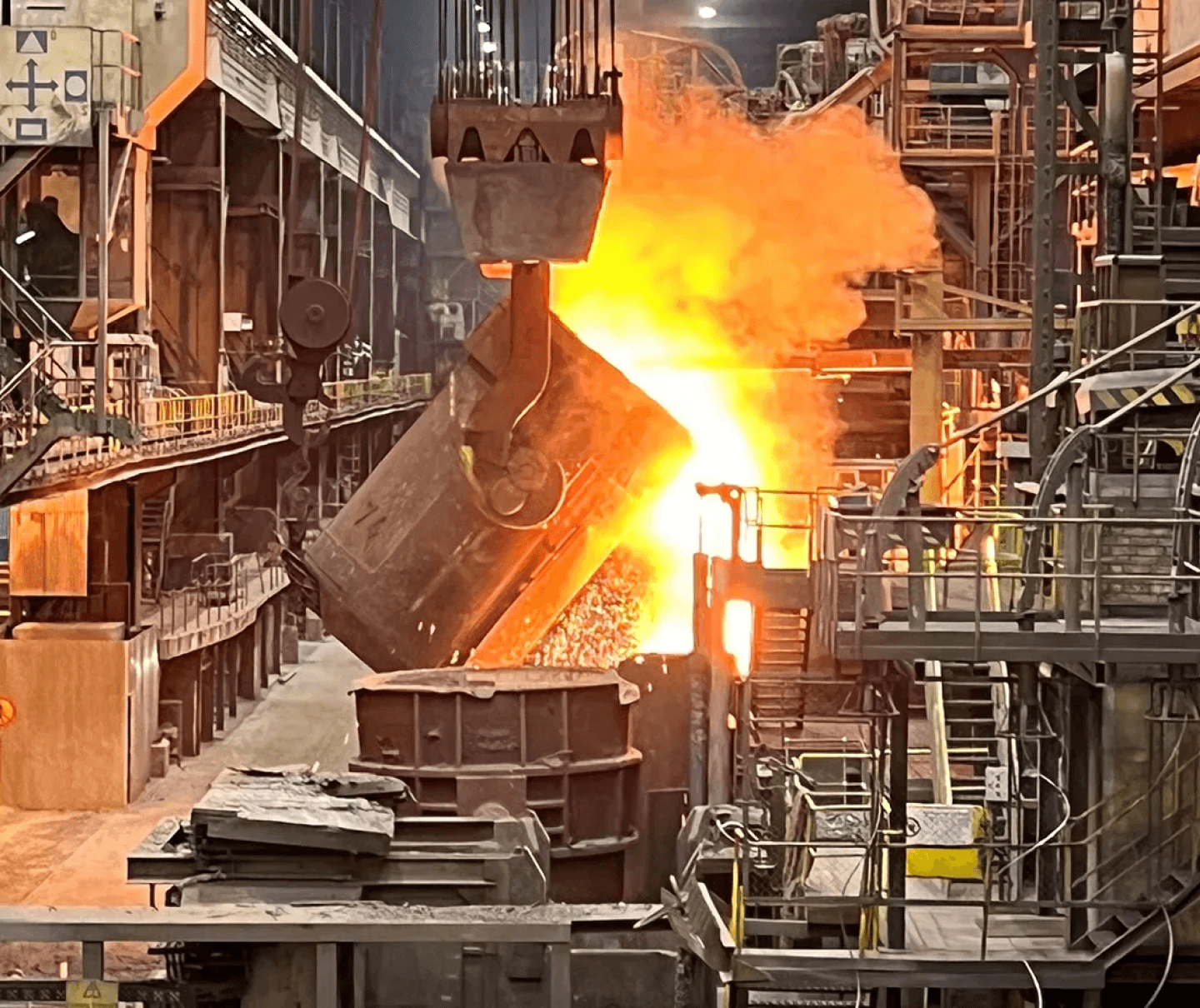

Höganäs Boosts Field Performance with Digital Asset Access and Technical Excellence

