How to Calculate MTBF (Step by Step)

MTBF = Total Uptime / Number of Failures

This tells you the average amount of time a system or asset runs before it fails - and is key to predicting reliability.

1. Total Operating Time

The cumulative time the equipment was running properly, not just scheduled time.

2. Number of Failures

The number of complete breakdowns or unplanned shutdowns during the same period.

Example:

If your machine ran for 2,000 hours and failed 5 times:

MTBF = 2,000 ÷ 5 = 400 hours per failure

What is MTBF - and Why Does It Matter?

MTBF measures reliability. The higher the number, the better. A high MTBF means fewer breakdowns, less downtime, and more consistent production. It’s one of the clearest indicators of long-term asset performance.

What Does MTBF Include (And What It Doesn’t)?

MTBF only counts operational uptime between failures, not repair time. It focuses on how long an asset runs before needing to be fixed. For complete insight, MTBF should always be paired with MTTR.

What Causes a Low MTBF?

Low MTBF often points to recurring issues like poor maintenance routines, faulty components, or skipped inspections.

How to Improve Your MTBF

- Standardize inspection routines

- Use preventive maintenance to avoid early-stage issues

- Implement predictive tools to detect failures before they happen

- Replace parts based on condition, not just schedule

- Train teams on common root causes

When Should You Track MTBF?

Track it continuously, especially for critical assets. Use MTBF data to compare asset reliability, guide replacement decisions, and justify process improvements.

Why MTBF Works Best with MTTR + OEE

MTBF tells you how often things fail. MTTR shows how fast you fix them. OEE brings both together with performance and quality. Track all three to optimize uptime and reliability.

Why Does MTBF Matter in Maintenance Management?

Because it’s one of the clearest indicators of how reliable or fragile your operation really is. A higher MTBF means your assets are running longer without issues. That translates to more uptime, fewer emergency interventions, and lower maintenance costs.

Here’s why MTBF is crucial:

1. Boosts Equipment Availability

The longer equipment runs between failures, the more productive your operation becomes. A high MTBF means less downtime and better capacity planning.

2. Informs Better Maintenance Strategies

MTBF reveals which assets are most prone to failure. Use it to decide whether preventive, predictive, or condition-based maintenance makes the most sense.

3. Reduces Maintenance Costs

Frequent breakdowns mean more labor, parts, and production delays. By tracking and improving MTBF, you reduce emergency repairs and avoid costly downtime.

4. Supports Smarter Asset Replacement

MTBF helps justify replacement vs. repair. If an asset’s MTBF is consistently low, it may be more cost-effective to replace it than keep fixing it.

5. Improves Planning and Forecasting

Reliable MTBF data helps forecast failures - and prevent them. It allows teams to allocate resources, schedule work, and reduce surprise interruptions.

Best Practices for Improving Mean Time Between Failures (MTBF)

The key to higher MTBF is eliminating what causes repeat failures. More uptime starts with smarter maintenance strategies, better diagnostics, and stronger failure prevention.

Here’s how to improve your MTBF consistently:

1. Implement Preventive Maintenance

Fix before failure. Routine checks and part replacements reduce the risk of unexpected breakdowns.

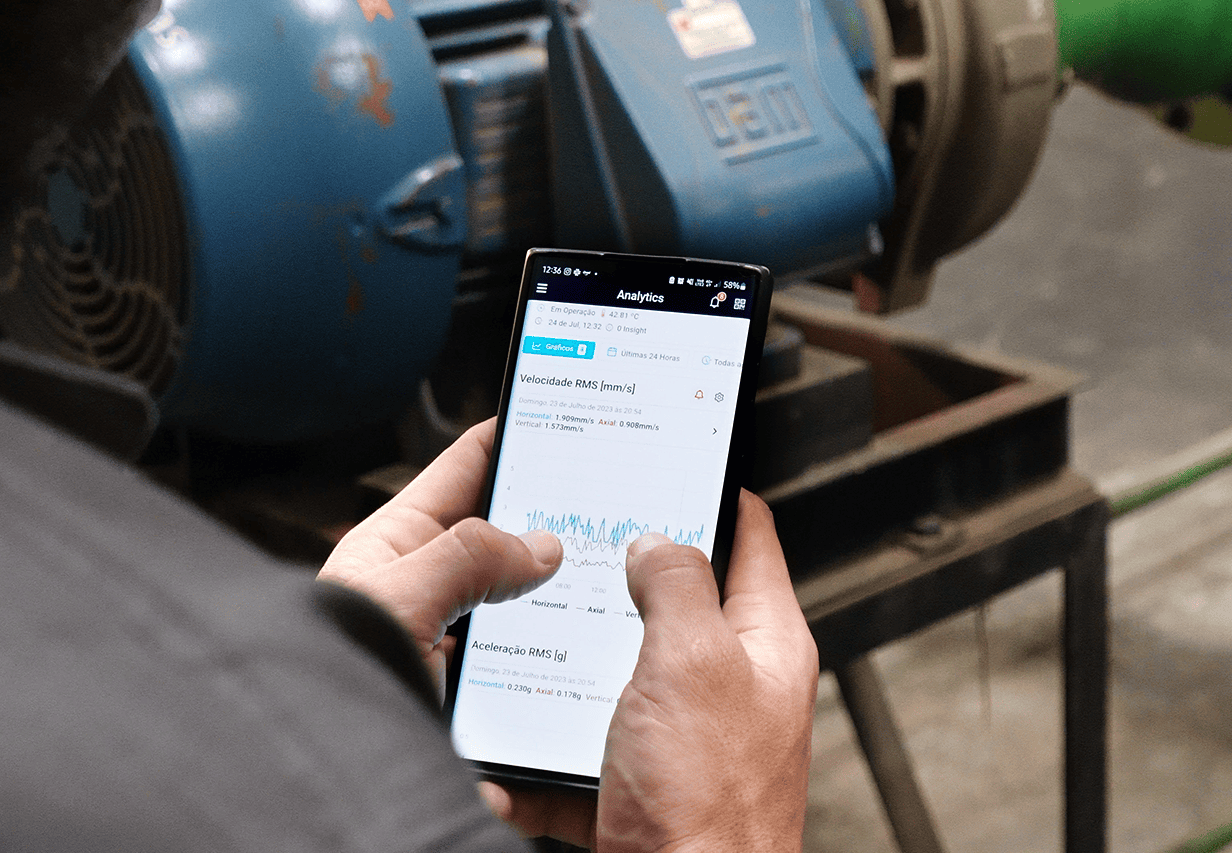

2. Adopt Predictive Maintenance

Use sensors and data to catch early warning signs. Solutions like Tractian's help identify anomalies before they turn into full equipment failures.

3. Analyze Root Causes

Don’t just fix the symptom, fix what caused it. Document every failure event and look for patterns in component wear, environmental factors, or misuse.

4. Standardize Maintenance Procedures

Consistency reduces human error. Use SOPs to ensure every technician follows the same high-quality process.

5. Track Failure History by Asset

Some machines are more failure-prone than others. Segment your MTBF data by asset type, age, and usage to focus improvement efforts.

6. Train Technicians Continuously

Ongoing training helps your team spot failure risks early and respond with precision.

See How Tractian Helps You Increase MTBF and Keep It High

Tractian tracks equipment behavior in real time, spots failure patterns, and empowers your team to fix issues before they escalate. Learn more about Tractian's CMMS.