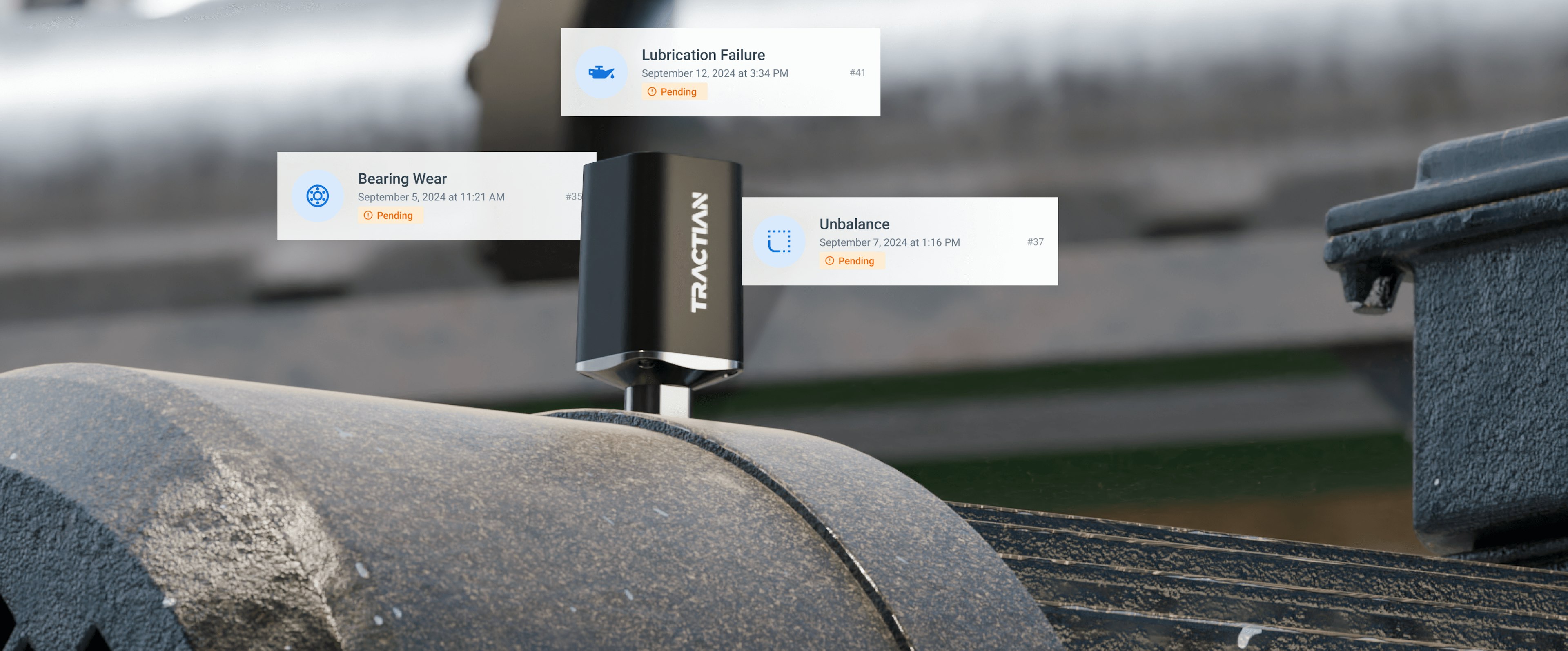

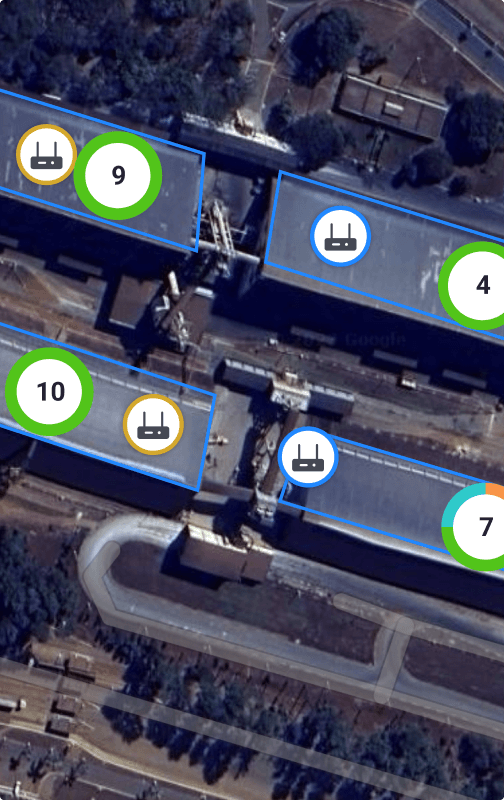

