Why Tractian OEE?

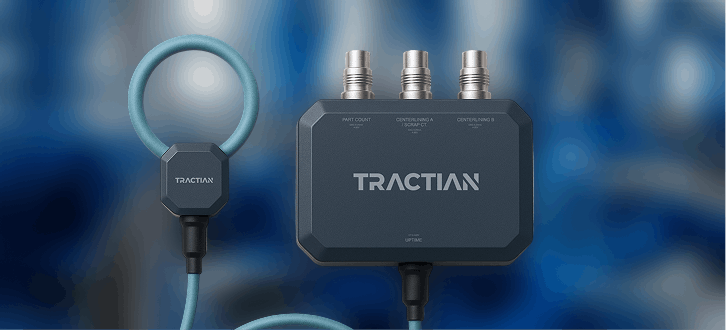

Best-in-class sensors ensure your data is accurate and reliable

Quick to deploy and easy to scale.

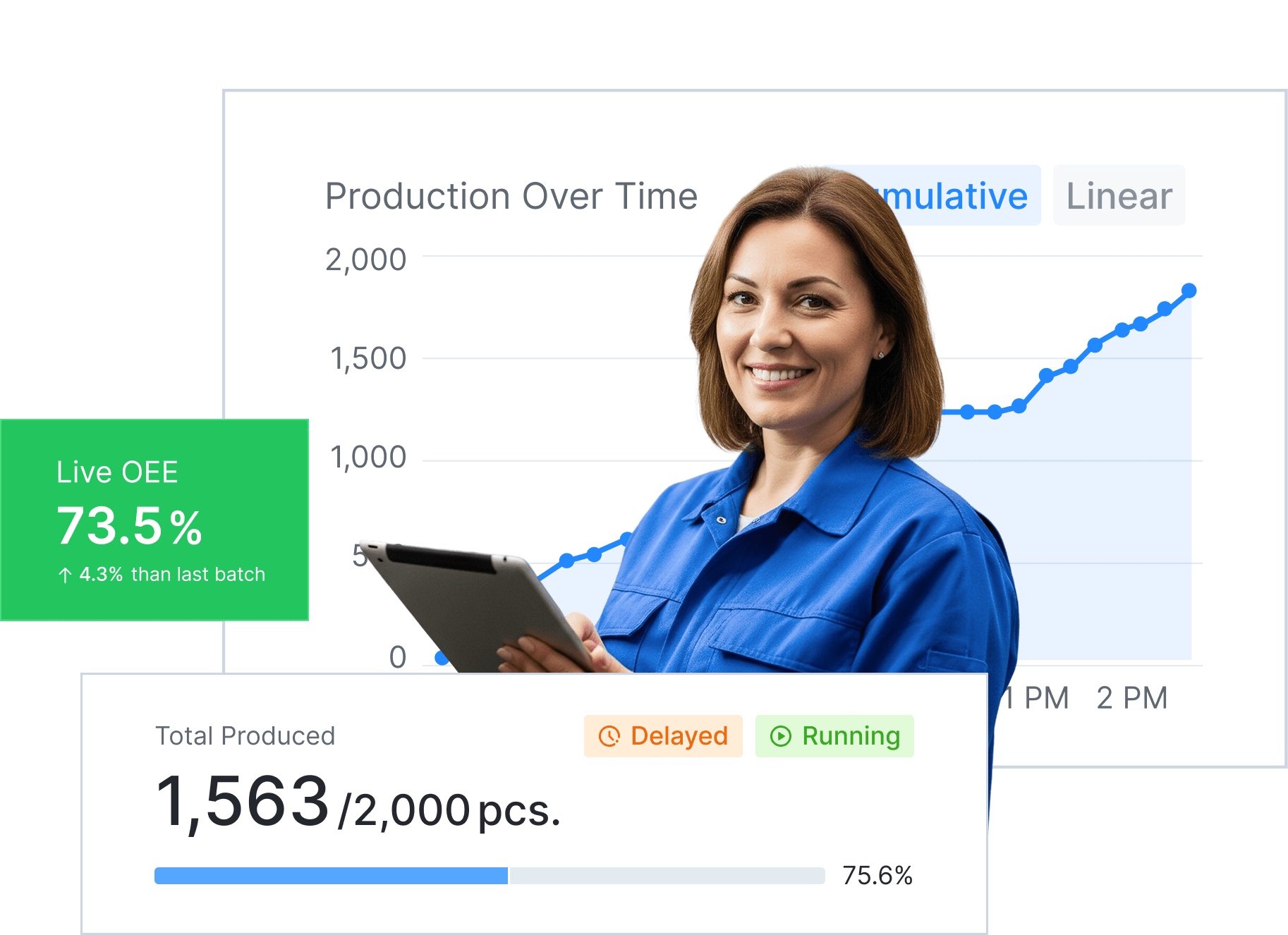

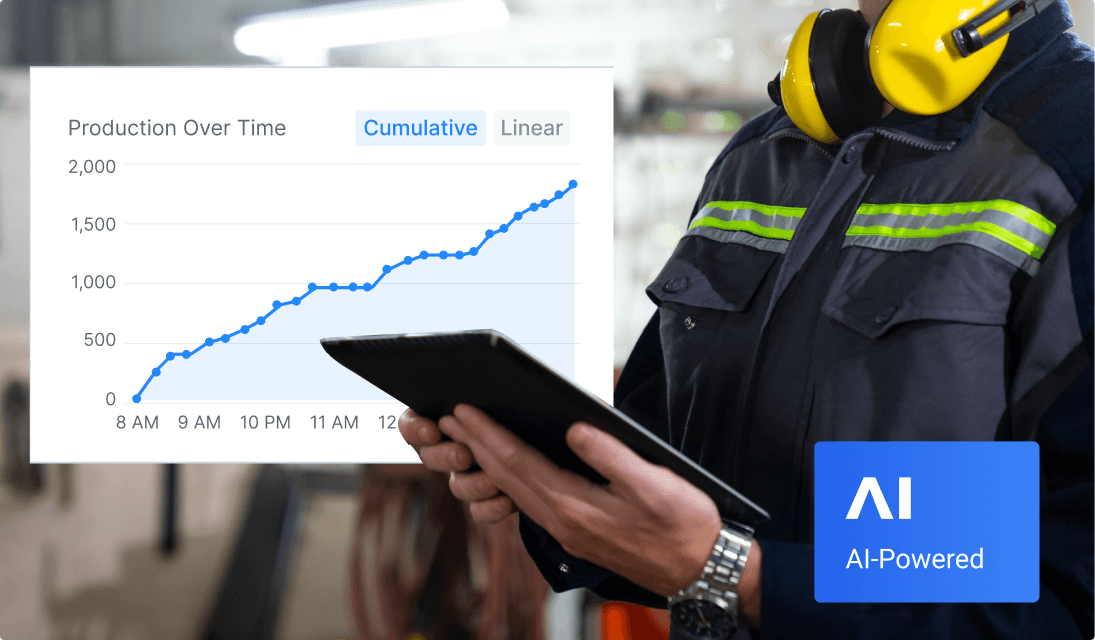

Introducing Tractian OEE, a solution for process and production monitoring solution, designed to redefine industrial efficiency.

Smart sensors and operator-ready platform to keep production on track.

Put the power of your data into the hands of your frontline team.

Use the shop floor instant communication channel, Factory Chat™, to keep conversations where the work happens, so your team can troubleshoot, share updates, and act on OEE insights, all from the same system.

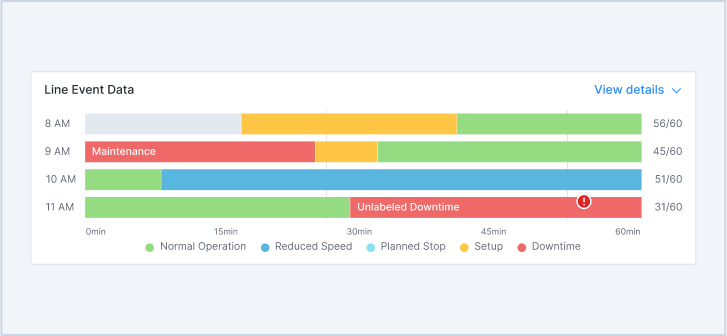

Enable operators to log downtime reasons from the shop floor. Tractian AI learns patterns and context to automatically suggest the most likely causes - making labeling faster, smarter, and more accurate every shift.

Why Tractian OEE?

Quick to deploy and easy to scale.

