PREDICTIVE MAINTENANCE SOFTWARE

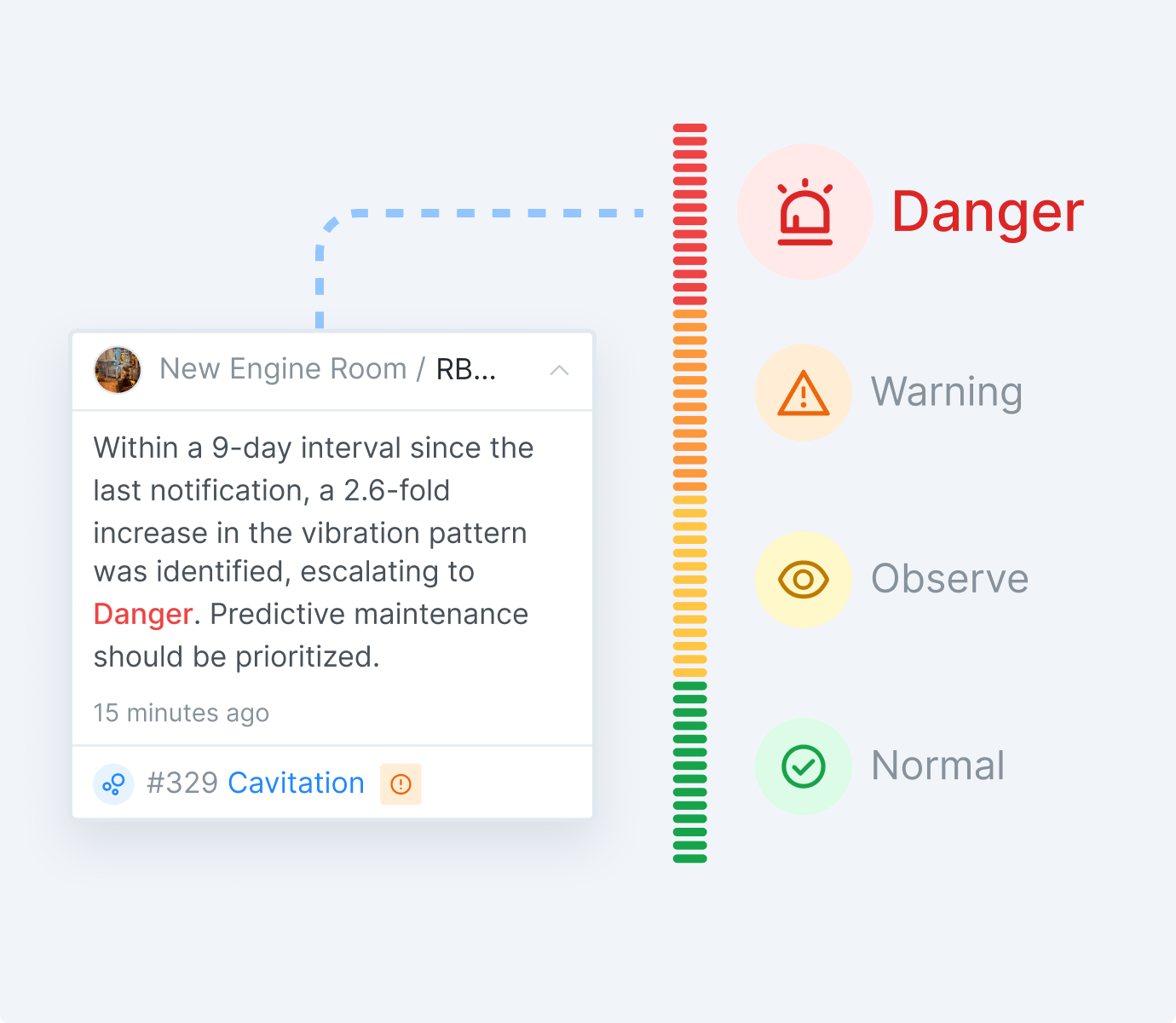

Get ahead of failures and

