BUILT-IN ROOT CAUSE ANALYSIS

Reliability that

works for you

Turn live condition data into clear root causes, prioritized actions, and proof your strategy is working—plant-wide.

Reliability that

works for you

Turn live condition data into clear root causes, prioritized actions, and proof your strategy is working—plant-wide.

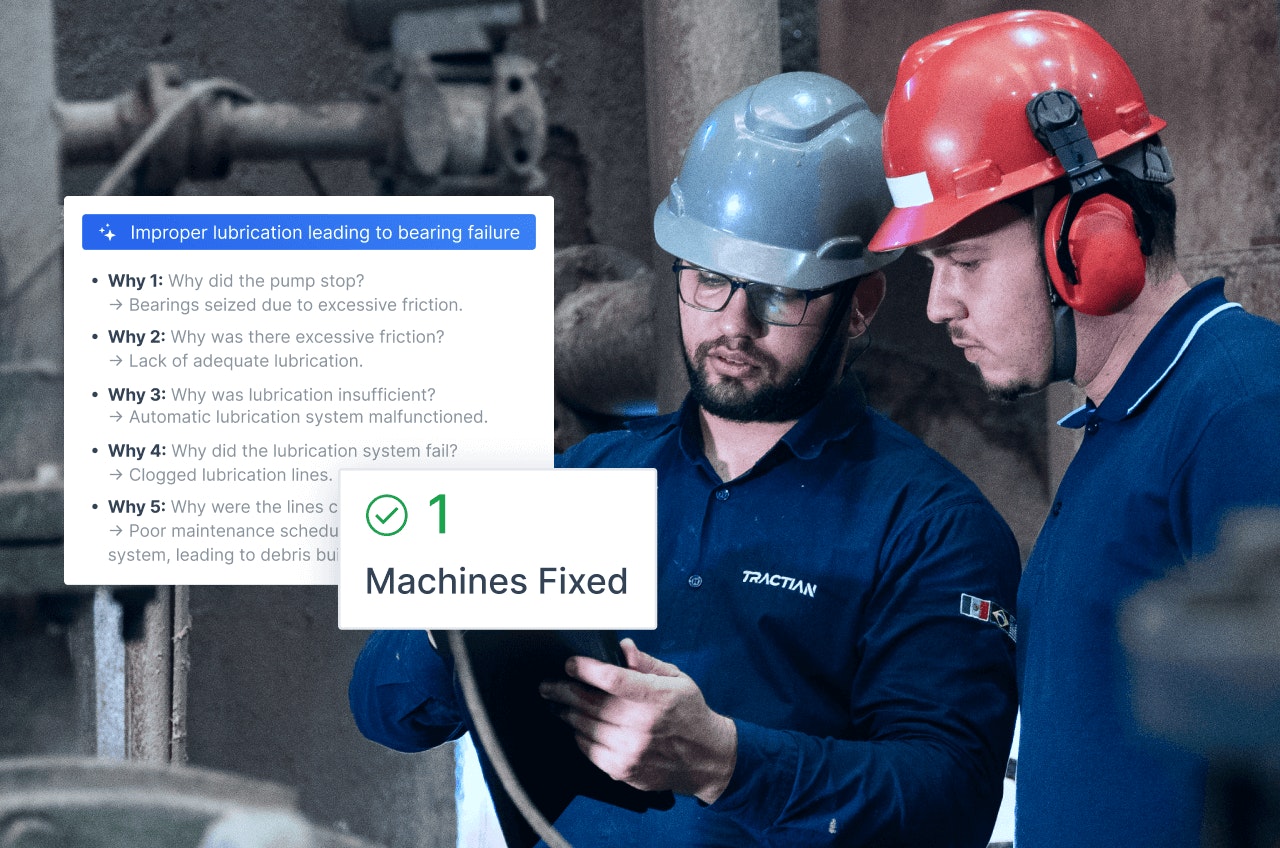

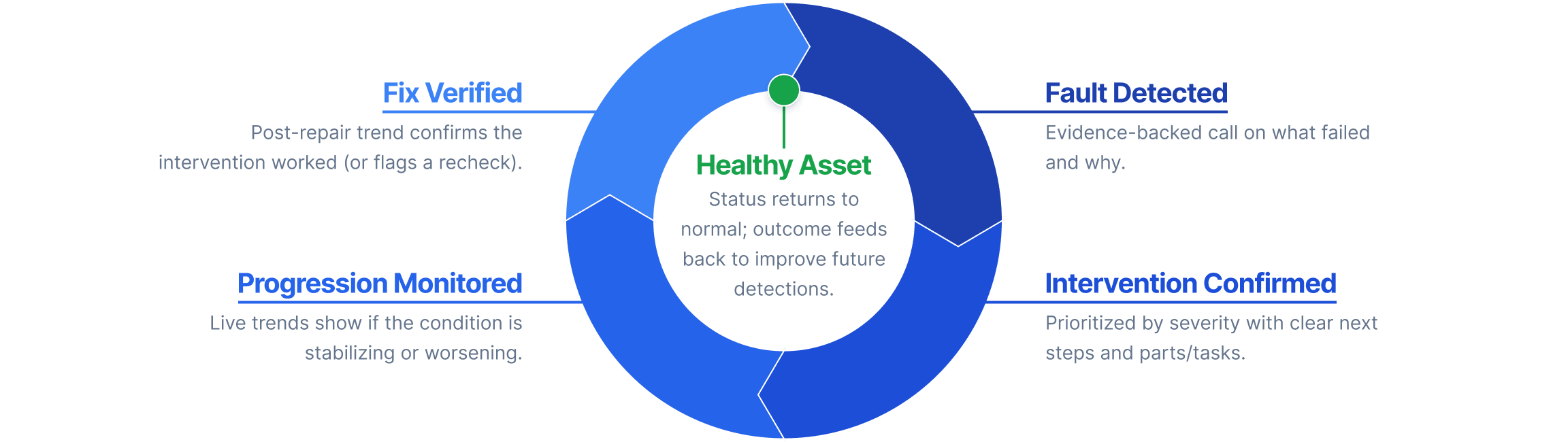

Detect & Gather Evidence

Sensors capture real-time vibration, temperature, RPM, and runtime—no routes required. Spectral analysis and fault-frequency markers turn raw signals into documented evidence you can trust.