AI-POWERED CONDITION MONITORING

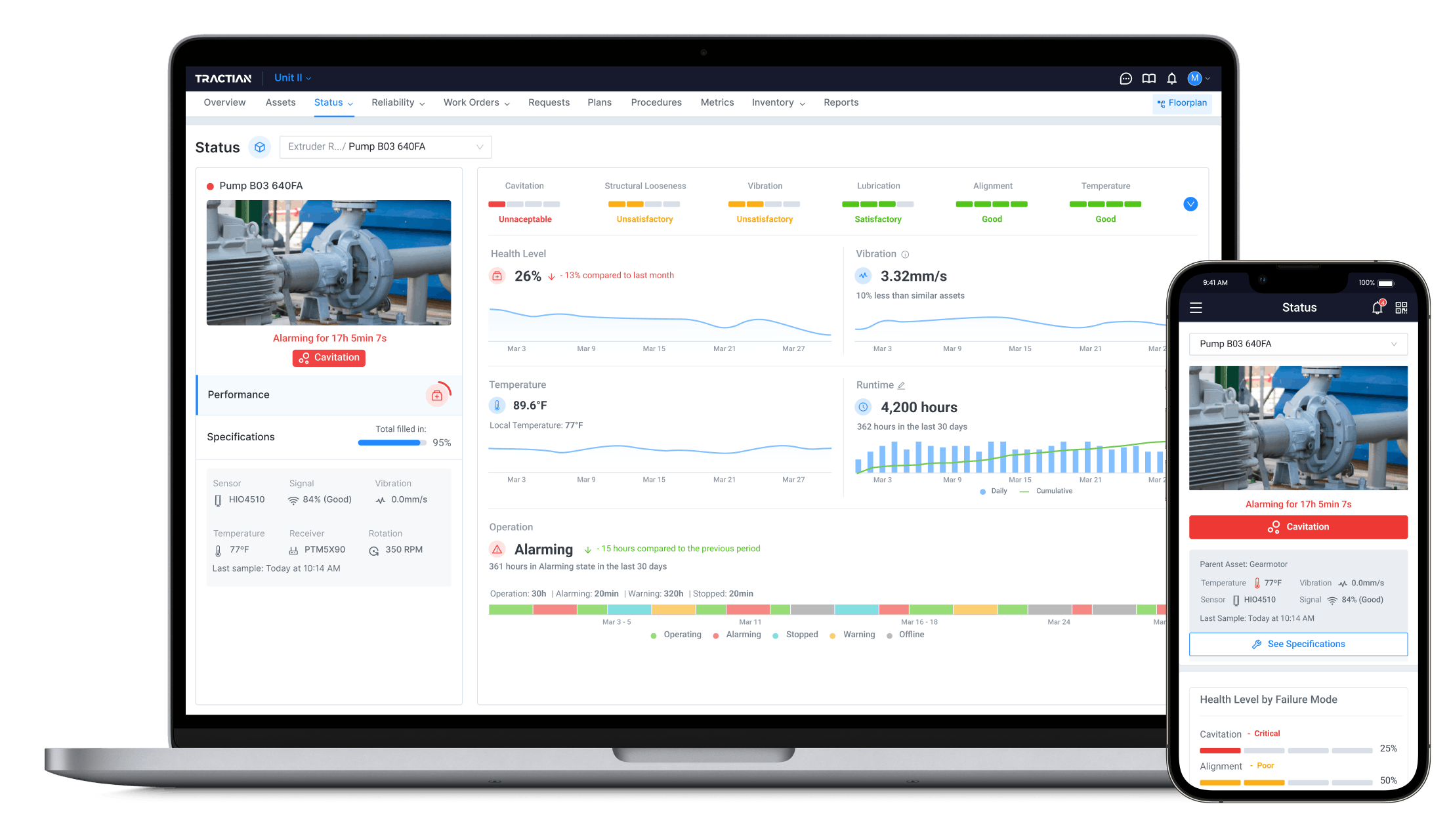

