The chemical industry had a direct impact on the transformation of our economy in the past century – and maintenance has helped optimize production processes in the sector.

These procedures can be highly profitable when the right industrial chemical processes are in place, as well as the right chemical industry maintenance program.

In this article, we’ll share how to optimize maintenance processes in the chemical industry.

Main Parts of the Chemical Industry

The chemical industry is so large that it’s divided into 2:

- Basic chemical industry: the sector that deals with the production of primary chemicals, such as petrochemicals, basic inorganic chemicals, and basic organic chemicals, which are used as building blocks for various other chemical products and processes.

- Chemical processing industry: focuses on transforming basic chemicals and raw materials into more specialized products through various chemical processes and reactions. This sector includes activities such as refining, blending, mixing, and formulating chemicals for specific applications.

In recent years, there has been a lot of talk about the fine chemicals industry, which creates very specific products, such as biotechnology. However, it is not yet considered a fundamental pillar of this industry, as the other two are.

The basic chemical industry is the production line responsible for using resources in their natural state and transforming them into intermediate products. These are usually chemical substances in their purest state and serve as raw materials for other industries. For example, petrochemicals as mentioned above, with products derived from oil, and metallurgy.

The chemical processing industry is basically chemical manufacturing. It uses the products created by the basic chemical industry and is responsible for manufacturing other products, such as everyday chemicals – for example, the pharmaceutical industry or the plastics industry.

Lean Manufacturing in Maintenance: How to Reduce Waste

Chemical Sector Segments

There are several segments that derive from the 2 main sectors in the chemical industry. These can include the manufacture of petrochemicals, pharmaceuticals, basic chemicals, specific chemicals, plastics and polymers, among others.

Industrial Chemical Processes

The chemical industry involves a variety of processes to produce and transform substances. These processes can include:

- Chemical Reactions: Chemical industrial plants transform substances through reactions such as synthesis, decomposition, substitution and oxidation-reduction. Reactants are combined to form the desired chemical products by manipulating conditions of temperature, pressure and catalysts.

- Distillation: Separation process based on the boiling points of the components of a liquid mixture. In industrial chemical plants, it’s used to purify liquids, separate mixtures and recover solvents.

- Crystallization: A process by which crystalline solids are formed from a super-saturated solution. It is used to purify solids, produce high-purity materials, and separate components from a solution.

- Extraction: Involves separating components from a mixture using solvents. In the chemical industry, it is used to separate substances of interest from raw materials or intermediate products.

- Organic and Inorganic Synthesis: Organic synthesis refers to the creation of organic compounds from simpler molecules. Inorganic synthesis involves the formation of inorganic compounds. Both syntheses are essential in the production of various chemical products, such as pharmaceuticals.

- Polymerization: Small molecular units called monomers combine to form longer chains known as polymers. Polymers are used in a wide range of products, from plastics to textile fibers.

Work Orders: The Complete Guide

Types of Machinery and Equipment

In the chemical sector, industrial plants usually have a variety of assets used in the manufacturing process. These can include processing equipment, chemical reactors, distillation towers, storage tanks, process control systems, separation and purification units, among others.