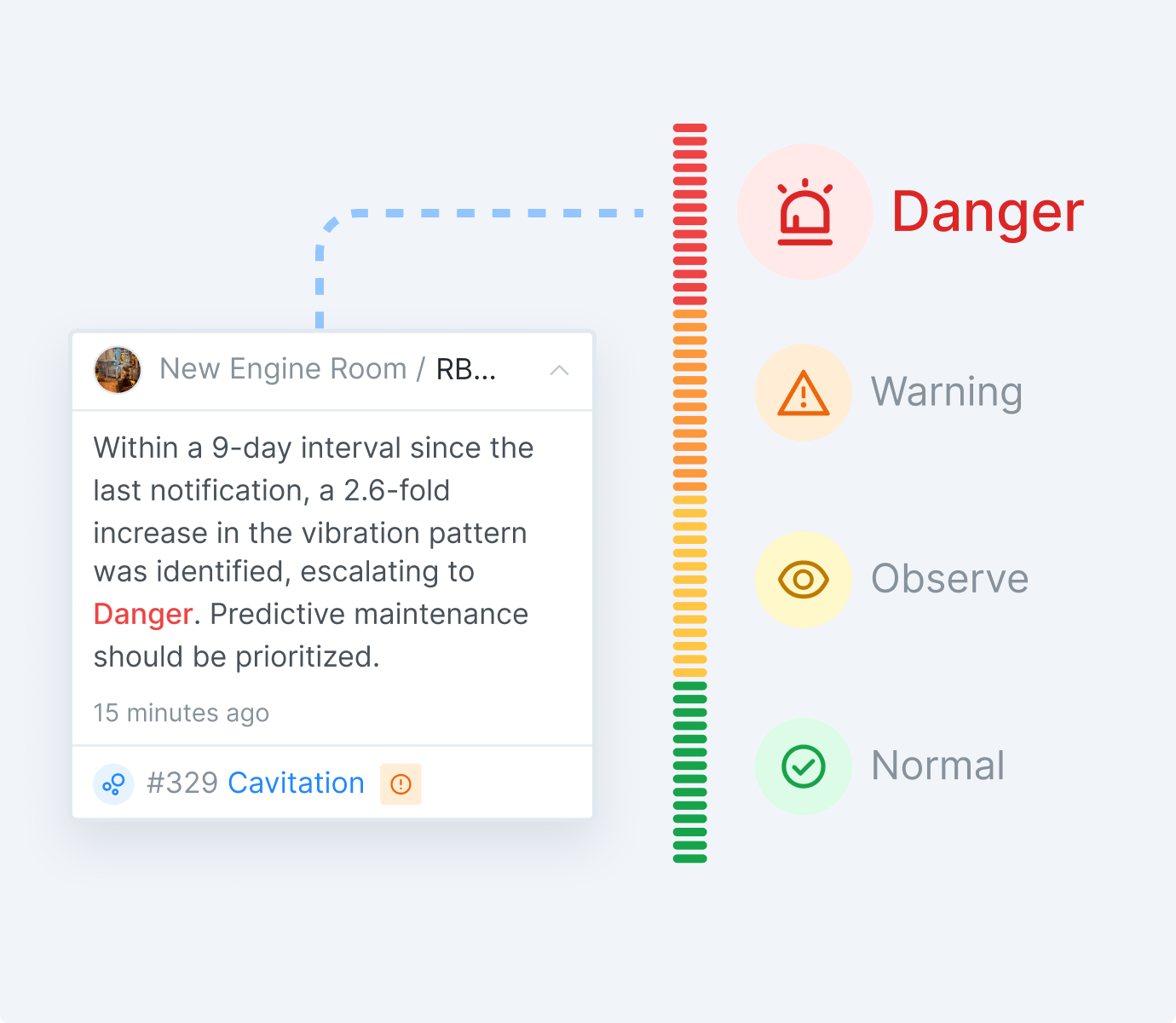

Diagnose with Context

Your data is benchmarked against millions of machine-hours and bearing libraries to identify the likely failure mode and stage. Each insight shows why the call was made with trends, spectrum, and component markers.