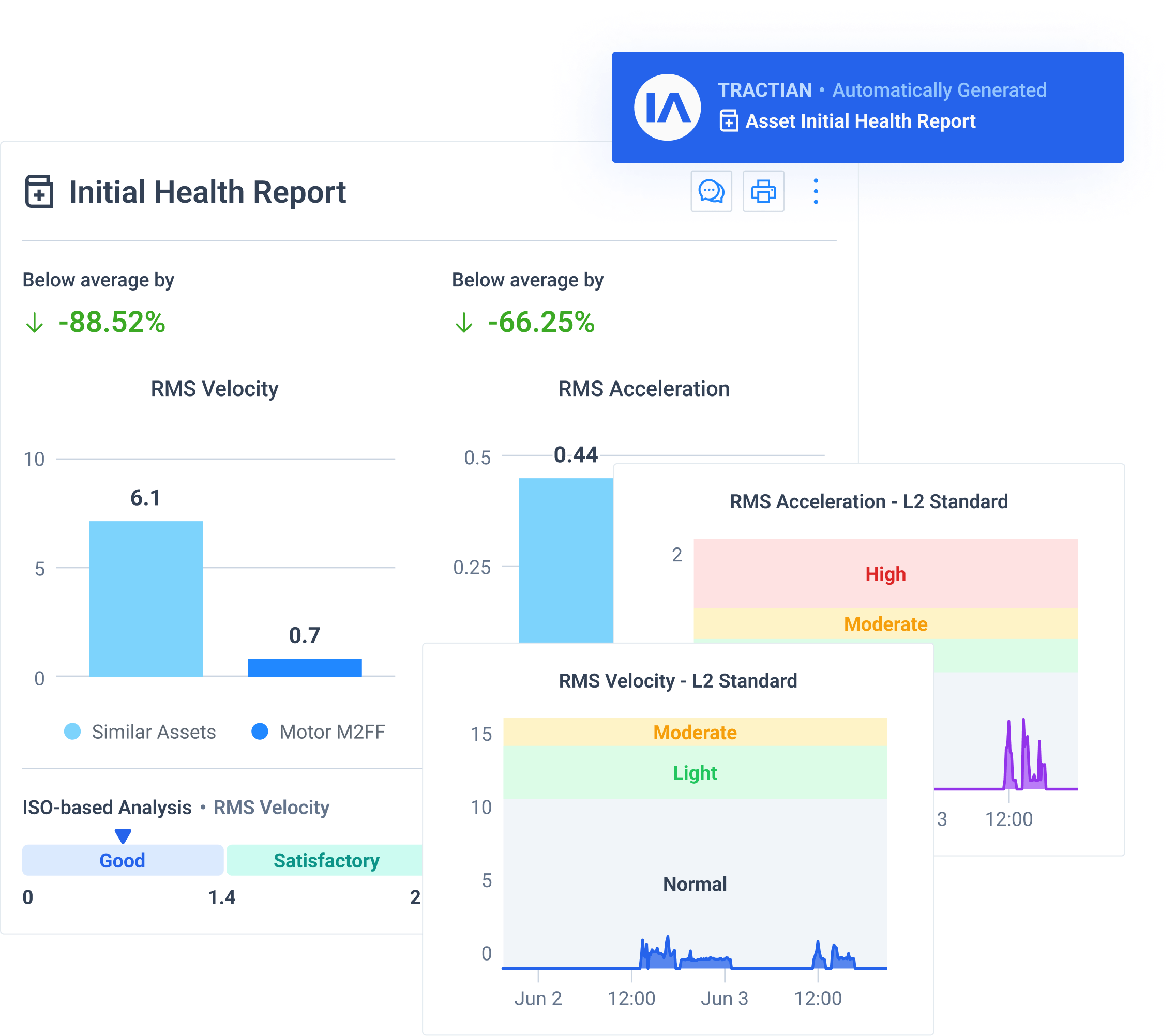

