REMOTE CONDITION MONITORING

Machine Failure Detection,

Powered by AI

From continuous monitoring to guided resolution: detect faults, see the evidence, and close the loop with verified repairs.

Machine Failure Detection,

Powered by AI

From continuous monitoring to guided resolution: detect faults, see the evidence, and close the loop with verified repairs.

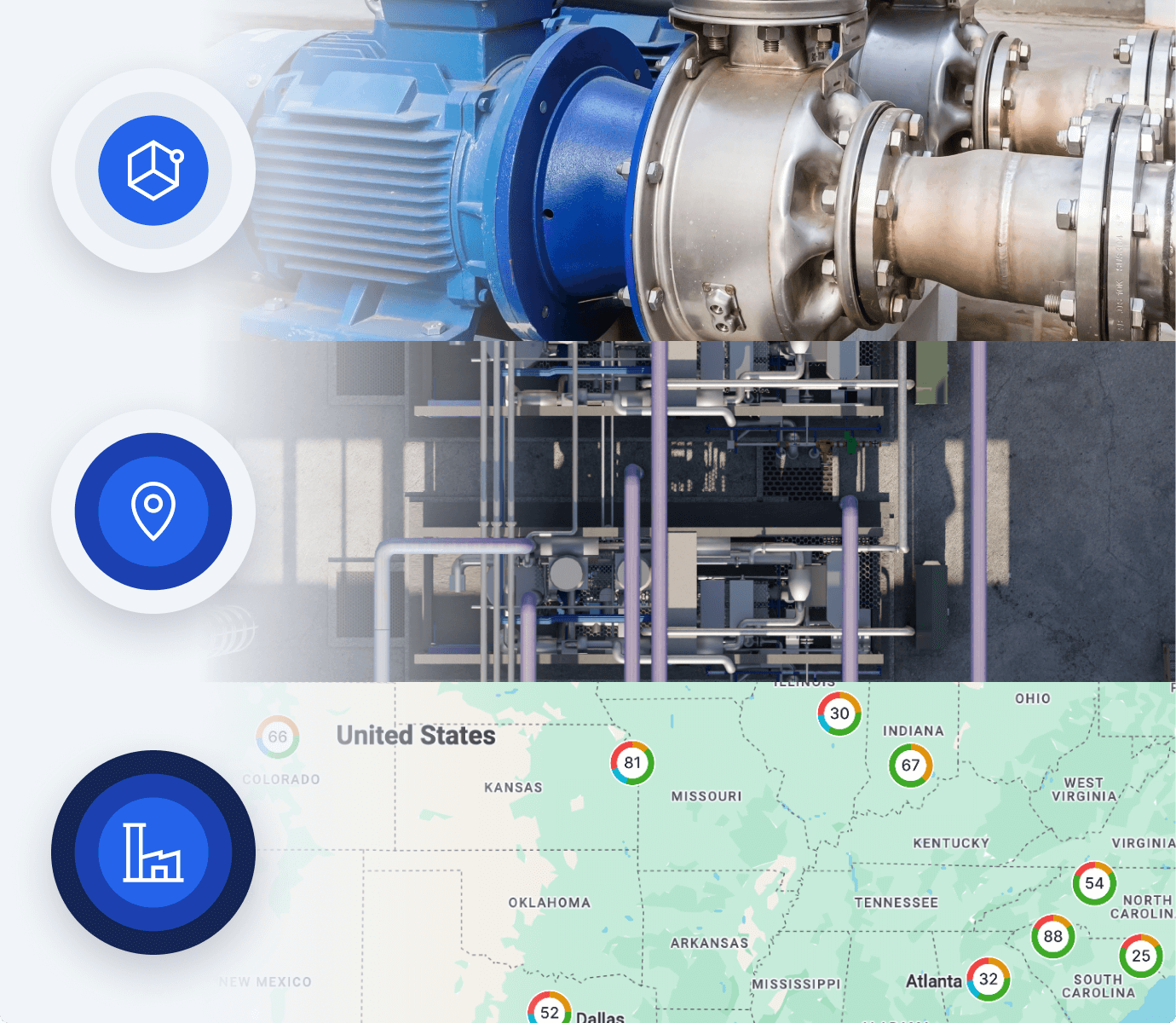

Sample & Detect

Sensors stream real-time vibration, temperature, runtime, and RPM. AI maps the signal patterns to specific failure modes (e.g., bearing wear, misalignment, unbalance).