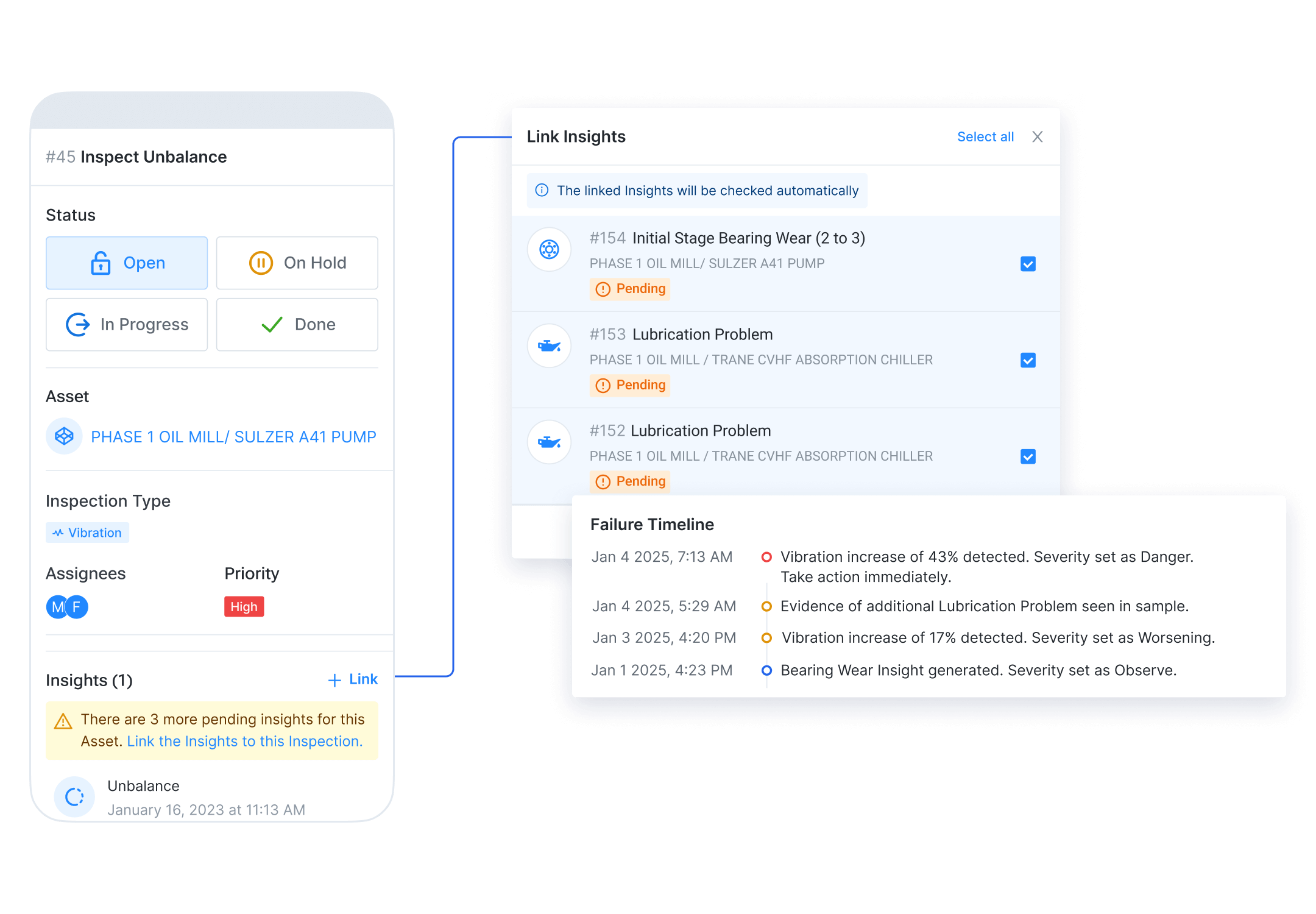

Link to Action

Alerts are prioritized by severity and asset criticality, then translated into next steps—SOPs, parts, and work orders—so the right task gets to the right tech fast. Floorplans and dashboards keep status visible plant-wide.