Most Common Failures in the Chemical Industry

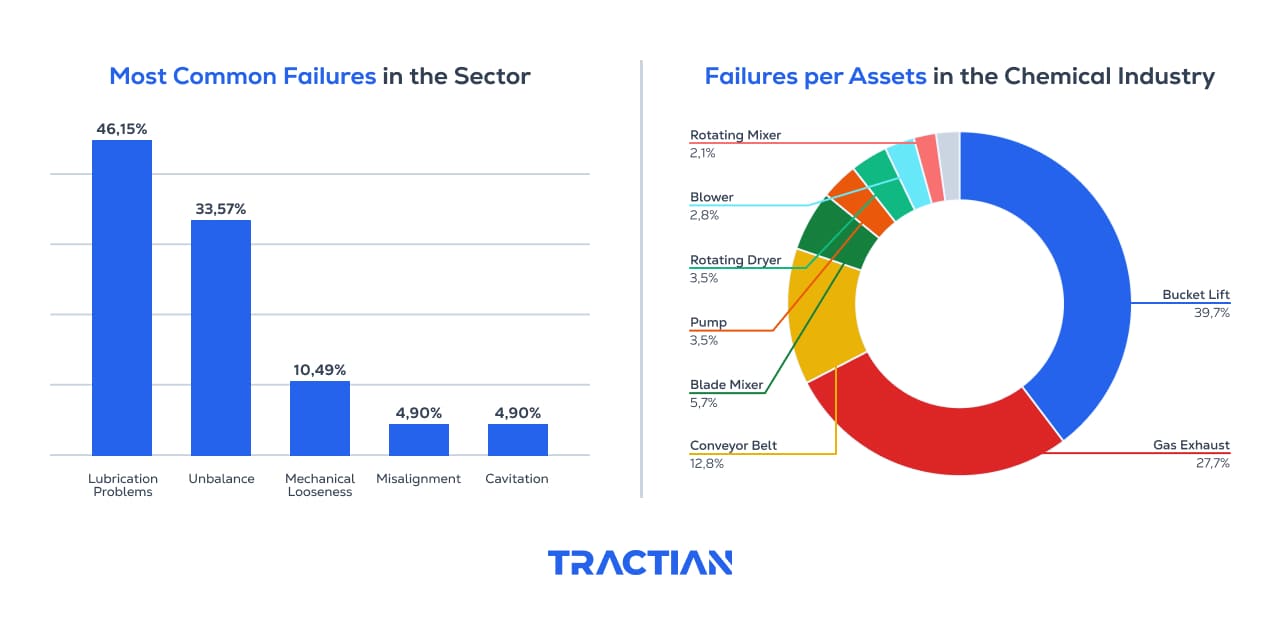

Equipment failures within the chemical industry, due to their critical nature, can result in unplanned downtime with high maintenance costs, reduced production and safety, and environmental problems. In operations where precision and reliability are paramount, it is essential to address and prevent the causes that can lead to asset failure.

Learn more about some of the main failure modes in the chemical industry:

- Inadequate Lubrication: Within the chemical industry, where often corrosive and dangerous substances are handled, proper lubrication of equipment is essential. Lack of lubrication or incorrect lubrication can accelerate corrosion and wear, putting the safety and efficiency of processes at risk.

- Unbalance: Equipment such as centrifuges and agitators, operate at high speeds and must maintain a precise balance to avoid irregular vibrations. Unbalance can affect not only the integrity of the equipment, but also the quality of the chemicals produced and the safety of workers.

- Mechanical Looseness: Chemical processes require high precision and consistency, so any kind of mechanical looseness can result in unwanted fluctuations in products. Furthermore, in environments with toxic or flammable substances, looseness can increase the risk of dangerous leaks.

- Misalignment: Can cause friction and excessive wear on crucial parts, affecting the integrity of chemical products and processes. In this industry, where even small deviations can have a significant impact on quality, precise alignment is essential.

- Cavitation: In chemical pumping systems, cavitation can damage the internal surfaces of pumps, which can lead to contamination of the chemical or loss of the desired mixture. Pump efficiency is compromised, affecting production capacity and potentially resulting in off-specification products.

Early failure detection and mitigation are essential to maintaining operational integrity and maximizing efficiency. A proactive approach to maintenance work and constant monitoring are key tools for reduced downtime and ensuring trouble-free production of safe, high-quality chemicals.

Process Optimization in the Chemical Industry: ISO 55000 Standards

ISO 55000 is a set of international standards that focus on asset management. These regulations provide guidelines and best practices for managing assets and machinery.

This is essential in the chemical industry due to the nature of the substances involved in the production process.

For example, ISO 55000 is used to establish a common understanding of key concepts related to asset management and ensures that all equipment and employees involved in maintenance and asset management have an understanding of the process.

ISO 55001 is used to implement an asset management system. This involves identifying and evaluating critical assets for chemical processes, developing preventative maintenance plans and establishing KPIs to ensure compliance with safety regulations.

Chemical industries can use ISO 55002 to adapt asset management principles to their specific needs. This includes managing highly sensitive or hazardous assets, considering the specific regulations of the chemical industry and making investment decisions based on risk and asset life cycle analysis.

Maintenance Strategies for the Chemical Industry

Preventative maintenance in the chemical industry plays a key role in ensuring the safety, efficiency, continuity of operations and asset performance.

Let’s use the scheduled maintenance activities of a filtration system used in the production of chemical products as an example. By carrying out regular inspections and replacing worn components before they fail, potential problems such as cross-contamination or unplanned downtime are avoided.

As well as reducing operational risks, increasing maintenance team safety and protecting the environment, preventative maintenance in this sector helps to optimize production and keep all pieces of equipment in ideal working condition.

Types of Maintenance 101: Predictive, Preventative, Corrective Maintenance, and more

The importance of preventative maintenance, especially when paired with predictive maintenance, lies in avoiding costly problems and environmental risks, as well as improving the efficiency and reliability of chemical operations.

And by using more advanced technologies, such as condition monitoring sensors and data analysis, to continuously track equipment and predict potential failures, preventive maintenance can help to reduce the risk of problems.

Industry leaders such as Yara International maintain a reliable maintenance program with the TRACTIAN AI-assisted online monitoring technology, which relies on an extensive international database, providing several key benefits and an impressive return on investment (ROI).

Learn more about AI-assisted Maintenance

Condition monitoring, IoT sensors constantly monitor the state of equipment and send the data collected in real time to our AI platform. Yara International experienced a 7-fold increase in savings less than 3 months after the project was completed. This demonstrates a fast and significant ROI thanks to the implementation of the TRACTIAN solution, besides increased productivity.

Demystifying TRACTIAN Technology: Most Common Questions

Want to know more about automating maintenance processes in the chemical industry? Get a demo.