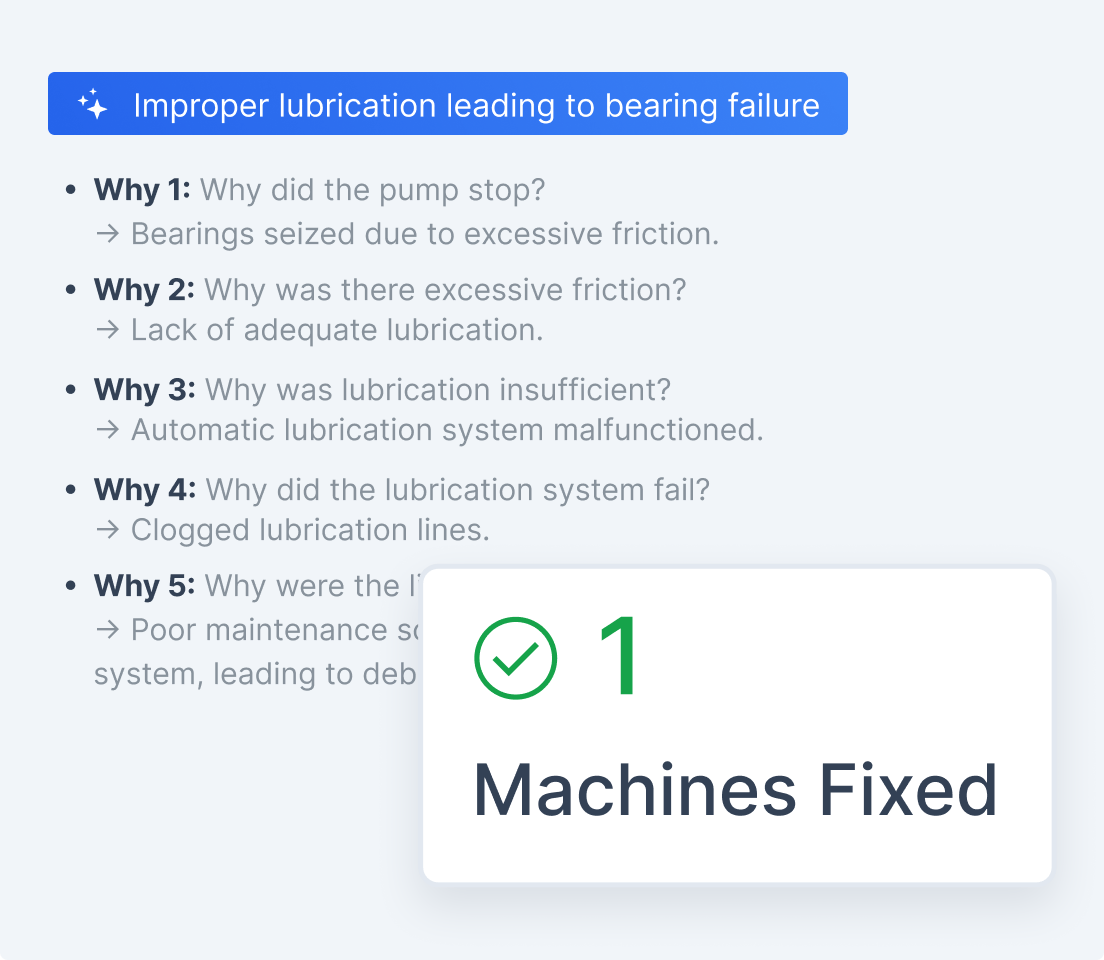

Diagnose with Context

Your data is benchmarked against millions of historical machine hours and bearing libraries to make an accurate, explainable call - complete with evidence.

