How to Calculate OEE (Step by Step)

OEE Score = Availability × Performance × Quality

The OEE calculation is a simple formula that reveals how much of your productivity is being lost due to production inefficiencies.

- Availability % = Running Time / Planned Production Time

Demonstrates actual uptime. If your machine was scheduled to run 8 hours, but stopped for 1 hour, then

Availability = 7 ÷ 8 = 87.5%

- Performance % = Ideal Cycle Time × Total Count / Running Time

Shows if you're producing parts slower than expected. If the ideal cycle is 1 min/part and you made 400 parts in 480 mins, then

Performance = (1 × 400) ÷ 480 = 83.3%

- Quality % = Good Count / Total Count

Tells you how many parts are actually usable. If 380 of 400 parts are usable (good), then

Quality = 380 ÷ 400 = 95%

Final OEE = 0.875 × 0.833 × 0.95 = 69.1%

This is your final OEE calculation. Multiply the percentages (as decimals) together to get the OEE score. In this example, using the availability, performance, and quality scores above, you're using 69.1% of your available production time effectively.

To state it another way, your production inefficiencies total 30.9% (100% - 69.1%).

What is Overall Equipment Effectiveness (OEE)?

OEE shows the percentage of your production time that is actually productive, as well as where you’re losing efficiency.

It combines three factors: Availability (uptime), Performance (ideal speed), and Quality (good parts).

The result is a single, powerful score that reveals potential opportunities to increase output and reduce waste in your production.

Why Use an OEE Calculator?

To stop guessing where your productivity losses occur.

An OEE calculator converts raw production data into clear metrics, enabling you to identify inefficiencies and take precise action.

Factors Affecting Overall Equipment Effectiveness (OEE)

Small inefficiencies in availability, performance, or quality can snowball into major production losses.

OEE drops when machines stop unexpectedly, run slower than expected, or produce unusable parts. Identifying which of these three factors is dragging your score down is the first step toward improving it.

When and How to Use OEE?

Use OEE anytime you want to understand where your production efficiency is being lost and how to improve it.

It’s ideal for shift analysis, line comparisons, or continuous improvement projects. Whether daily or monthly, OEE reveals how productive your plant’s output performance really is.

How Does Increased OEE Help?

Higher OEE means fewer delays, better product quality, and more efficient use of your current equipment.

It helps you meet demand, reduce rework, and increase throughput without needing to expand your production line.

Why Should I Know When OEE Goes Up and Down?

Fluctuations in OEE are signals. If your OEE rises, it shows what’s working. If it drops, it points to where you’re losing time or quality. Tracking both helps you identify and resolve root causes to sustain long-term gains.

How to Improve OEE?

Start by identifying which component-Availability, Performance, or Quality-is holding you back. Then tackle the root causes: unplanned stops, speed losses, or product defects. Even a small improvement in just one area can generate a significant boost in your OEE.

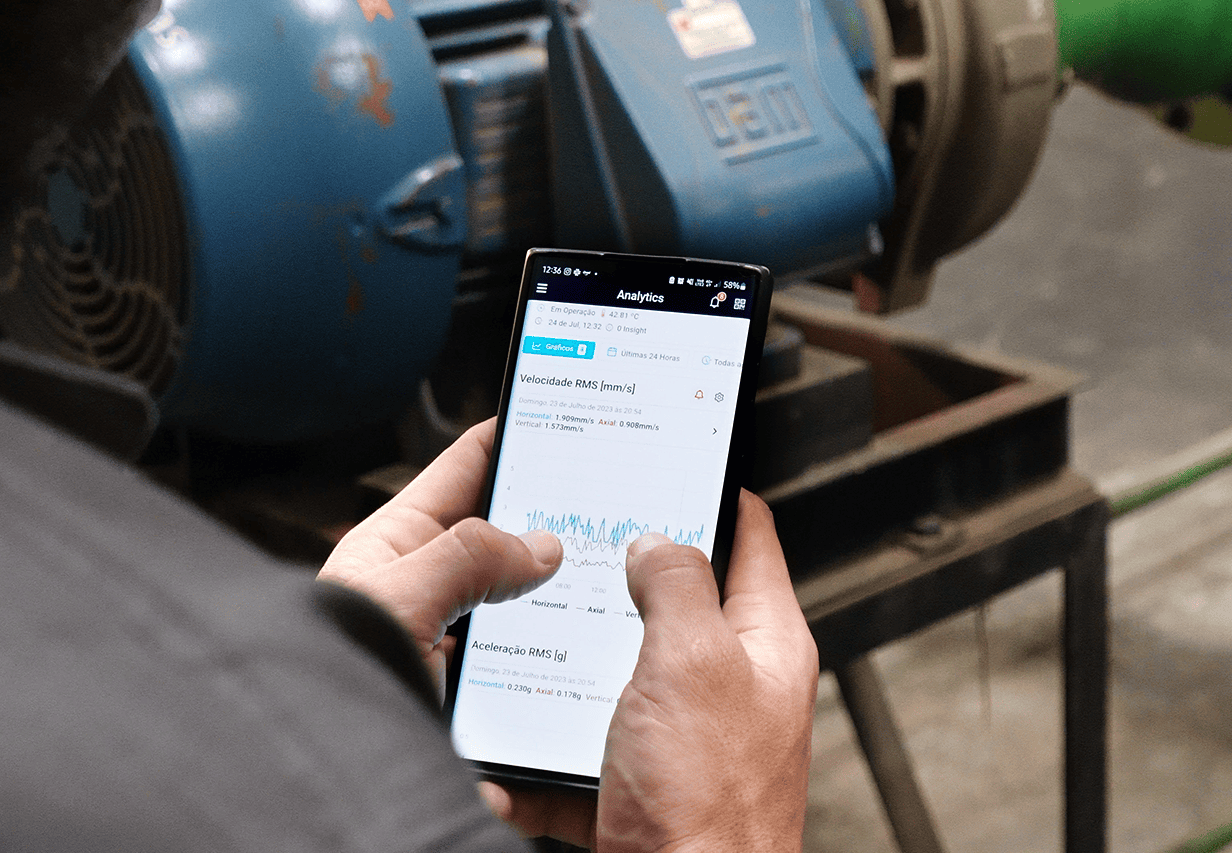

How Tractian Improves Your Factory

Go beyond manual calculation with Tractian’s real-time OEE monitoring, including live performance tracking and inefficiency diagnoses. Take action before disruptions become downtime.