Advanced Condition Monitoring Software for Failure Detection

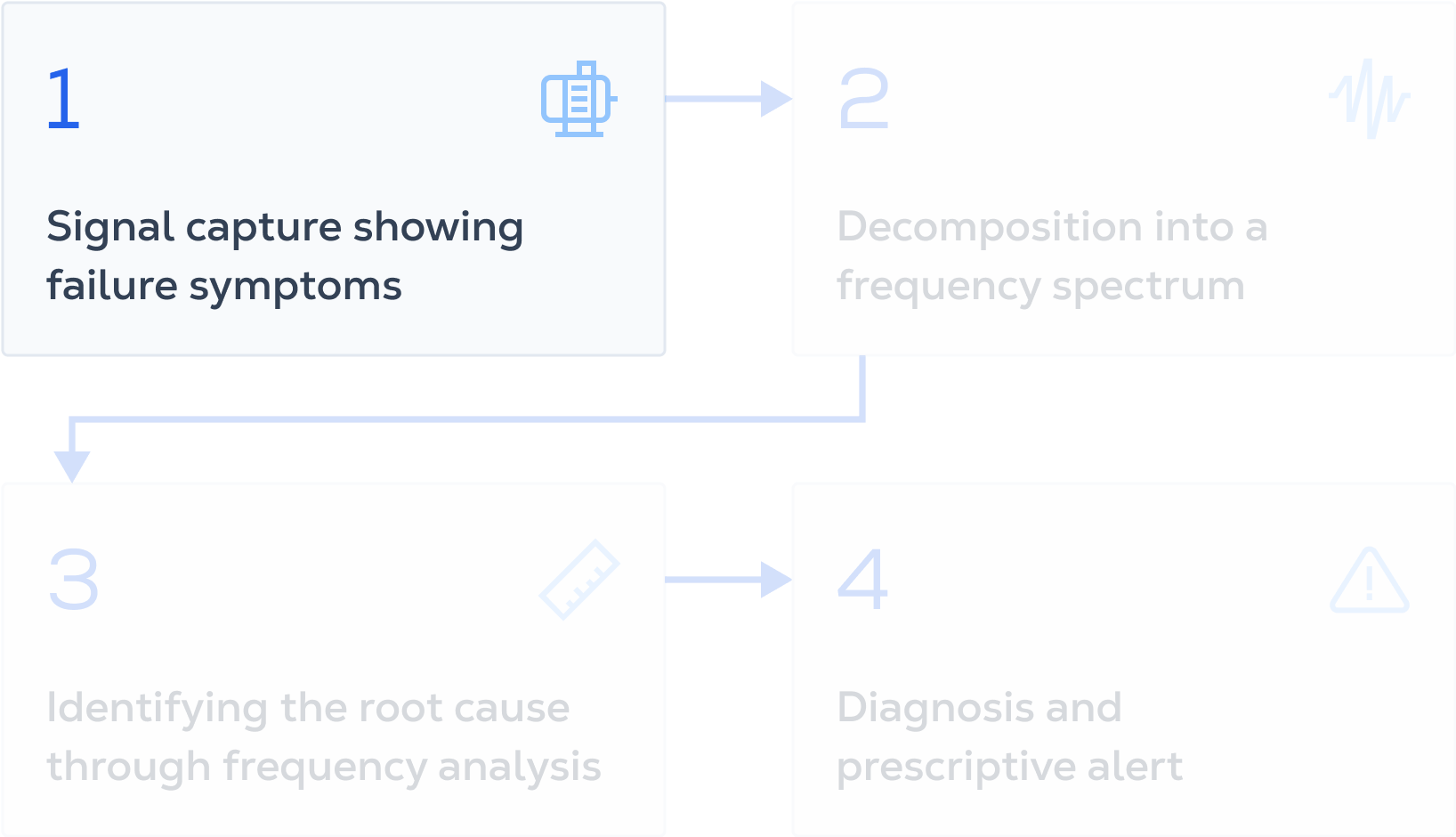

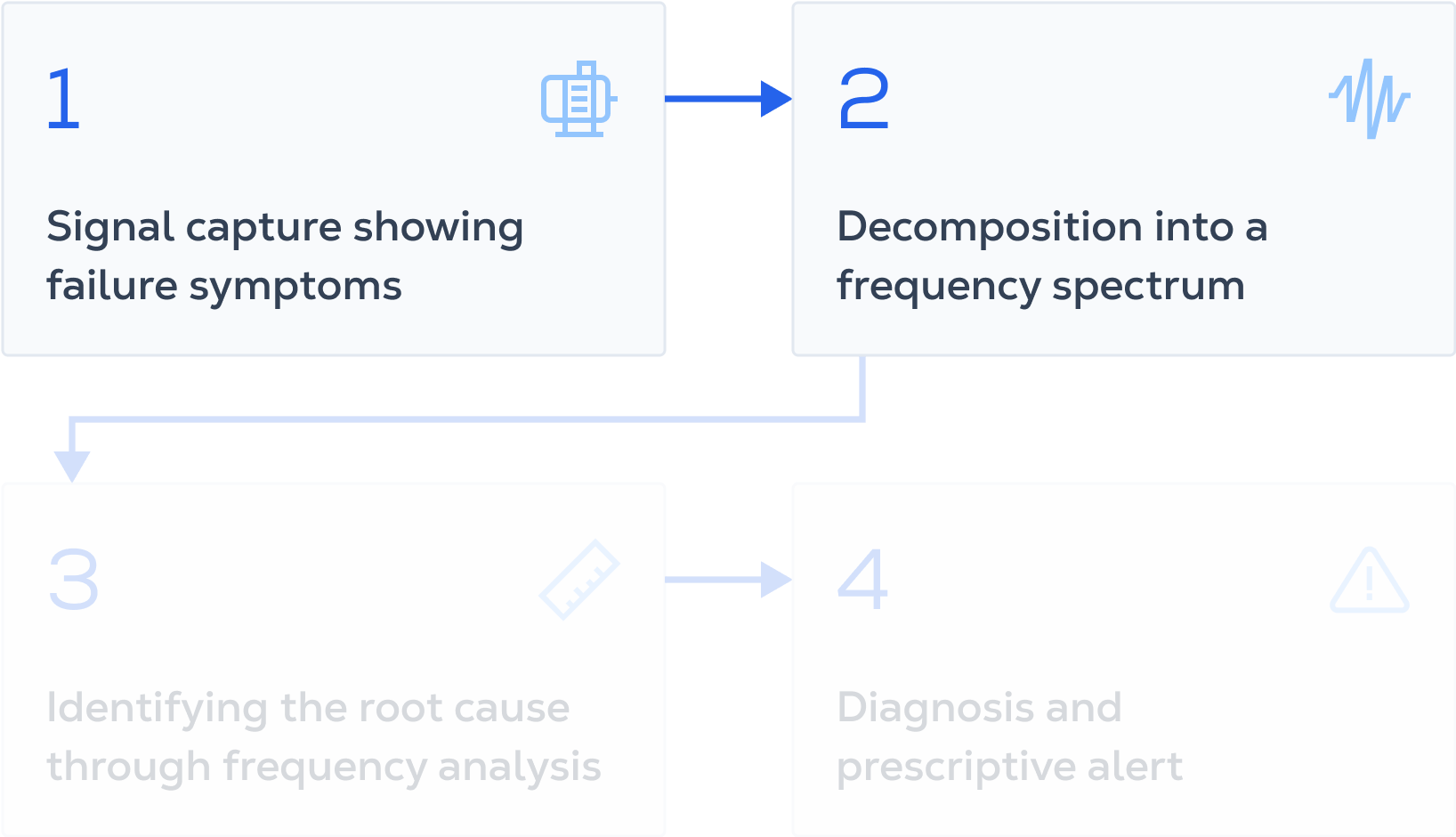

