What is a Vibration Sensor?

What is a Vibration Sensor, why you need to monitor vibrations and more.

What is a Vibration Sensor, why you need to monitor vibrations and more.

Vibration monitoring technology is pivotal for maintaining machine health, with vibration sensors providing maintenance teams with essential insights into equipment's internal state, averting potential failures.

These sensors facilitate a proactive maintenance strategy, and they should easily integrate into machinery to collect data accurately. The ideal predictive maintenance solutions leverage this data, offering automatic diagnostics to preempt extensive repairs, ensuring operational efficiency and reliability.

A vibration sensor is an instrument designed to quantify both the magnitude and frequency of vibrations within a specific system, machinery, or equipment. This data is instrumental in identifying imbalances or malfunctions within the asset, thereby enabling the prediction of potential future malfunctions.

Monitoring vibrations is crucial for industry plants that rely on heavy machinery for its day-to-day operations. The benefits of implementing vibration monitoring are significant and include:

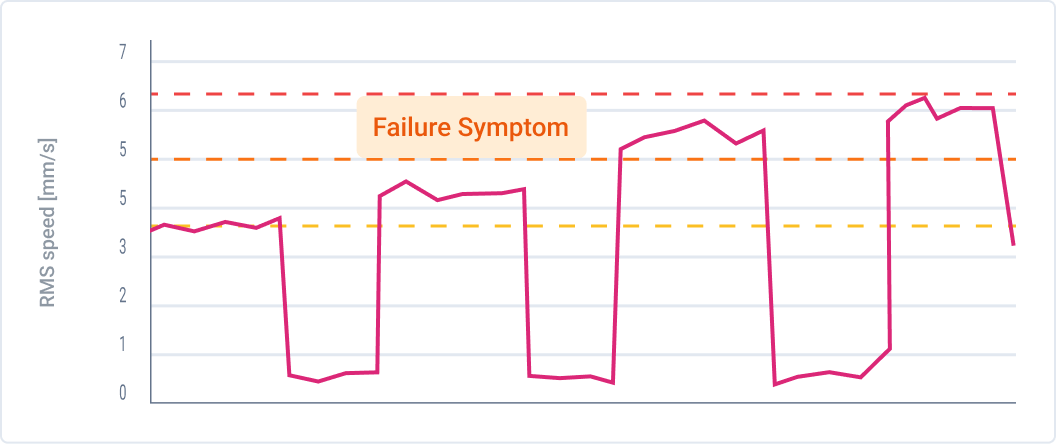

Vibration analysis is a powerful tool for root cause analysis (RCA) when equipment begins to exhibit wear signs. By keeping track of vibrations within the machinery, it's possible to pinpoint the initial source of vibrations and the resulting damage.

Beyond aiding in RCA, vibration monitoring is particularly effective for predictive maintenance. Integration with a Computerized Maintenance Management System (CMMS) or a similar platform allows for the real-time tracking of vibration data. Observing spikes in vibration levels signals the immediate need for maintenance on the affected machinery.

Condition monitoring extensively utilizes sensors, including those for vibration, to maintain a continuous check on the health of critical machinery. Monitoring vibrations enables the observation of equipment performance over specific periods.

A vibration sensor can be either directly attached to an asset or used to monitor it from a distance through wireless technology. Once installed, it captures vibration signals from the asset using a variety of methods, specific to the sensor type. Over time, this device provides two key pieces of information:

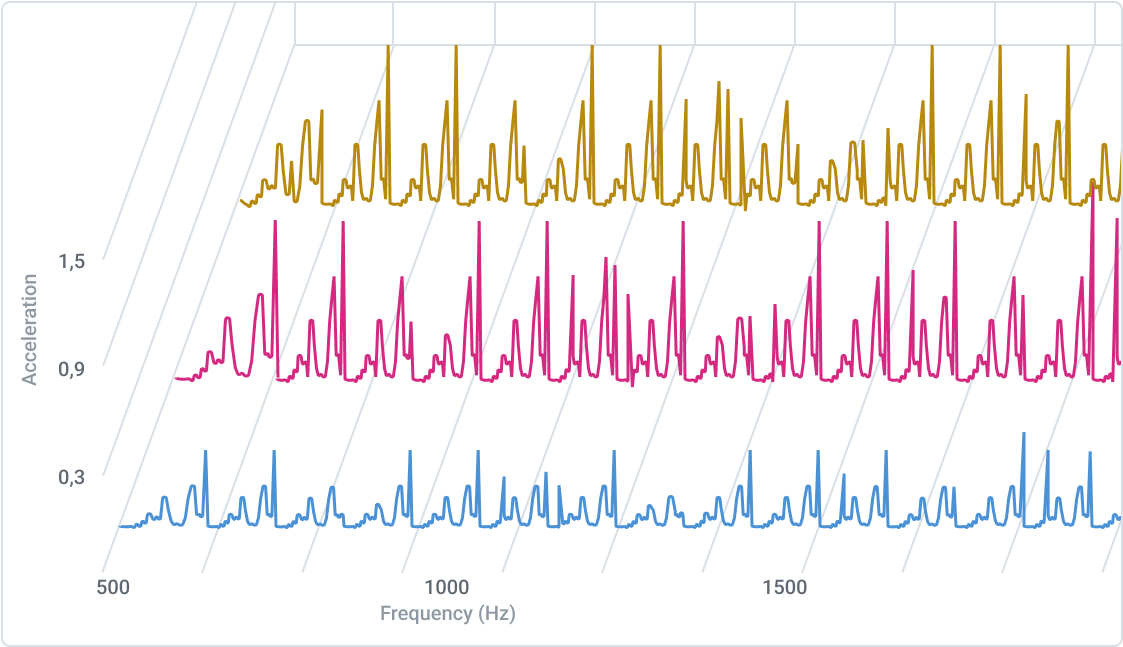

Frequency: This data represents how frequently vibrations occur within the asset. Monitoring the timing of vibration spikes allows for the identification of underlying issues.

Intensity: This measures the strength of the vibrations emitted by the equipment. Higher levels of vibration lead to greater intensity readings.

Note: The term 'frequency' has dual meanings based on the context. In this scenario, it refers to the occurrence rate of vibration peaks. Conversely, in other situations, it might denote the vibration's wavelength, which could influence intensity readings.

As this information accumulates, it's recorded in the asset's historical log within your Computerized Maintenance Management System (CMMS), serving as a benchmark for comparison. This historical data, reflecting any malfunctions, enables the system to forecast potential failures and issues by analyzing current data against past patterns.

By leveraging vibration sensors, industries can proactively manage maintenance needs, ensuring machinery longevity and operational efficiency. We summed up some equipment but every rotating machine can benefit from vibration sensing.

Crucial in the water and wastewater sectors, ensuring the operational integrity of water pumps and condensers is vital. Vibration sensors monitor these systems to preempt failures that could disrupt water supply and harm the environment.

These systems are foundational in various industries, with vibration monitoring essential for detecting imbalances that could escalate into broader system failures. For example, in the food and beverage industry, motor failure in chillers can result in significant product loss.

Used across numerous industrial applications, these systems require smooth operation. Vibration data can reveal early signs of wear or imbalance, allowing for timely maintenance interventions

Given their scale and the operational hazards of manual inspections, vibration monitoring offers a safer, more efficient alternative for maintaining these large rotating machines. It enables early detection of imbalances, facilitating prompt maintenance actions.

Integral to the smooth operation of rotating machinery, bearings require regular lubrication to prevent wear-induced vibrations. Vibration monitoring alerts maintenance teams to lubrication needs, averting more costly repairs down the line.

In the diverse world of vibration sensors, each type has its niche within industrial applications. However, accelerometers stand out as the premier choice in modern solutions for several compelling reasons:

Accelerometers operate across a wide frequency spectrum,, making them versatile for various machinery and applications.

Their reduced weight and dimensions allow for easy integration into different systems without affecting the machinery's operation or balance.

These sensors exhibit minimal sensitivity to lateral and transverse vibrations and magnetic fields, ensuring accurate readings in complex industrial environments.

Accelerometers are designed to withstand harsh conditions, including shocks, falls, moisture, dust, oil, and other contaminants, making them reliable for long-term use in demanding settings.