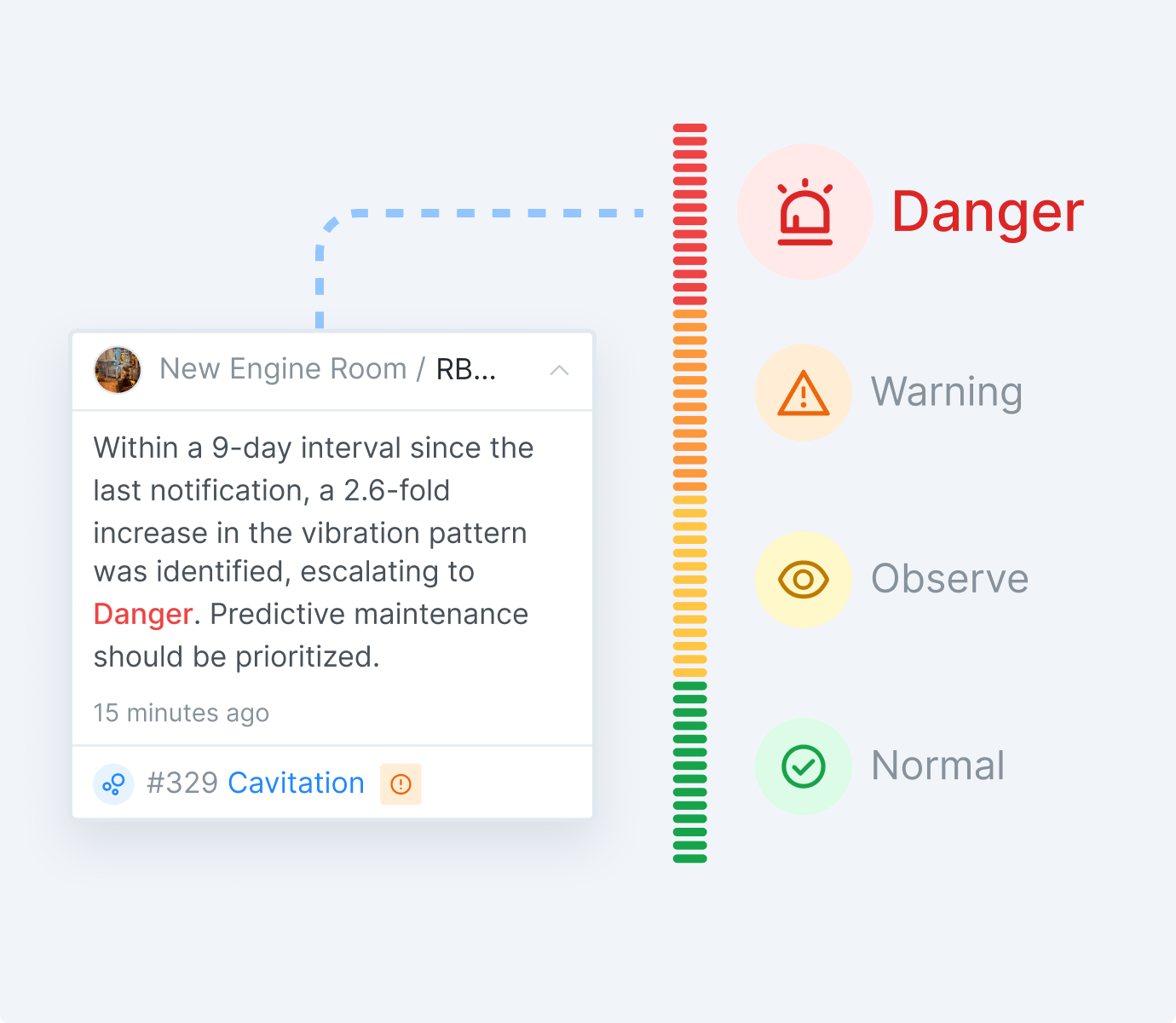

Prioritize What Matters

Alerts are ranked by failure severity and asset criticality, so mission-critical machines rise to the top while low-impact noise stays out of the way.

Notify & Act

You get an alert that spells out the root cause and next steps - the only thing left to do is the fix.