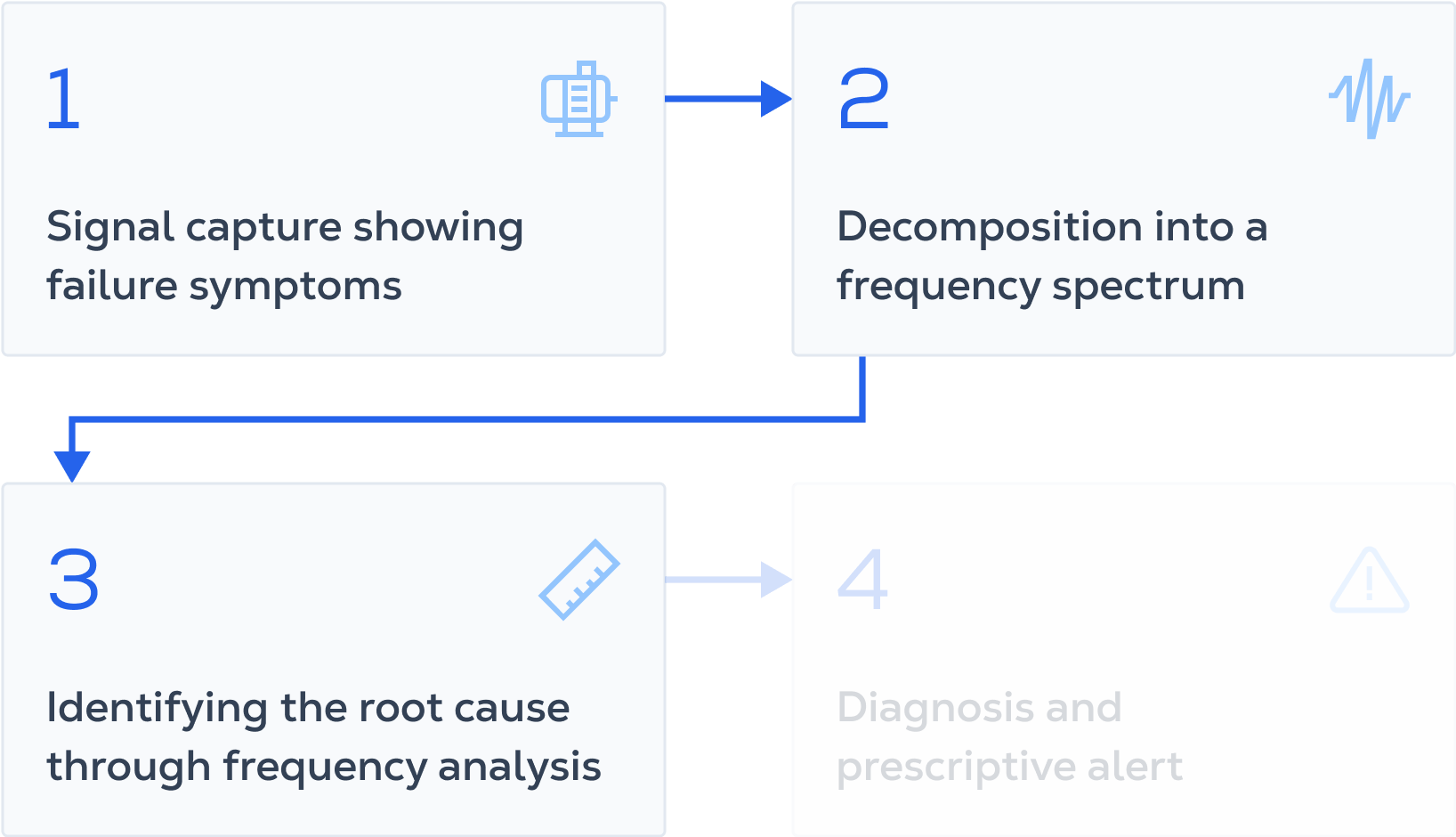

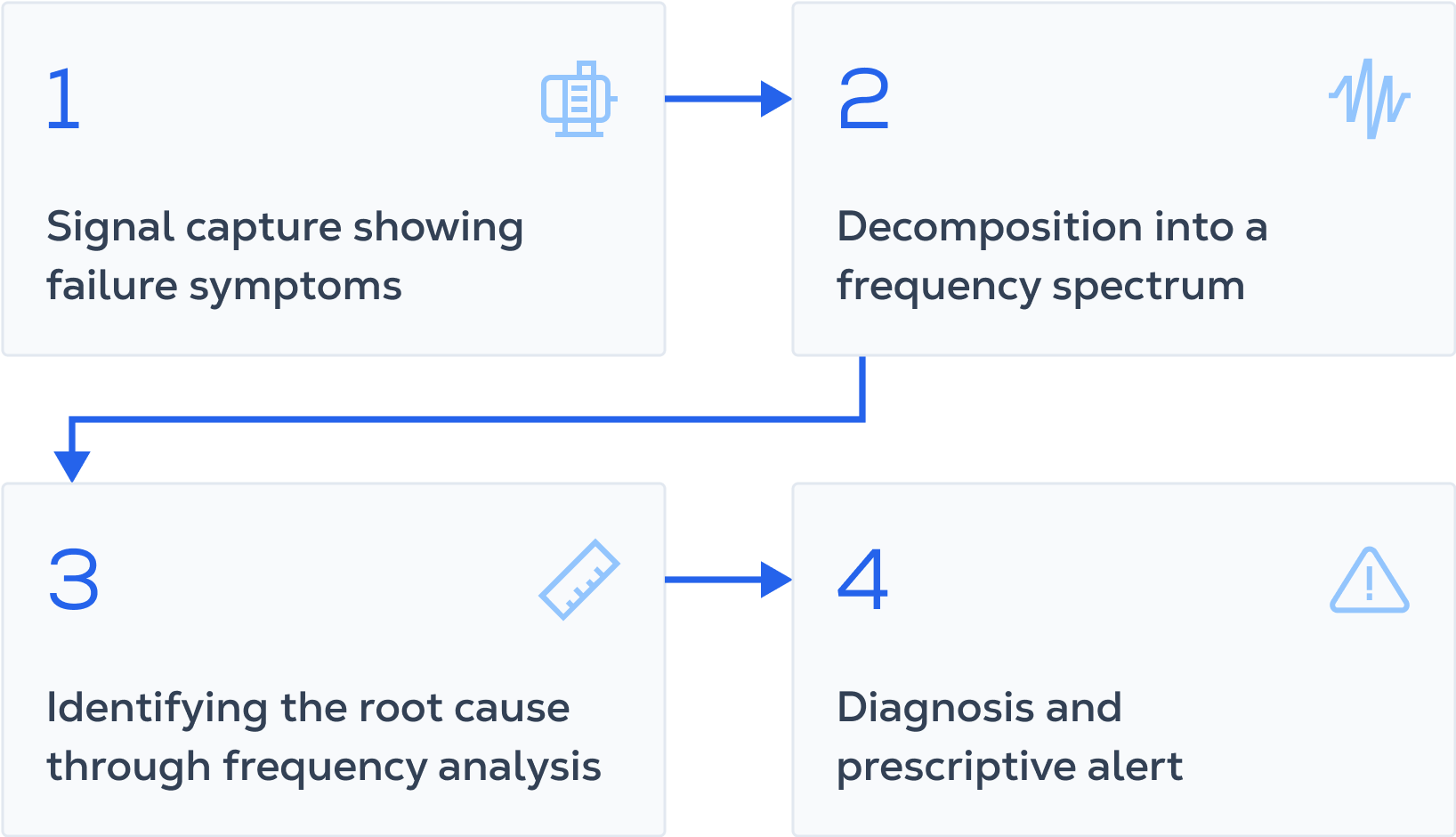

