How to Calculate MTTR (Step by Step)

MTTR = Total Downtime / Number of Repairs

This is a simple formula that calculates the average time it takes your team to bring equipment back online after a failure.

1. Total Downtime

A sum of all the time spent diagnosing, repairing, and restoring failed equipment.

2. Number of Repairs

The number of individual failure events your team handled during the period.

Example:

If your team spent 600 minutes repairing 15 failures this month:

MTTR = 600 ÷ 15 = 40 minutes per failure

What is MTTR and What is Its Importance?

MTTR measures the average time it takes to repair equipment after a failure.

It’s a key indicator of maintenance efficiency. The lower your MTTR, the faster you can return to full operation and reduce unplanned downtime.

What’s Considered in MTTR?

MTTR includes diagnosis, retrieval of parts, repair, and return to service. It reflects the entire repair cycle, not just hands-on time, and exposes weak links in your response process.

What does a High MTTR mean?

A high MTTR means slower recovery after failures occur. The results are longer downtimes and lower customer satisfaction. Reducing MTTR improves equipment availability, reduces costs, and boosts team performance, ultimately impacting every downstream touchpoint, including the customer experience.

Why Track MTTR Over Time?

Trends reveal more than averages. Tracking MTTR month by month helps you detect recurring issues, justify improvements, and make data-driven decisions.

How to Improve Your MTTR

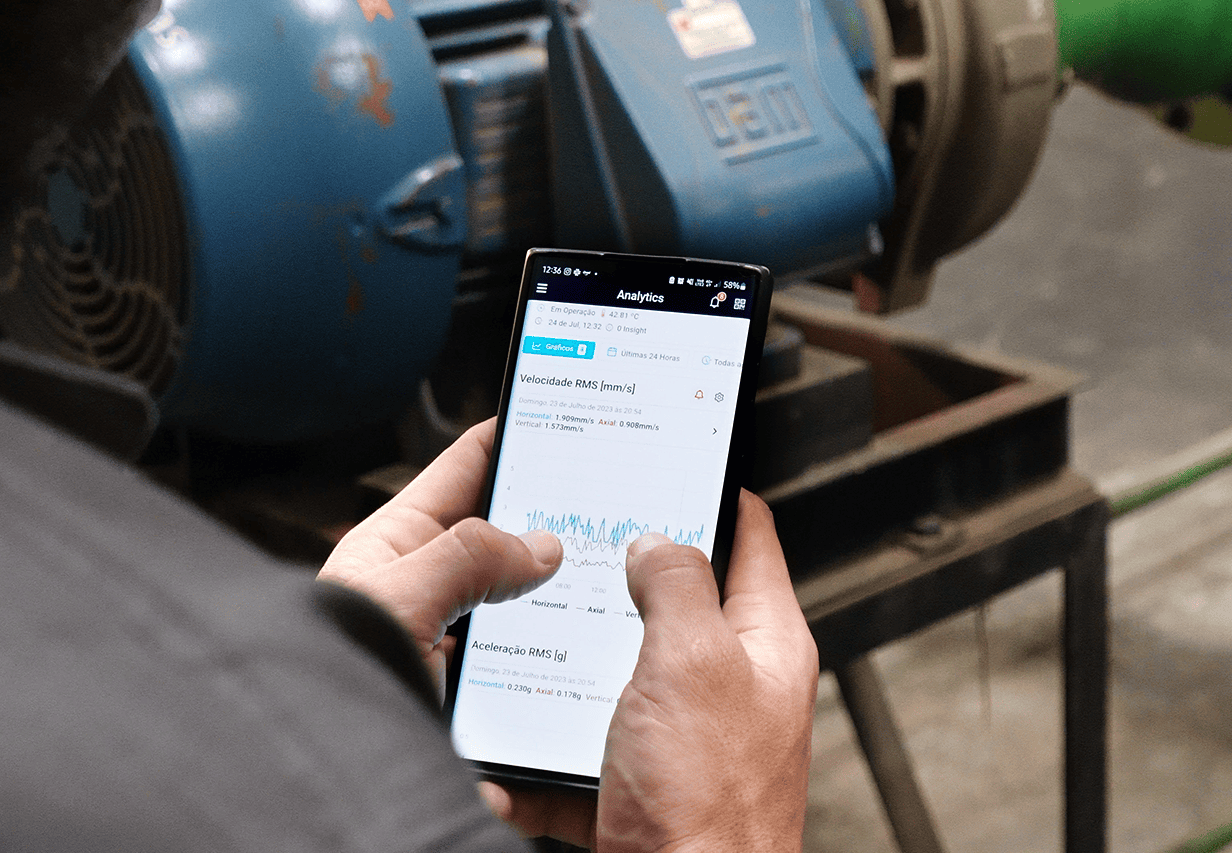

Use real-time alerts, streamline work orders, and ensure that spare parts are readily available. Digital tools, such as CMMS platforms, can help automate, prioritize, and minimize delays in every maintenance task.

When Should You Track MTTR?

Always - especially for critical assets. MTTR should be part of your monthly KPI review. It reveals weak spots in your maintenance process and helps track improvements over time.

Why MTTR Alone Isn’t Enough

Pair it with MTBF and OEE for full visibility. MTTR shows how long repairs take. MTBF tells you how often they happen. OEE puts it all in context. Together, they show where efficiency is won and lost.

Why Does MTTR Matter in Maintenance Management?

Because it directly affects your uptime, costs, and customer experience. A lower MTTR means faster recoveries, fewer production disruptions, and more effective resource allocation. Here’s why it matters:

1. Minimizing Downtime

Downtime is expensive, and MTTR is your lever to control it. Every minute your equipment is down costs you in lost production and revenue. The faster you repair, the more uptime you get back.

2. Optimizing Resource Allocation

Knowing MTTR helps you plan better. From assigning the right technician to keeping critical spare parts stocked, understanding MTTR helps maintenance managers streamline planning and avoid waste.

3. Enhancing Equipment Reliability

Reducing MTTR pushes your team to act faster and smarter. This focus leads to process improvements that naturally increase equipment reliability and extend asset lifespan.

4. Improving Customer Satisfaction

In customer-facing industries, downtime is highly visible and can’t be concealed internally. Whether in manufacturing, healthcare, or hospitality, a lower MTTR increases trust through fewer disruptions and faster service recoveries.

How to Make the Most of the MTTR Calculator

Use it to look behind the numbers and fix what’s really disrupting production. The MTTR calculator provides more than just a metric. It helps pinpoint delays, guide team planning, and benchmark improvements.

Here’s how to maximize it:

- Track regularly: Weekly or monthly tracking highlights trends, not just one-offs.

- Segment by asset: Break MTTR down by asset type, location, or failure mode to find bottlenecks.

- Compare before/after changes: Did a new SOP or part supply fix reduce repair time? MTTR will show you.

- Use it in team reviews: Share MTTR as part of your maintenance KPIs to drive awareness and accountability.

Best Practices for Improving Mean Time to Repair (MTTR)

To reduce MTTR you need to be smart about how to deal with failures. That’s where preventive and predictive maintenance come in.

Here’s how to reduce MTTR effectively:

- Use real-time alerts to cut response delays

- Digitize work orders for clarity and accountability

- Pre-stock critical spare parts to eliminate waiting time

- Standardize repair procedures for the most common failure types

- Train technicians to identify root causes faster

- Adopt preventive maintenance to fix issues before they escalate

- Leverage predictive maintenance to detect early warning signs using sensors and data