Bearing Erosion

Bearing Wear

Belt Wear

Blade Passage

Overvoltage

Overload

Operational Problems

Phase Unbalance

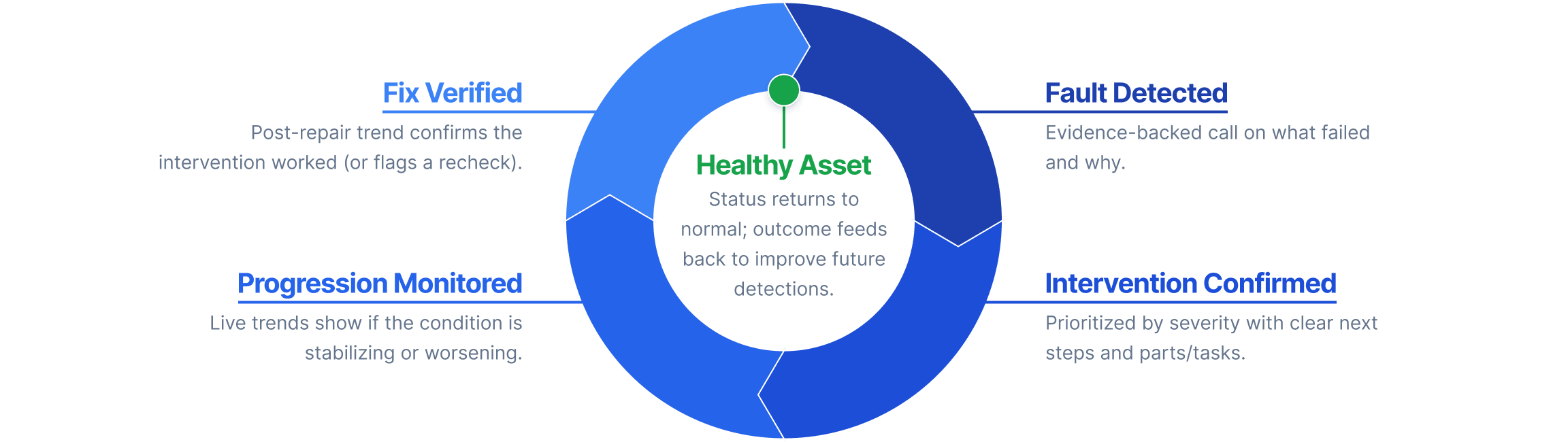

FAILURE LIFECYCLE MANAGEMENT

From alert to verified fix to a healthy asset - Tractian drives the whole cycle.

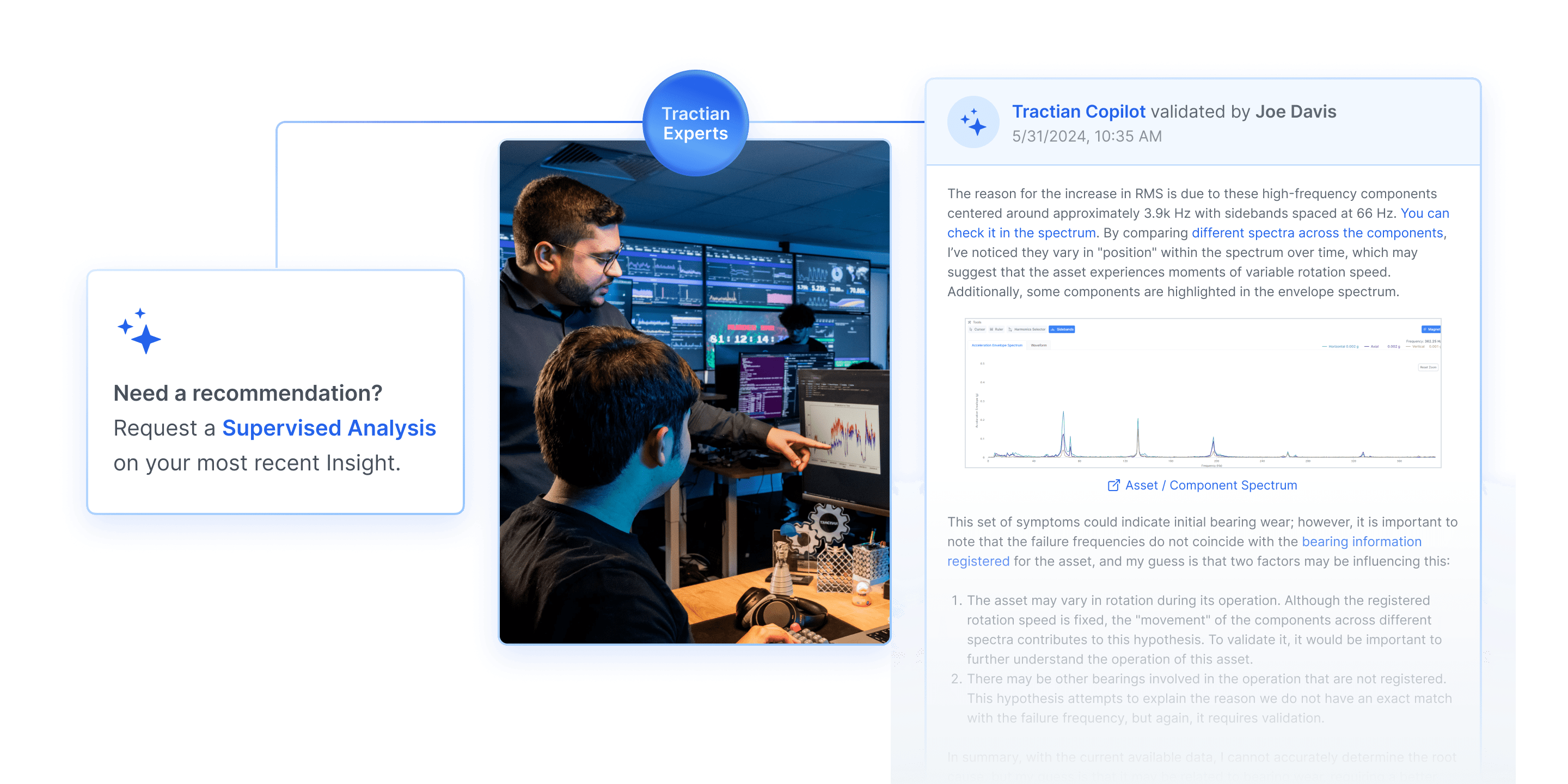

EXPERT VALIDATION WHEN IT COUNTS

Not every alert needs a manual review - but when it does, our supervised analysis feature connects you with expert-vetted insights. Ideal for non-vibration experts or teams validating high-impact alerts.