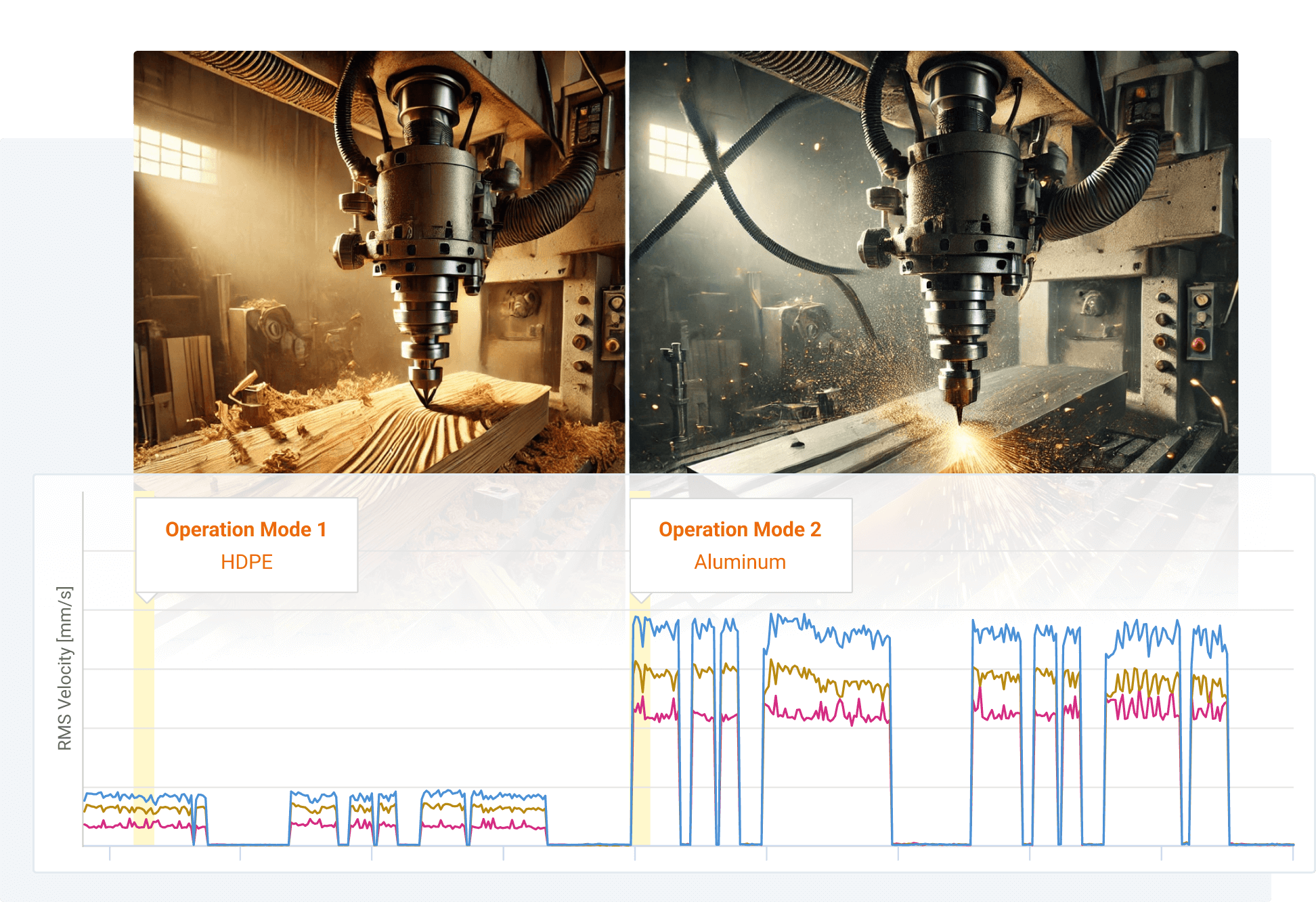

