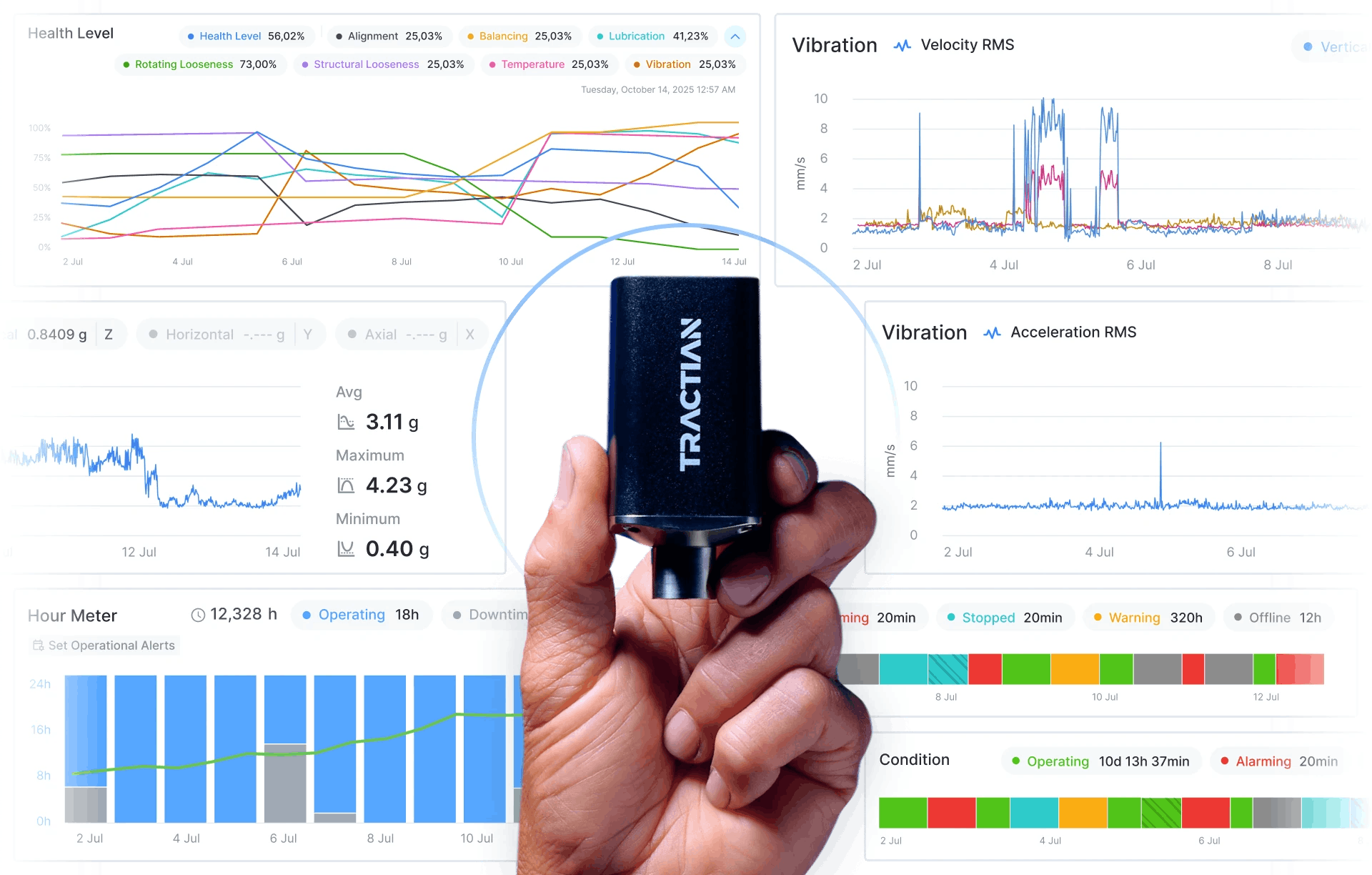

REAL-TIME VIBRATION ANALYSIS

Your Vibration Analysis Workspace

Tractian gives you the visibility and tools to diagnose failure modes in real time - remotely and reliably.

Your Vibration Analysis Workspace

Tractian gives you the visibility and tools to diagnose failure modes in real time - remotely and reliably.