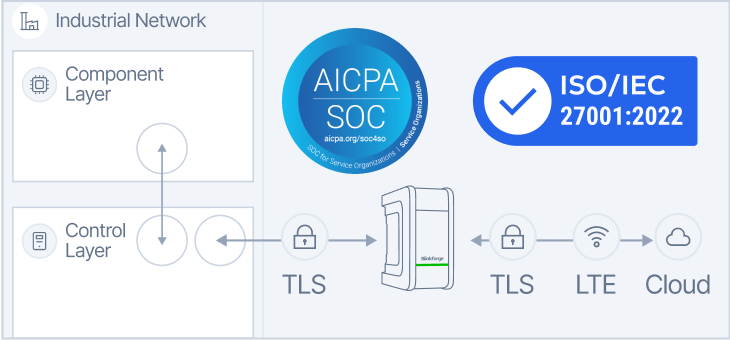

Connect to all your machines with industrial-grade proprietary IoT sensors that can tap into analog and digital inputs, current readings, and PLCs ensuring full compatibility with your systems.

Fast installation with our easy clip-on IoT sensors. Built for security, reliability, and continuous uptime, our hardware is backed by SOC 2 Type II and ISO 27001 certifications.

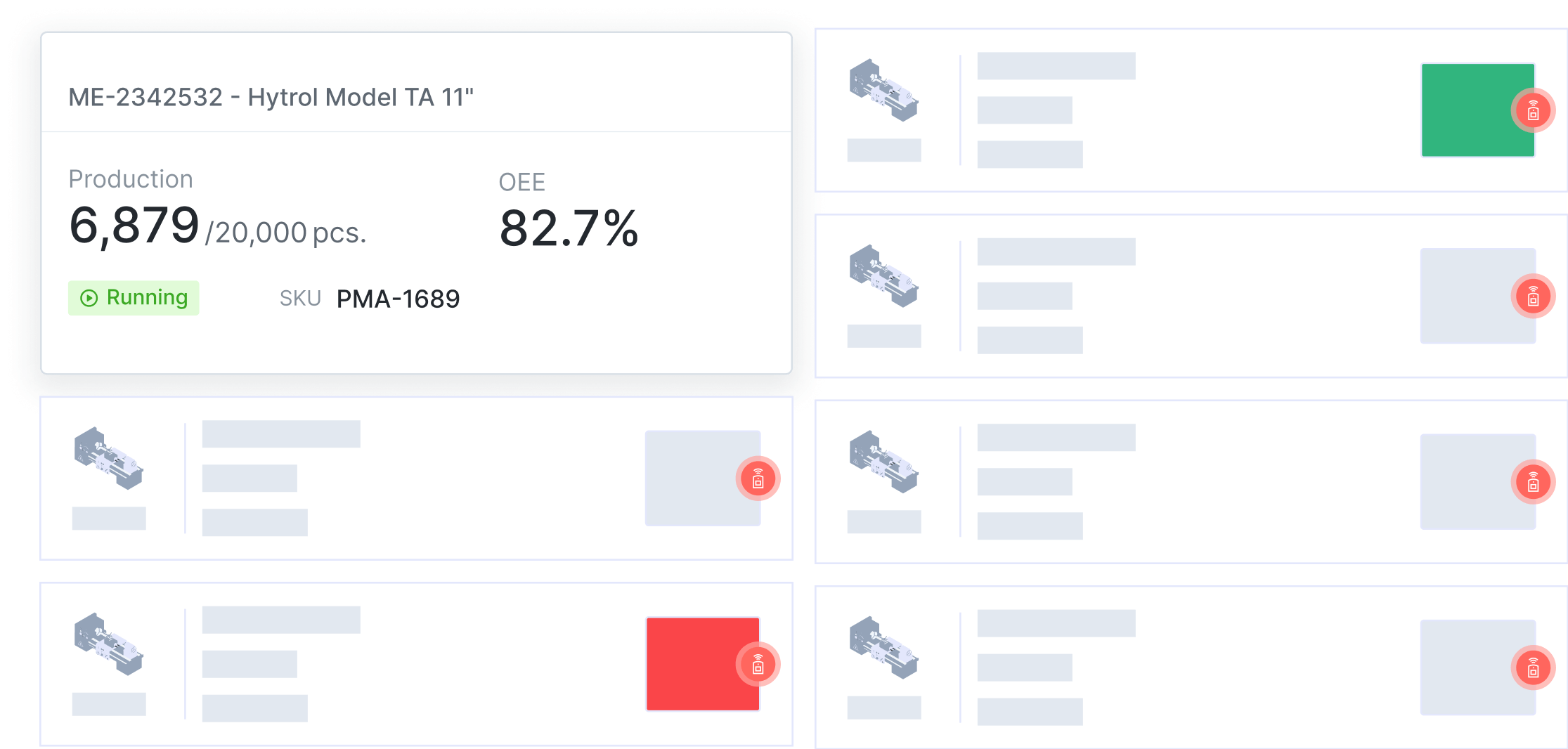

Utilize real-time analytics to monitor the status of your machines, track OEE, identify downtime causes, and discover hidden inefficiencies. Gain site-wide visibility at your fingertips.

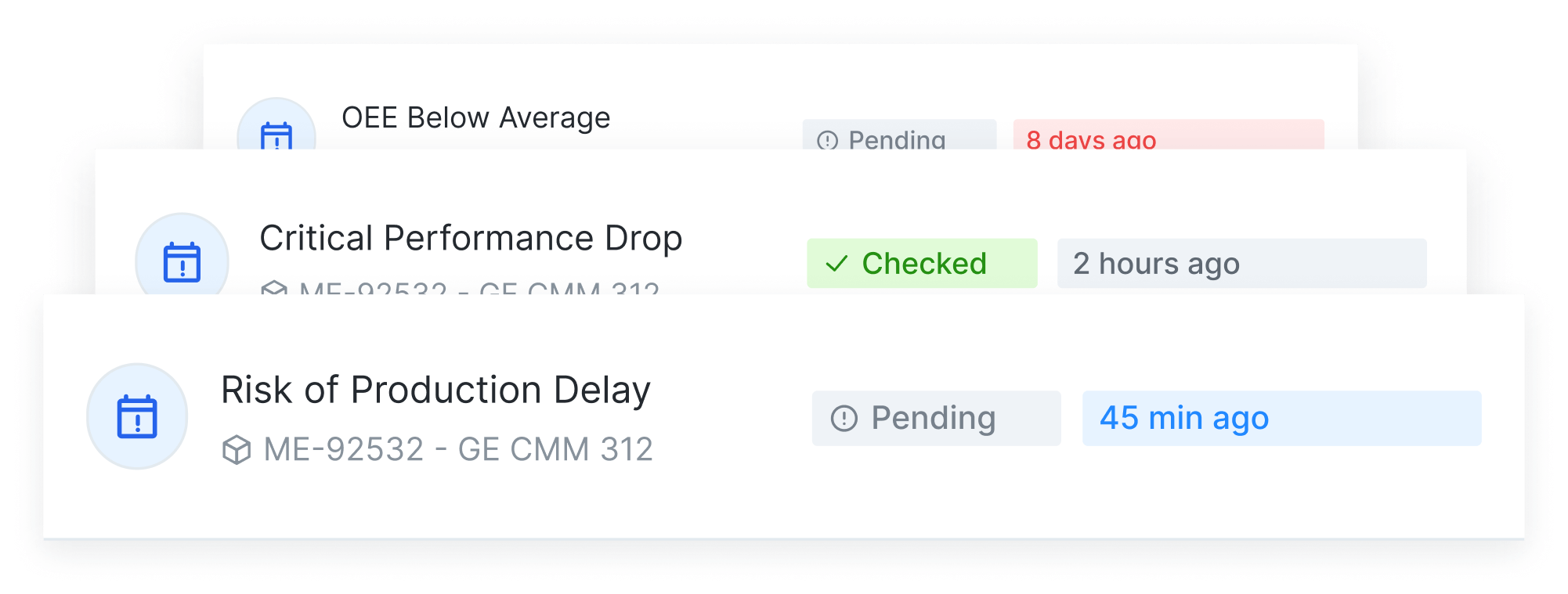

Fix the right problem, at the right time. Instantly flag inefficiencies, notify the right teams, and resolve bottlenecks before they impact output

Track OEE at a glance, spot trends, and take immediate action - all in a single system.

Our AI delivers the critical insights you need to stay ahead. Proactively identify the right problems, flag inefficiencies, and resolve bottlenecks using powerful predictive insights before they impact output. Instantly understand OEE, spot emerging trends, and take decisive action, all guided by intelligent data within one system.

FAQ

Chat with one of our OEE experts for a quick walkthrough of the platform and insights tailored to your operation.