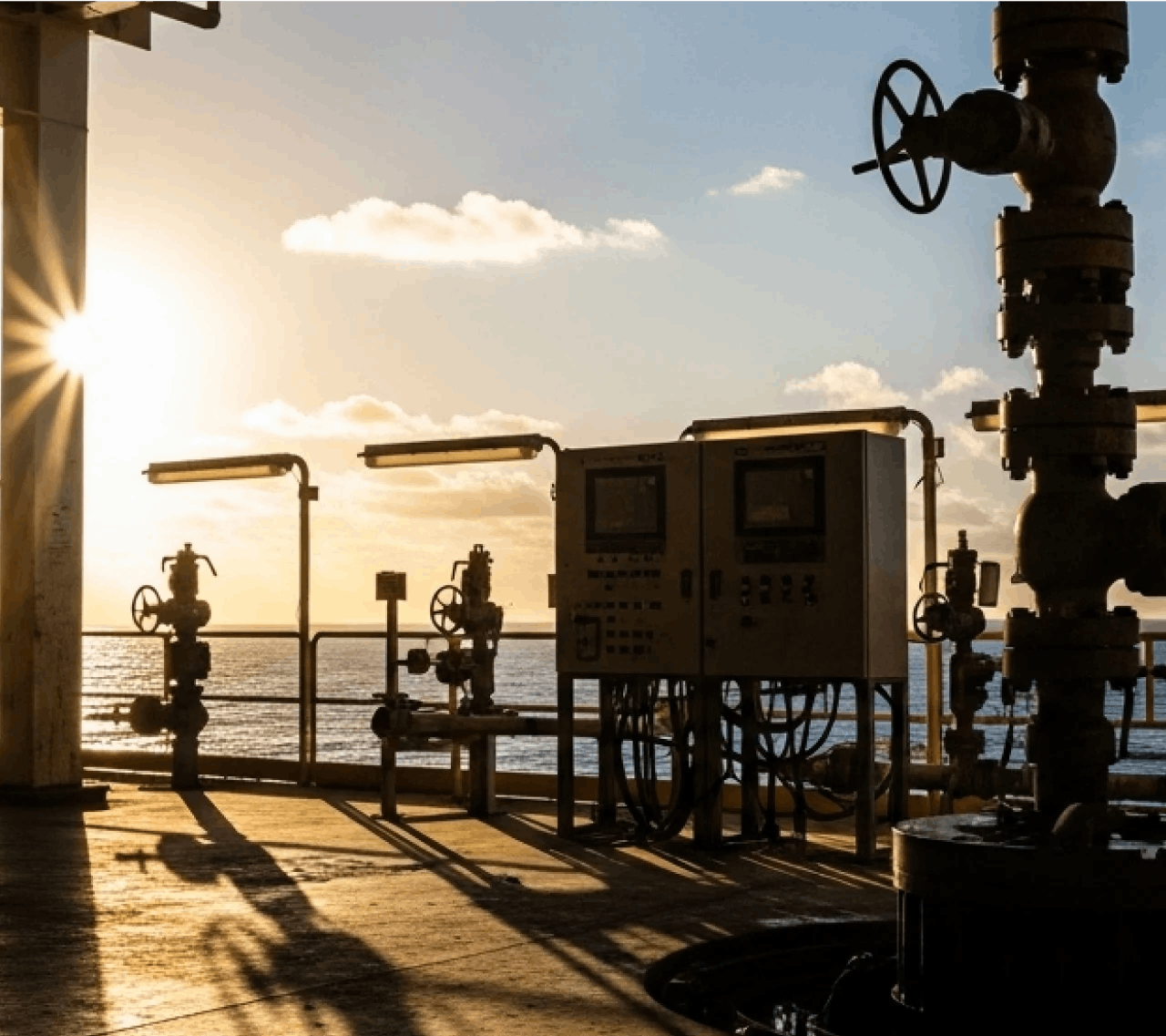

OIL & GAS CMMS AND CONDITION MONITORING SENSORS

Reliability Isn’t Optional in Oil & Gas

From pipelines to pumps, Tractian gives oil & gas operators real-time condition monitoring, automated maintenance workflows, and AI-powered alerts to prevent failures, reduce risk, and keep production running safely.