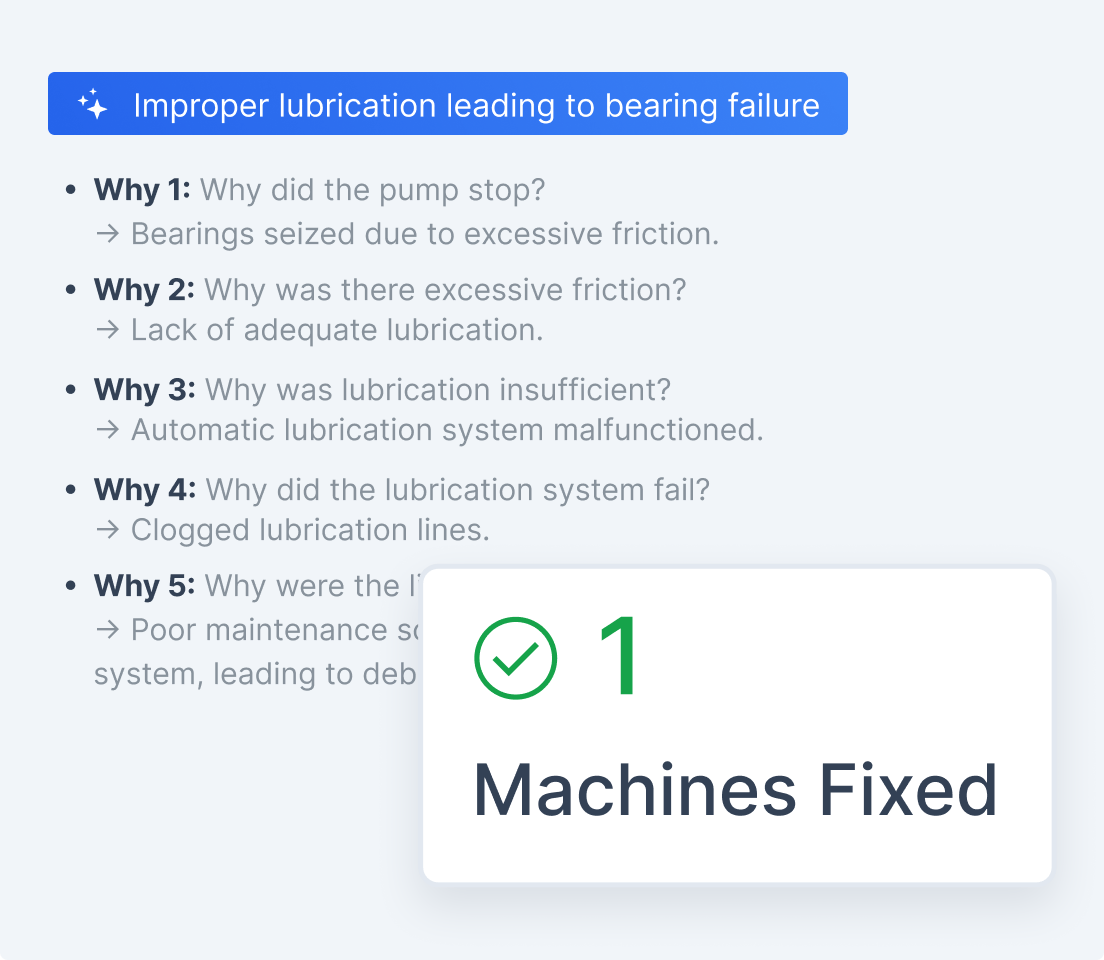

Verify & Learn

Post-repair trends confirm the fix (or flag a recheck) and return the asset to “healthy.” Your feedback and outcomes feed the models, reducing noise over time and improving future detections.

From alert to verified fix to a healthy asset—Tractian drives the whole cycle.

CASE STUDIES

Teams use Tractian Condition Monitoring to catch faults early, cut downtime, and prove the fix—at scale.

$1.0M

in production savings

168 hours

of avoided downtime

“There were some issues that I would say, if not for having Tractian, we would have never noticed… It was pretty impressive for that, the results we got early on.”

Jacob Hoffine

Reliability Engineer

24/7 monitoring

increased operational reliability

“Tractian has allowed us to move from firefighting mode to proactive maintenance. We can plan ahead and keep things running smoothly, which makes a huge difference for the team and for the animals we care for.”

Plant Engineer at Georgia Aquarium

4 critical failures

caught in the first 3 weeks

“For the first time, we can clearly see what’s happening on the floor before a failure hits. That kind of visibility is a game-changer.”

Trevor Baker

Sr. Manager, Manufacturing Strategic Initiatives

FAQ