A TRUE VIBRATION WORKSPACE

DESIGNED FOR EXPERTS. CLEAR FOR EVERYONE

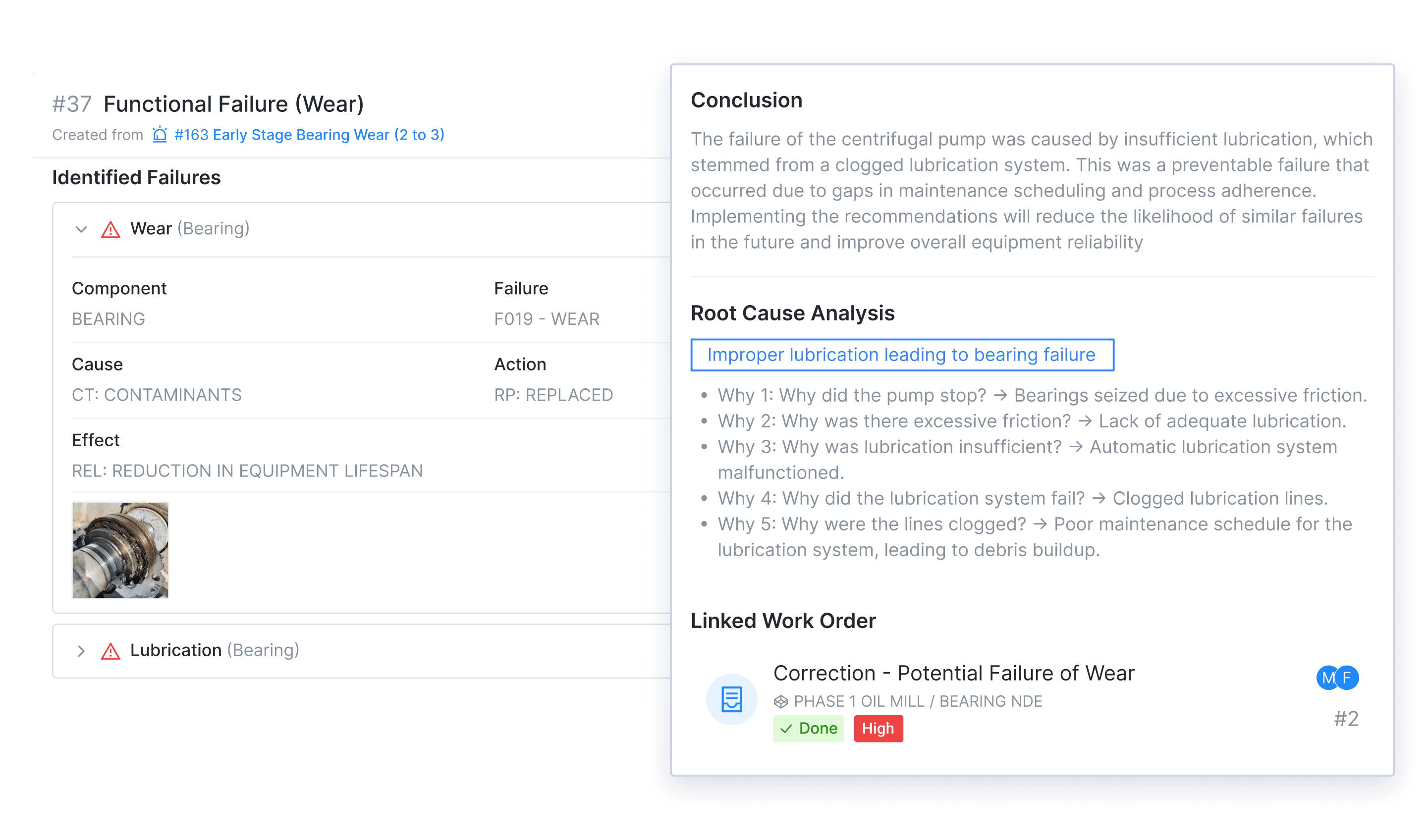

Tractian AI pinpoints root causes automatically using vibration signatures.

These insights are validated against historical failures, frequency libraries, and expert -reviewed data, giving your team the confidence to move faster and focus their attention where it matters most.