streamline your strategies

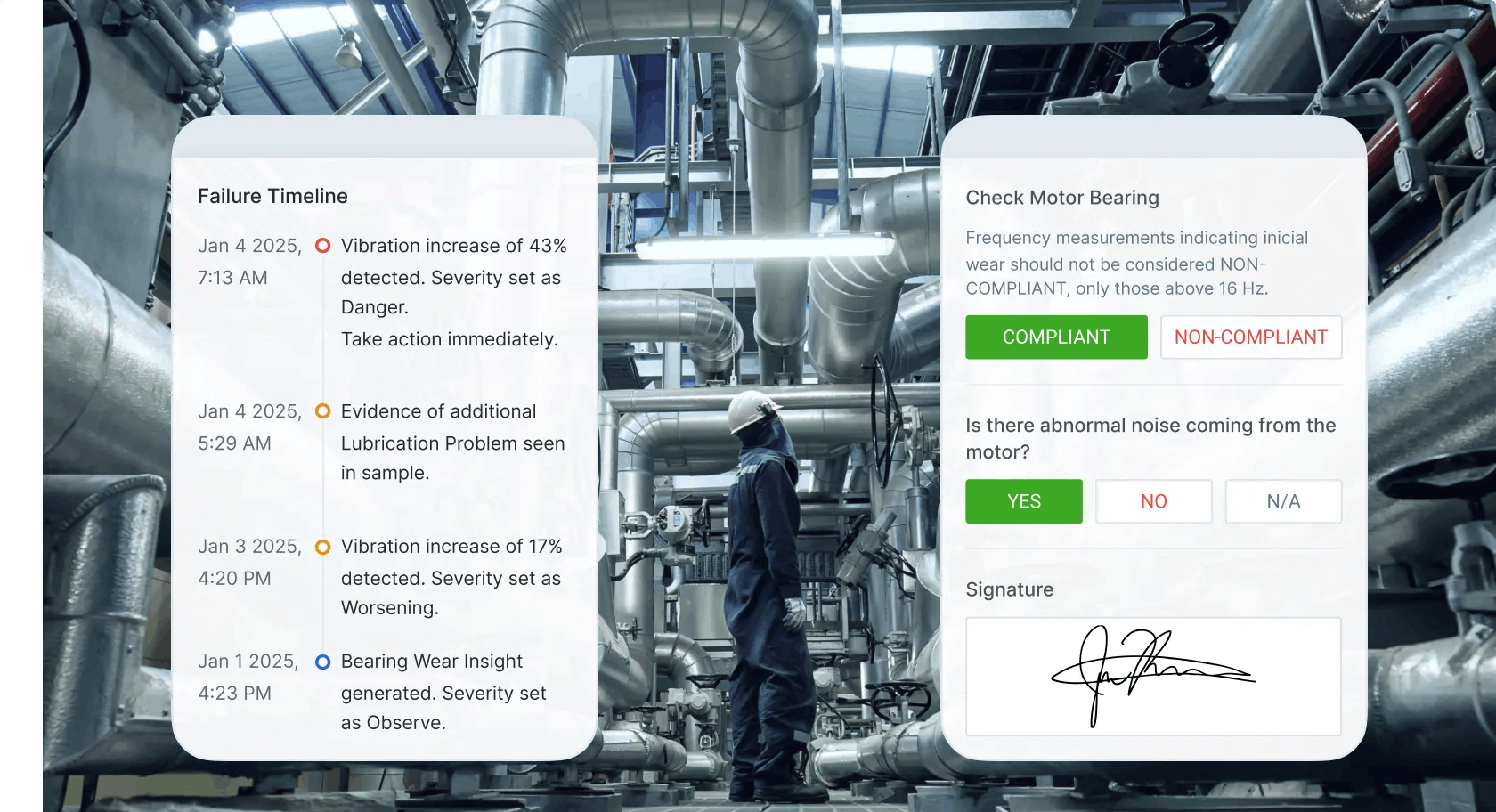

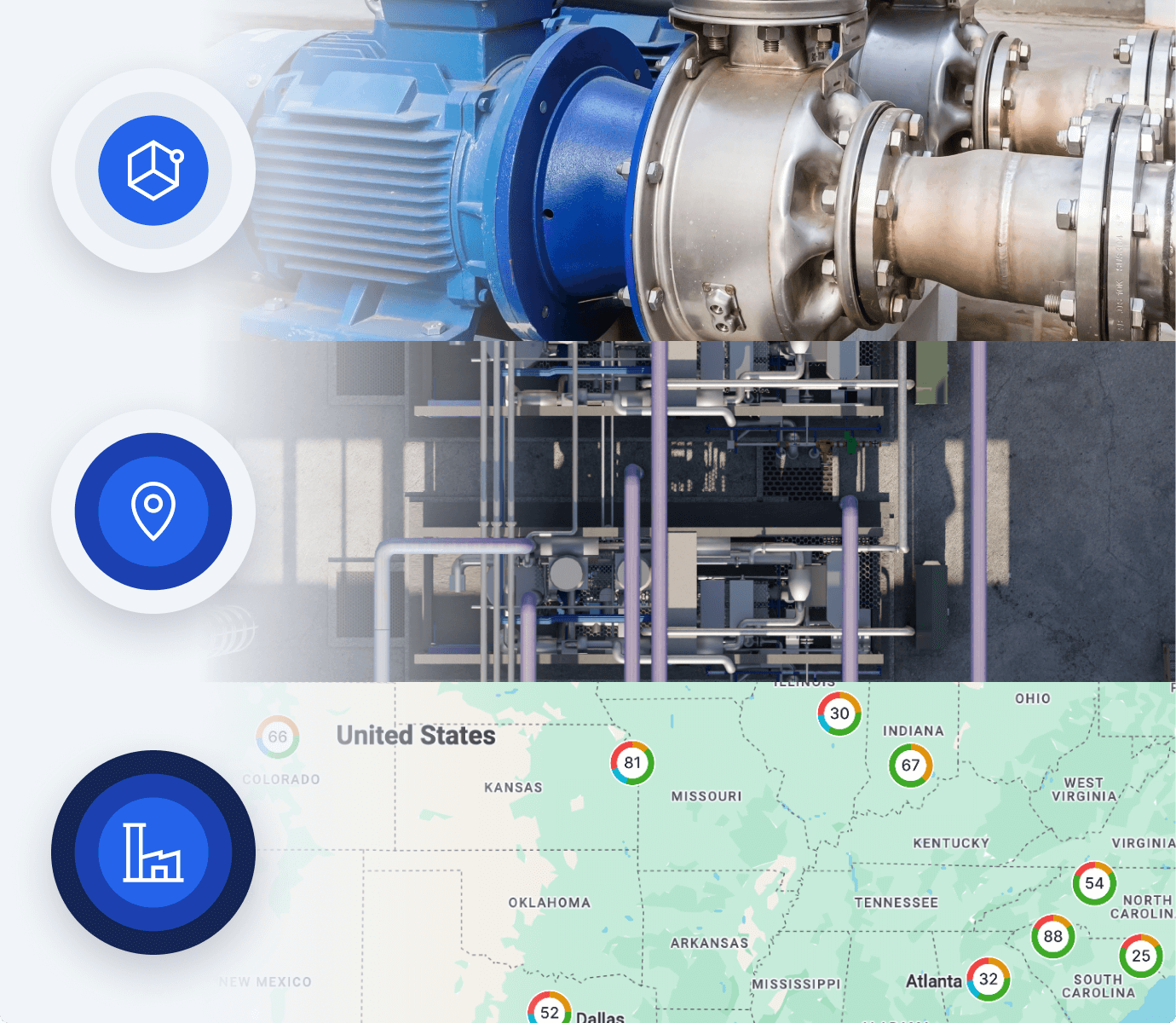