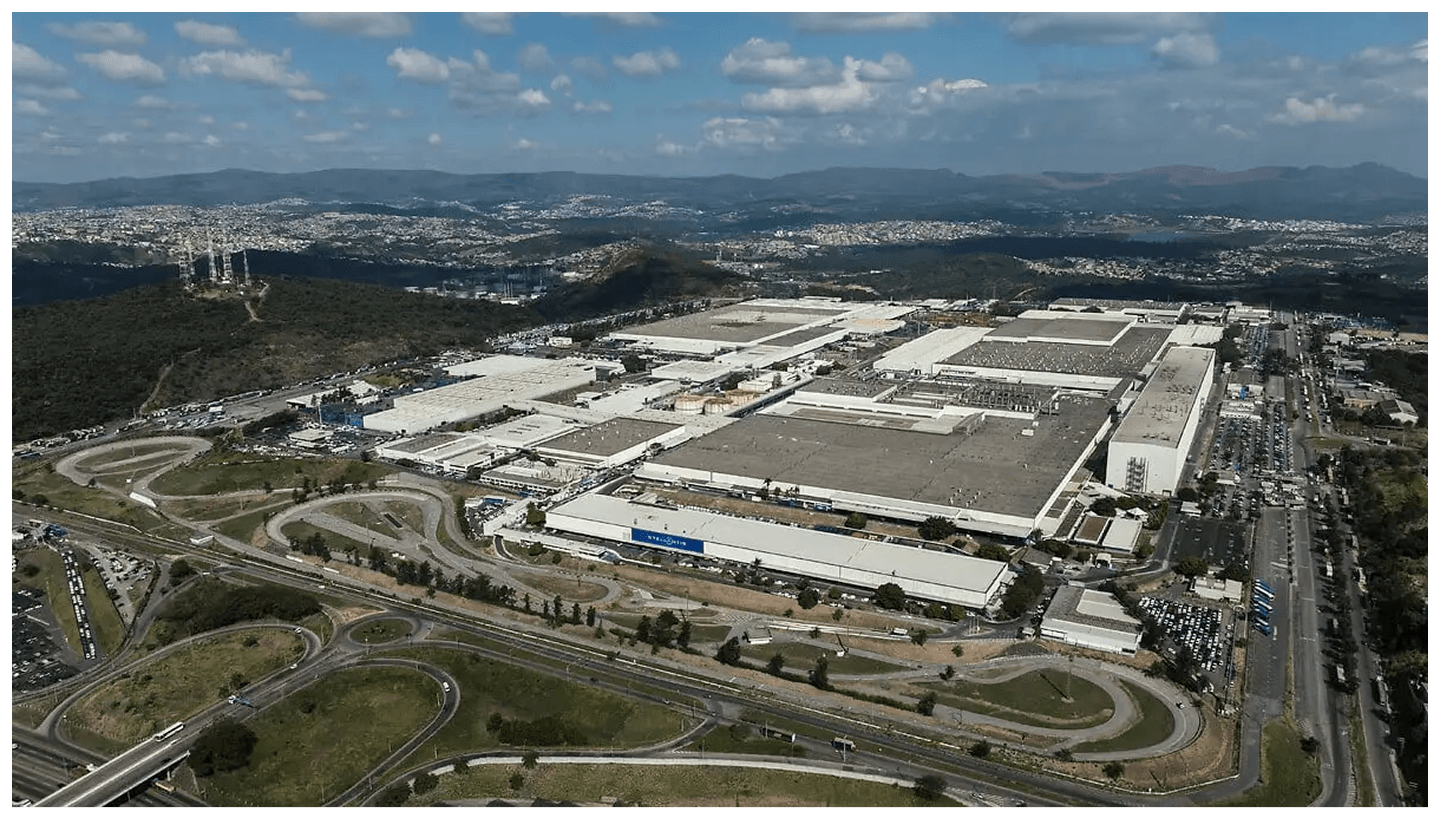

Stellantis Leads the Way in Energy Efficiency for Automotive Welding with Real-Time Monitoring