Bearing Erosion

Bearing Wear

Belt Wear

Blade Passage

Overvoltage

Overload

Operational Problems

Phase Unbalance

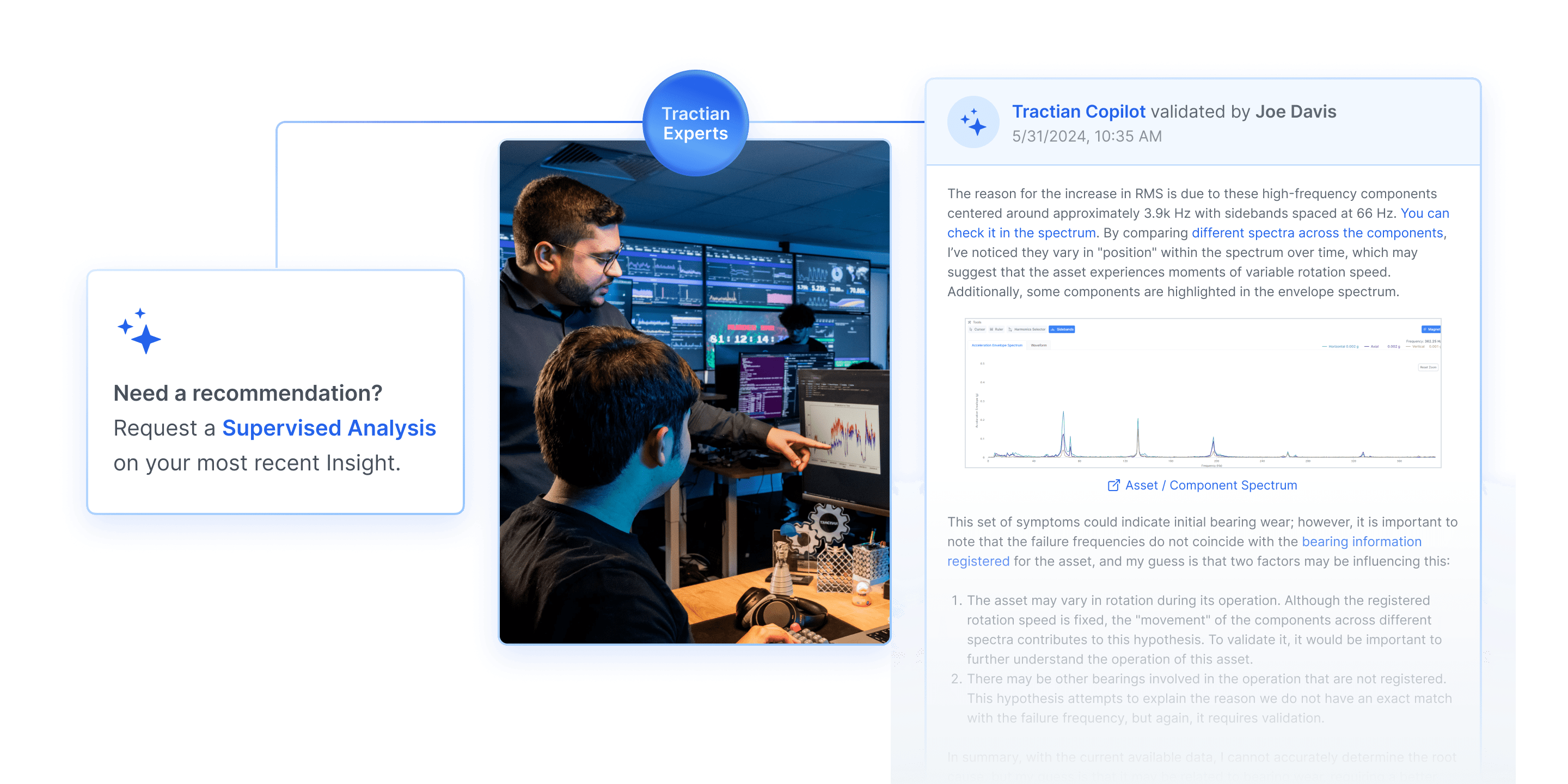

EXPERT VALIDATION WHEN IT COUNTS

Not every alert needs a manual review - but when it does, our supervised analysis feature connects you with expert-vetted insights. Ideal for non-vibration experts or teams validating high-impact alerts.

