How to Calculate Wrench Time (Step by Step)

Wrench Time = (Direct Work Time ÷ Total Time) × 100

This tells you what percentage of maintenance time is actually spent on physical repair or service work.

1. Direct Work Time

Total time spent on actual hands-on maintenance activities (e.g. repairs, inspections, installations).

2. Total Time

Includes all hours paid, both productive and non-productive (e.g. waiting for parts, paperwork, travel).

Example:

If a technician worked 8 hours but only 4 were spent on direct work:

Wrench Time = (4 ÷ 8) × 100 = 50%

What is Wrench Time and Why Does It Matter?

Wrench Time shows how efficiently your maintenance labor is being used. Higher wrench time means your team is working more productively. Low wrench time points to avoidable delays, miscommunication, or workflow problems.

What’s Included in Wrench Time (and What’s Not)?

Wrench Time includes:

✔ Hands-on time doing repairs, inspections, installations, replacements

✔ Time spent using tools on the asset

Wrench Time does NOT include:

✘ Walking to get parts

✘ Waiting for instructions or approvals

✘ Reading manuals or work orders

✘ Traveling between job sites

✘ Administrative tasks

What Causes Low Wrench Time?

Delays, unclear instructions, missing parts, or poor planning. When techs spend more time walking, waiting, or troubleshooting paperwork than actually repairing, your costs go up, and output drops.

What’s a Good Wrench Time Benchmark?

40%–60% is typical. Above 60% is considered strong. Perfect wrench time doesn’t exist, techs will always spend some time in transit or coordination. But if you’re under 30%, it’s a red flag.

How to Improve Wrench Time

Boosting wrench time is about removing friction from the workflow:

- Pre-stage tools, parts, and instructions

- Eliminate manual paperwork with mobile CMMS tools

- Improve communication between planners and technicians

- Use real-time tracking to see where time is being lost

- Train teams to self-report blockers in the process

How to Track Wrench Time Accurately (Without Overcomplicating It)

Most teams don’t track wrench time at all, or they do it inconsistently. To measure it accurately, you need to:

- Define what counts as direct work time

- Track total hours on the clock

- Encourage teams to self-report without blame

- Use categories like “waiting,” “travel,” and “non-value-added” to understand time loss

- Review results regularly to find repeat issues

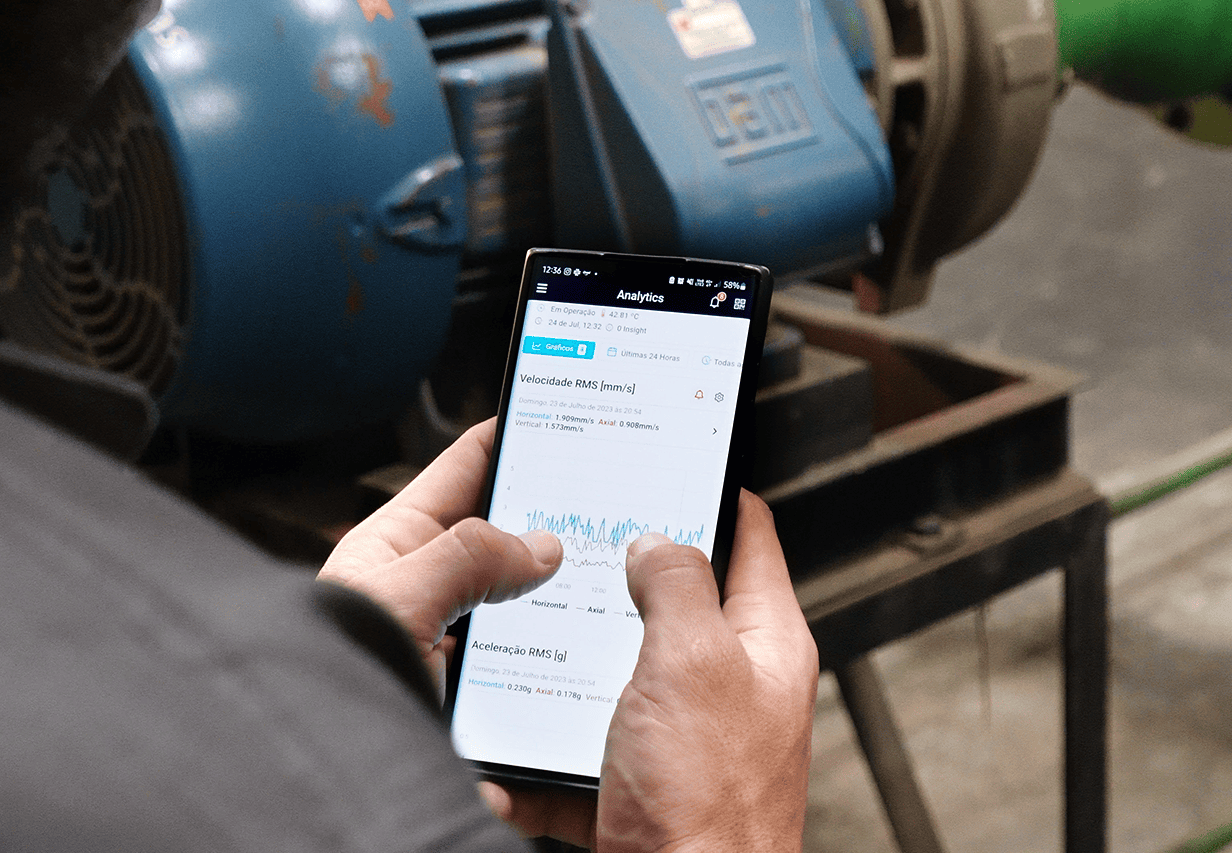

See How Tractian Increases Wrench Time with Smart Maintenance

Stop wasting skilled labor on avoidable delays. With Tractian, your team spends more time fixing problems and less time chasing parts, instructions, or approvals.

Here’s how:

- Digital work orders keep everything technicians need in one place

- Real-time asset data helps teams arrive prepared, not guessing

- Automatic time logs give clear visibility into wrench vs. non-wrench time

- Integrated task scheduling minimizes waiting and rework