DOWNTIME PREVENTION & REPORTING

Decrease Downtime,

One Failure at a Time

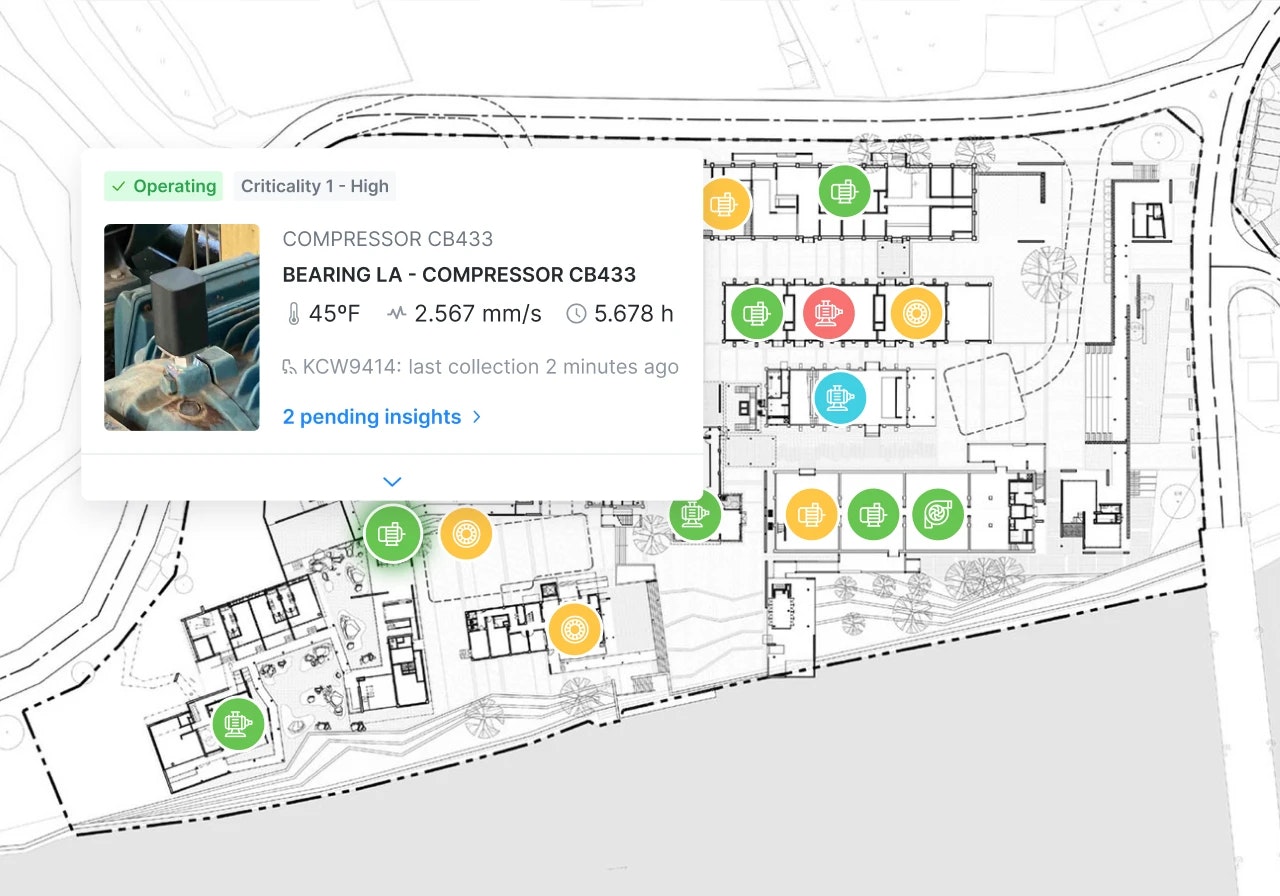

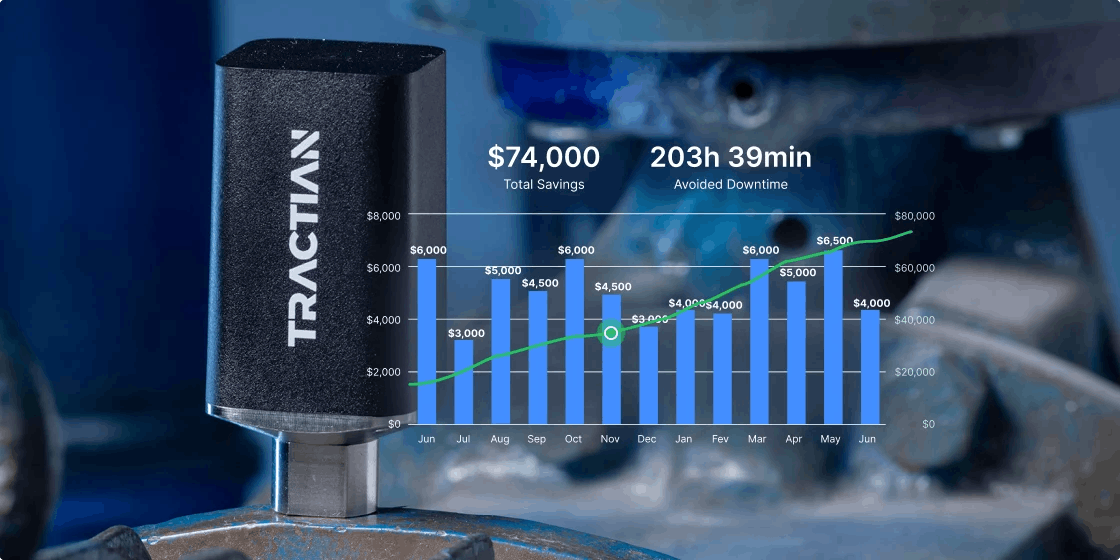

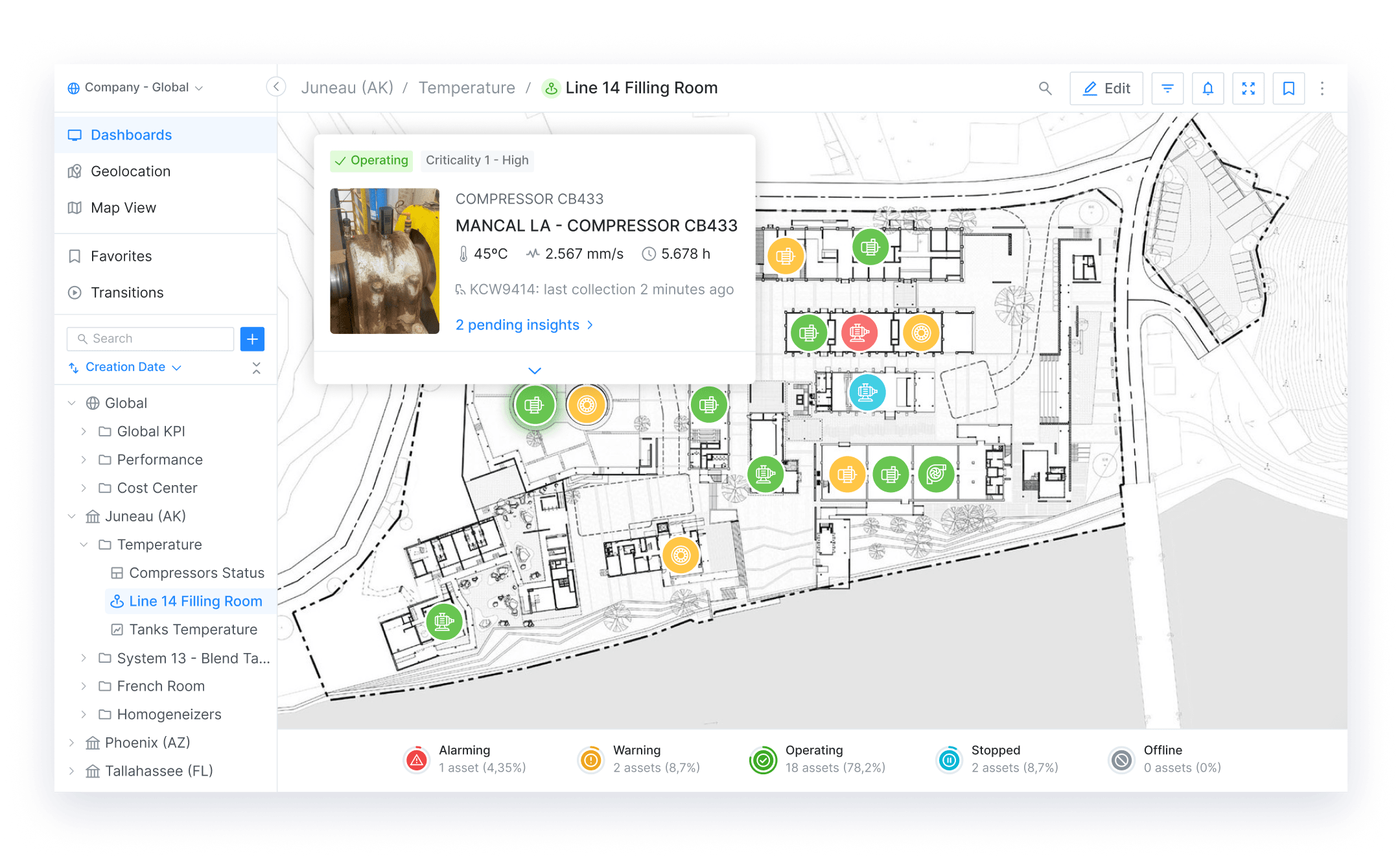

Live floorplans show machine health across the plant, while condition monitoring reports turn alerts and fixes into executive-ready metrics - downtime avoided, savings, MTBF, and ROI.