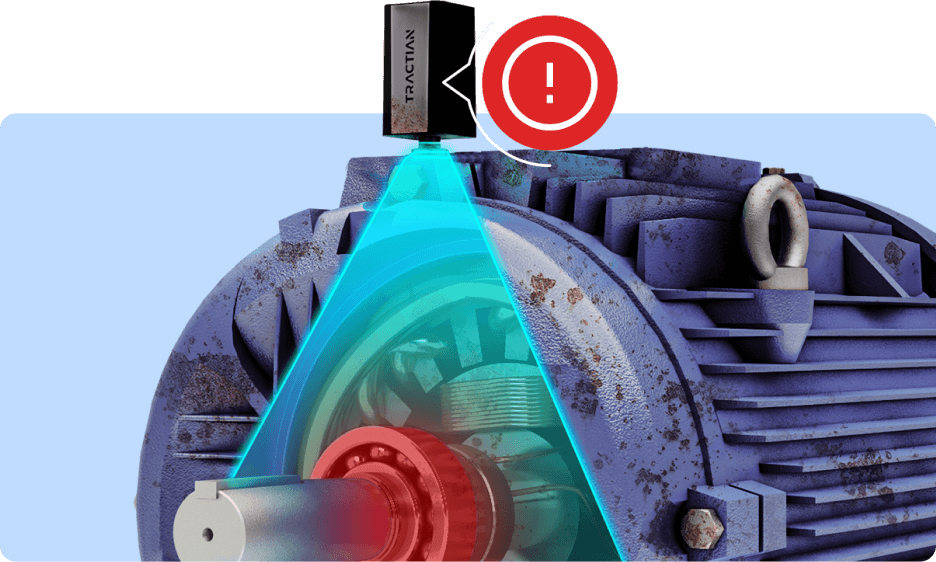

In the realm of industrial maintenance, the Smart Trac sensor by TRACTIAN emerges as a groundbreaking solution, seamlessly blending with the essential practice of vibration monitoring. Here’s why Smart Trac is not just another vibration sensor, but a leap towards smarter, more reliable machinery:

• Rapid Deployment: with a setup time of just 3 minutes, Smart Trac is designed for efficiency. Its patented technology ensures it stands alone as the most advanced option in the predictive maintenance landscape, boasting 4G/LTE connectivity for uninterrupted real-time data transmission.

• Comprehensive Fault Detection: capable of anticipating and diagnosing over 70 types of faults, Smart Trac is your frontline defense against unexpected equipment failures. This sensor doesn't just alert you to problems; it guides you through to solutions, enhancing operational efficiency while slashing maintenance costs.

• Data-Driven Predictive Maintenance: Smart Trac's unique and exclusive technology offers objective data collection, free from external interference. It consistently gathers information, allowing for precise fault detection by focusing solely on the temperature and vibration data relevant to your asset's health.

• Immediate and Accurate Health Reports: within just 5 days of installation, receive an accurate health report of your asset through vibration analysis. Smart Trac enhances machine behavior understanding, identifying potential failures from the get-go.

• Designed for Critical Industrial Equipment: Smart Trac is the choice for companies with critical equipment requiring constant vigilance. It's a tool for those committed to boosting operational efficiency, reducing maintenance costs, and eliminating unscheduled downtime.

• Unmatched Durability and Connectivity: built to withstand the toughest conditions, including steam, high-pressure water jets, and extreme temperatures, Smart Trac ensures longevity with up to three years of battery life and includes 4G connectivity, eliminating the need for industrial WiFi.

• Effortless Integration and Immediate Insights

• Quick Setup: Attach and start monitoring within minutes, reducing downtime and technical hurdles

• High-Frequency Data Acquisition: Capture triaxial vibration data up to 32kHz every 5 minutes for comprehensive analysis

• Temperature Monitoring: Track surface temperatures up to 90°C, with automatic trend deviation alerts

• Durable and Dependable

• IP69K Resistance: Withstand steam, high-pressure water jets, and more for uninterrupted operation

• Long Battery Life: Up to 3 years of operation with 3G/4G connectivity included, ensuring reliable long-term monitoring

• Data-Driven Maintenance Decisions

• Automatic Operation Hours Calculation: Utilize vibration levels to accurately calculate machine operation times

• Prescriptive Insights and Spectral Analysis: Access automatic MTBF, MTTR, and MTTA indicators and detailed reports for informed maintenance planning

The main goal of maintenance is simple: to improve performance and increase profits. In order to achieve these, teams...

Predictive maintenance, especially through real-time data sampling and vibration monitoring, has emerged as a game-changer in the quest for operational reliability...

The expression ‘time is money’ has never been more accurate than in today’s fast-paced industrial landscape, particularly when it comes to machinery maintenance...

Monitor your industrial equipment precisely and in real time. Avoid unexpected failures, reduce maintenance costs and increase operational efficiency.