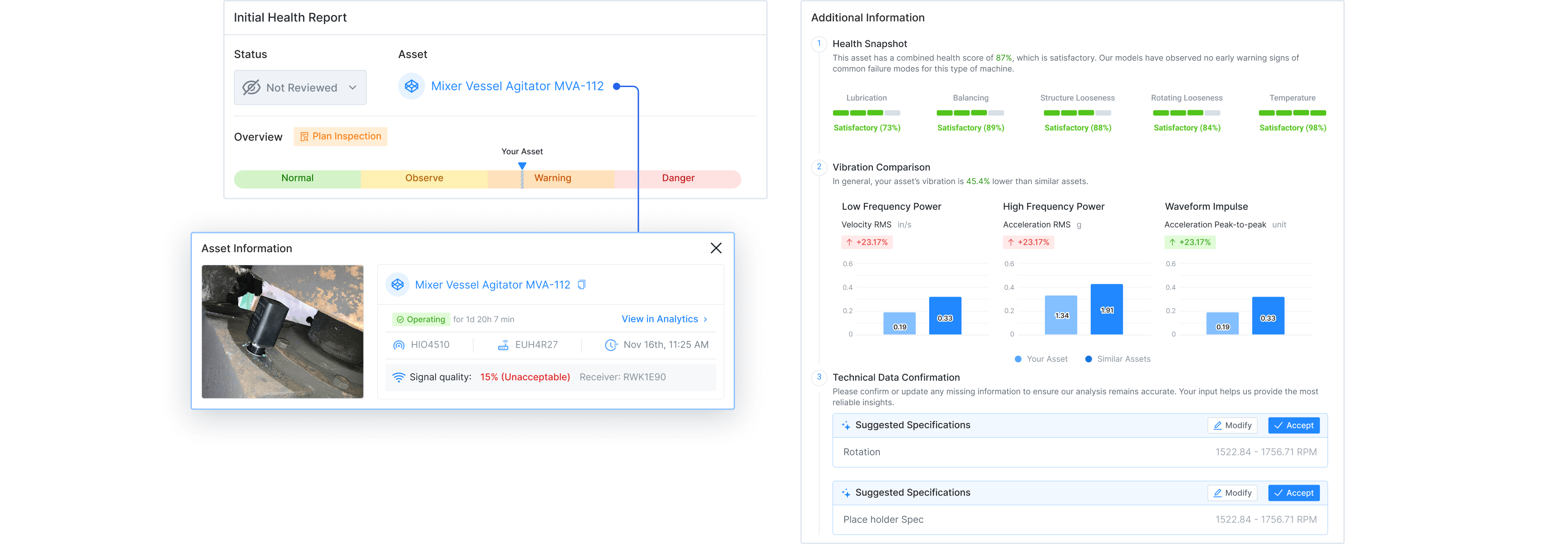

INITIAL HEALTH REPORT

Soon after installation, you get a baseline report on machine health with failure-mode assessment and vibration spectrum benchmarked against our global dataset. If the asset is healthy, it stays quiet; if not, you’re notified right away and start catching failures from day one.

CASE STUDIES

Teams use Tractian Condition Monitoring to catch faults early, cut downtime, and prove the fix - at scale.

$1.0M

in production savings

168 hours

of avoided downtime

“There were some issues that I would say, if not for having Tractian, we would have never noticed… It was pretty impressive for that, the results we got early on.”

Jacob Hoffine

Reliability Engineer

24/7 monitoring

increased operational reliability

“Tractian has allowed us to move from firefighting mode to proactive maintenance. We can plan ahead and keep things running smoothly, which makes a huge difference for the team and for the animals we care for.”

Plant Engineer at Georgia Aquarium

4 critical failures

caught in the first 3 weeks

“For the first time, we can clearly see what’s happening on the floor before a failure hits. That kind of visibility is a game-changer.”

Trevor Baker

Sr. Manager, Manufacturing Strategic Initiatives