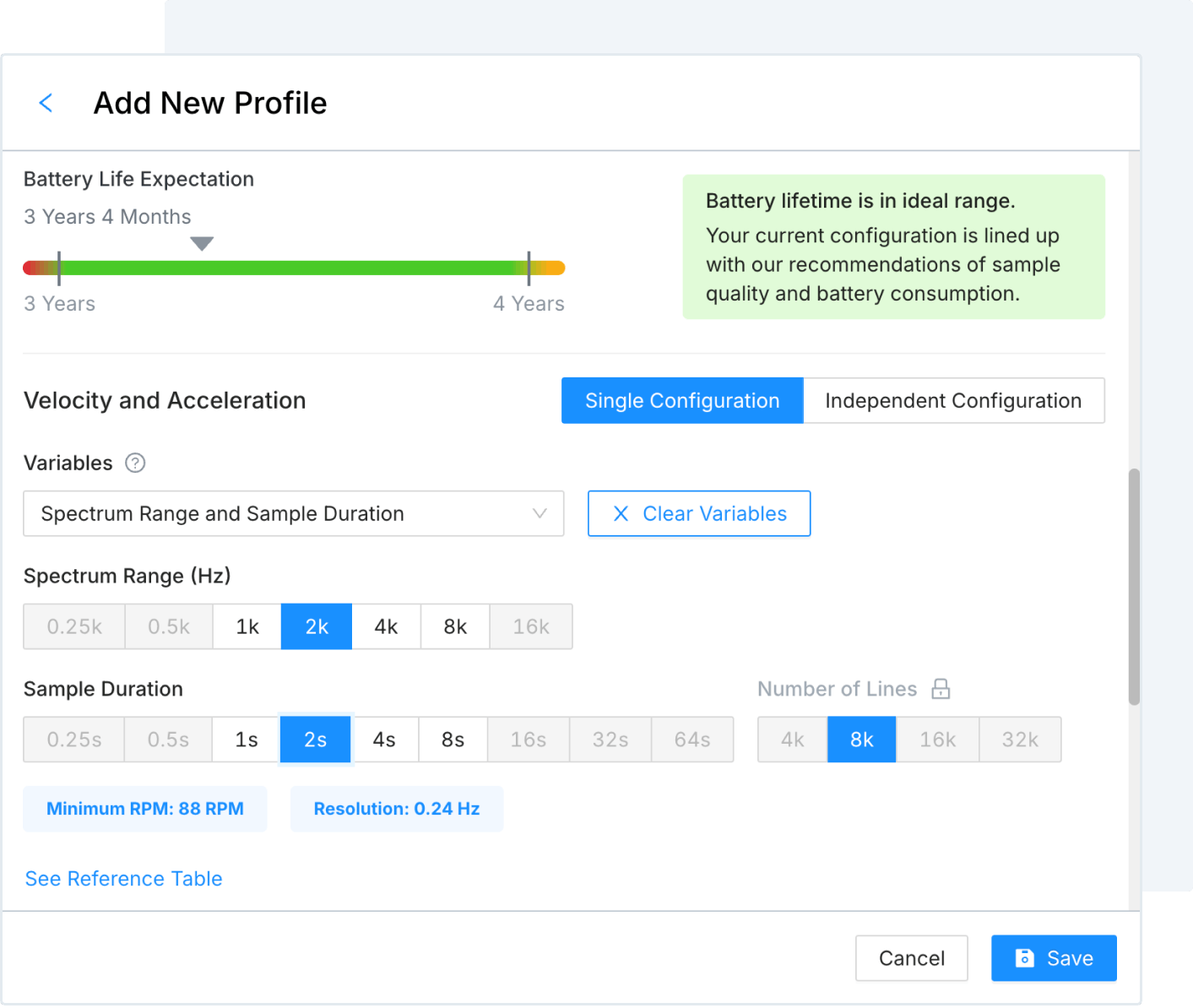

Set up specific data samples to extract key information from different assets.

Auto Diagnosis™ Sample

Automatic, AI-powered sampling every 30 minutes. Record vibration, acceleration, and envelope acceleration to identify faults with precision, adapting to asset behavior for continuous monitoring without manual intervention.

Trend Sample

For short-interval monitoring, this mode samples velocity and acceleration data such as RMS, Peak-to-Peak, and Crest Factor. Ideal for identifying patterns and efficiently planning preventive maintenance.

Expert Sample

Provides full autonomy in adjusting parameters such as sample duration and resolution, spectrum interval, and number of lines, offering flexibility for in-depth, on-demand diagnostics with uncompressed data.