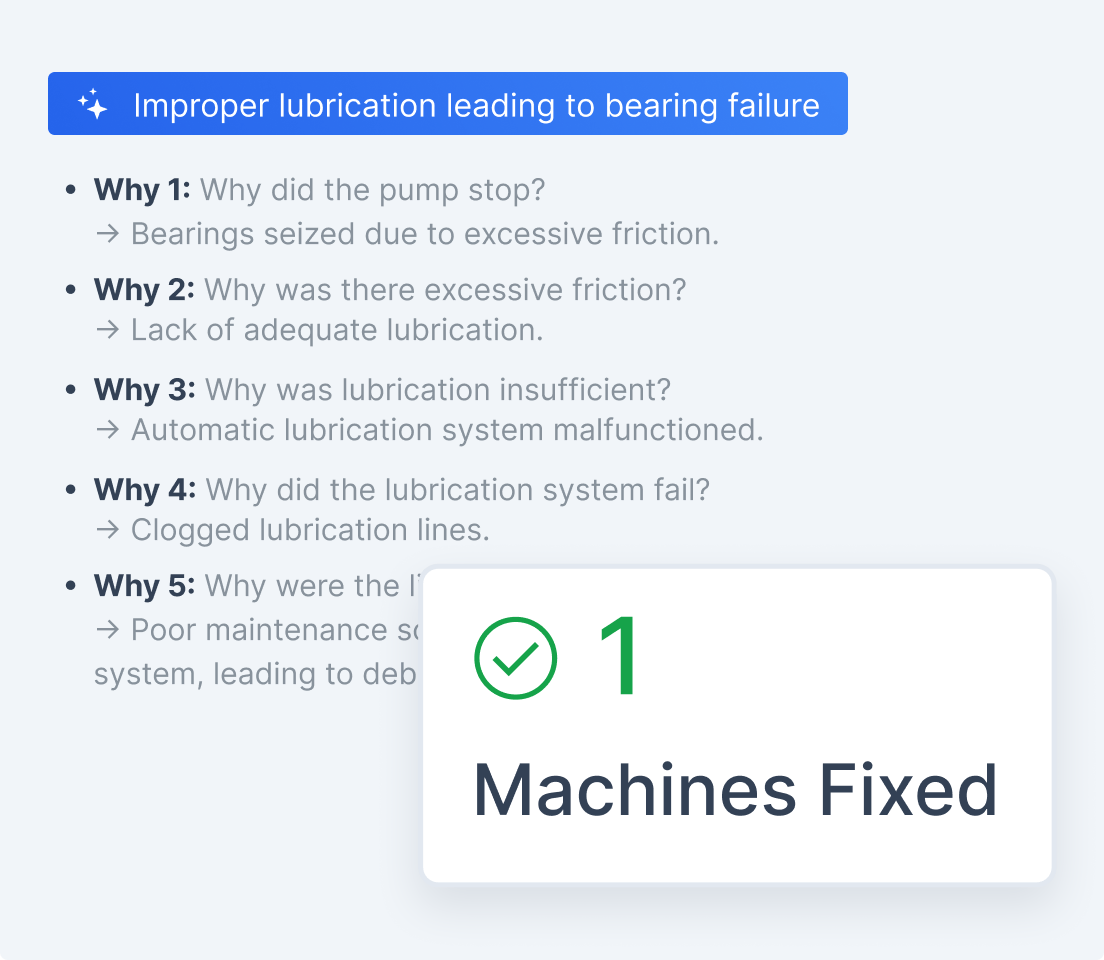

Stop wasting hours on reactive fixes and over-maintenance. With real-time machine monitoring and smart maintenance planning, your team can detect failures early, act faster, and focus on what really matters.