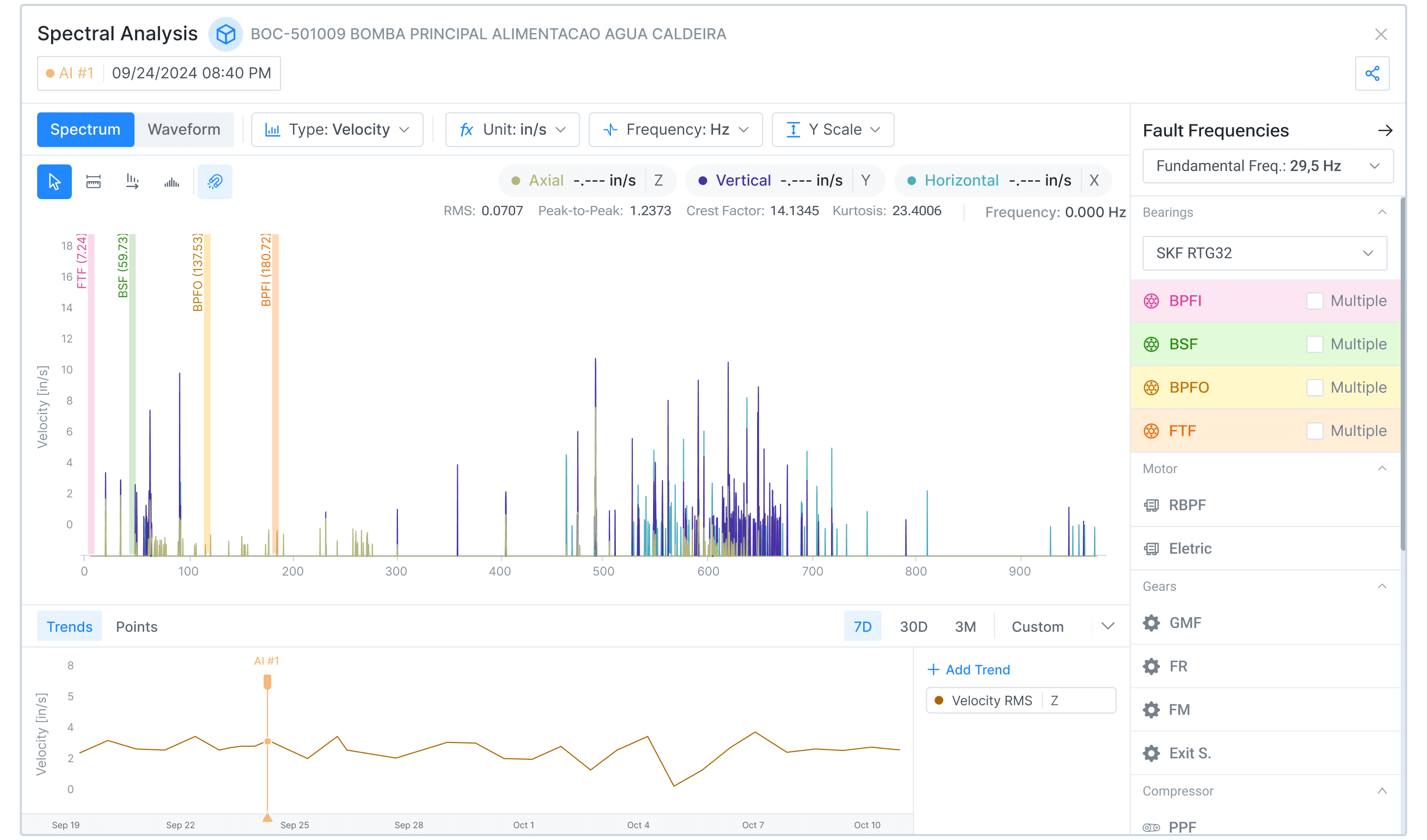

The Spectral Analysis tool allows you to identify issues in your machinery and detect fault frequencies such as BPFI, BPFO, and GMF.

Cursor

An essential tool for highlighting specific points in the spectrum, such as frequencies or amplitudes.

Ruler

Calculates the distance between points in the spectrum, like the distance between a fundamental frequency and its harmonics.

Harmonics Selector

Helps identify harmonic frequencies or multiples of a fundamental frequency.

Sidebands

Identifies peaks around a primary frequency, typically resulting from modulation.

Frequency Range

Up to 16kHz

Number of Lines

Up to 32k

Acquisition Frequency

Up to 32kHz

Resolution

Down to 0.01 Hz

FAQ

Ready to See It in Action?