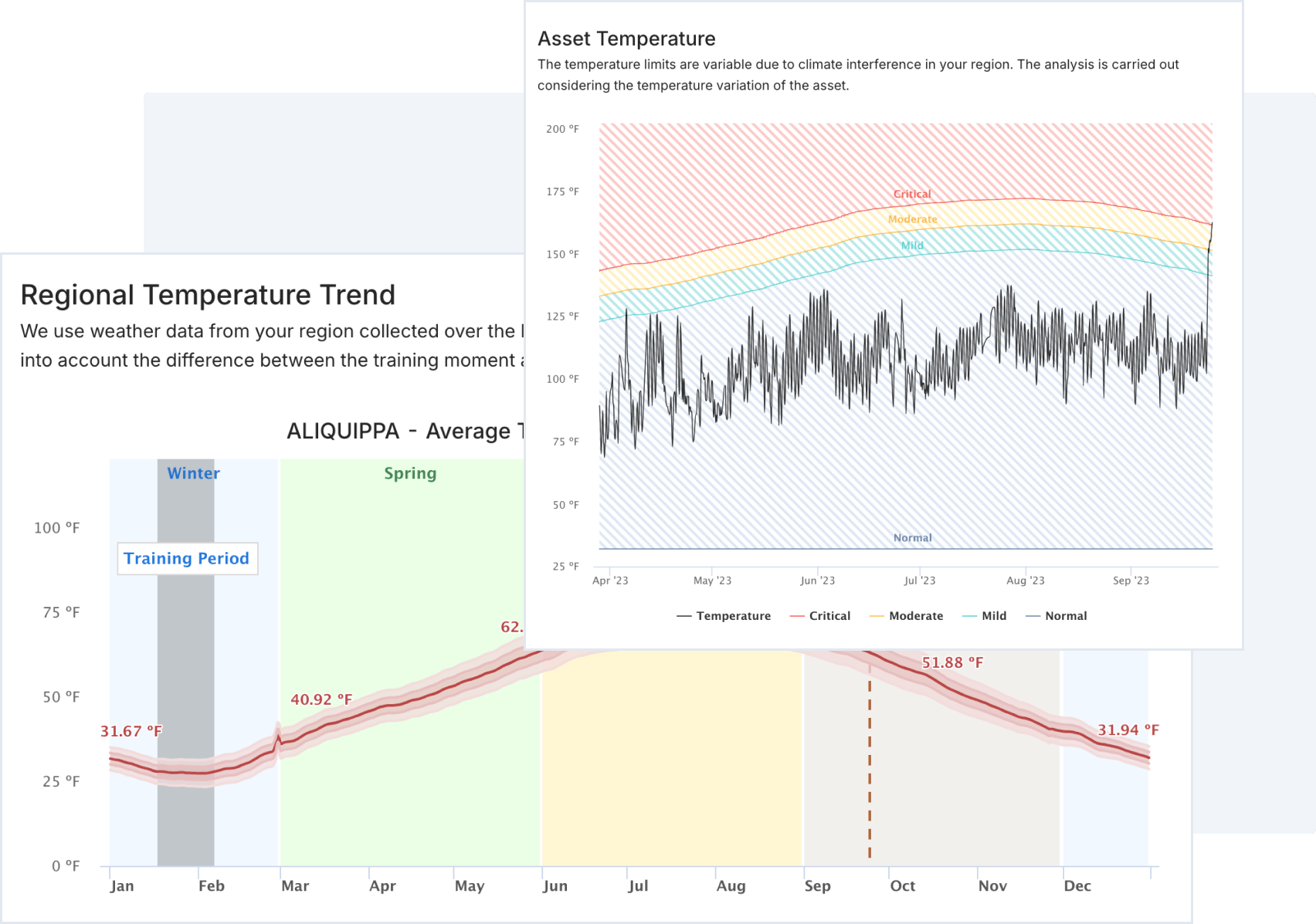

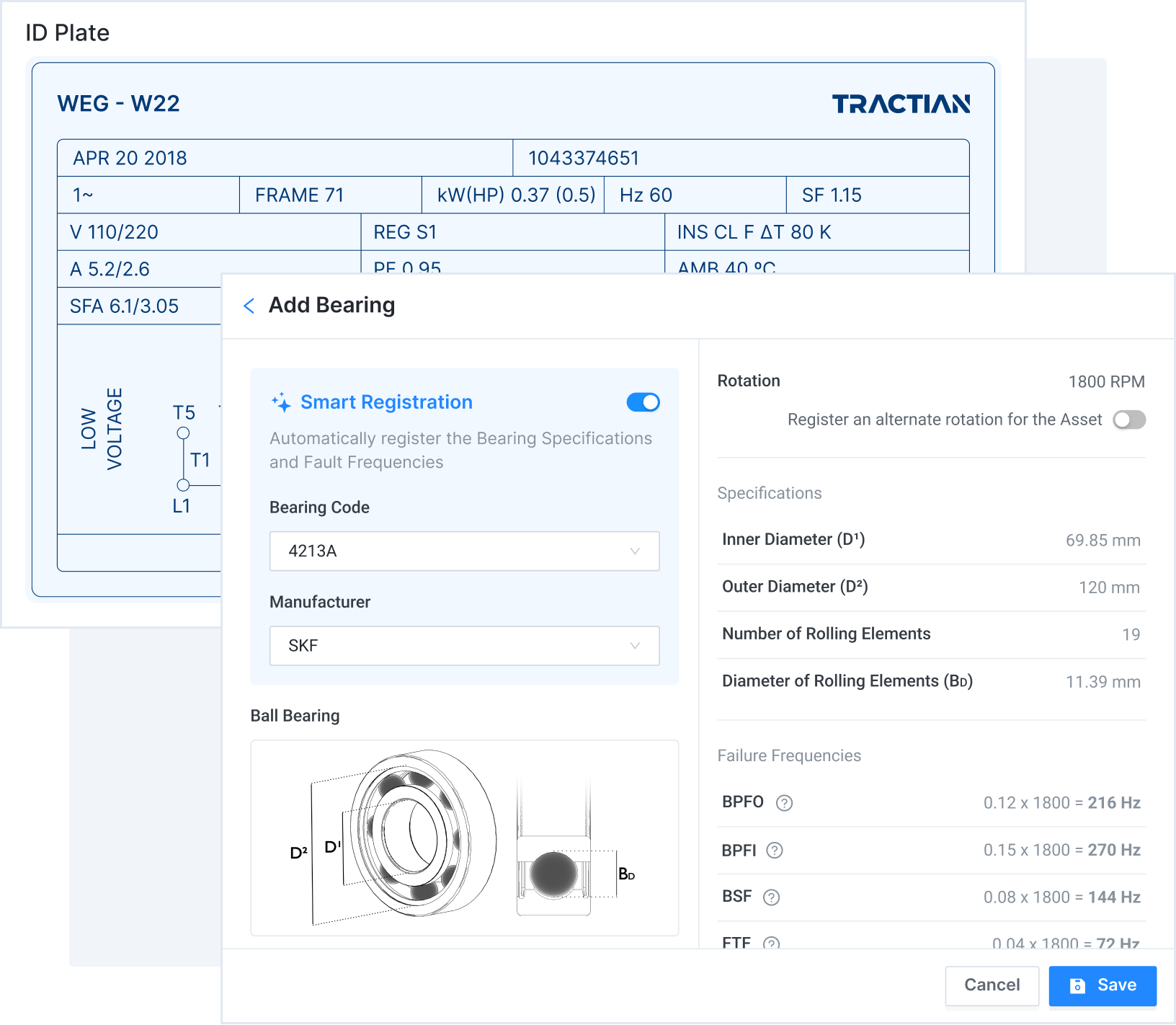

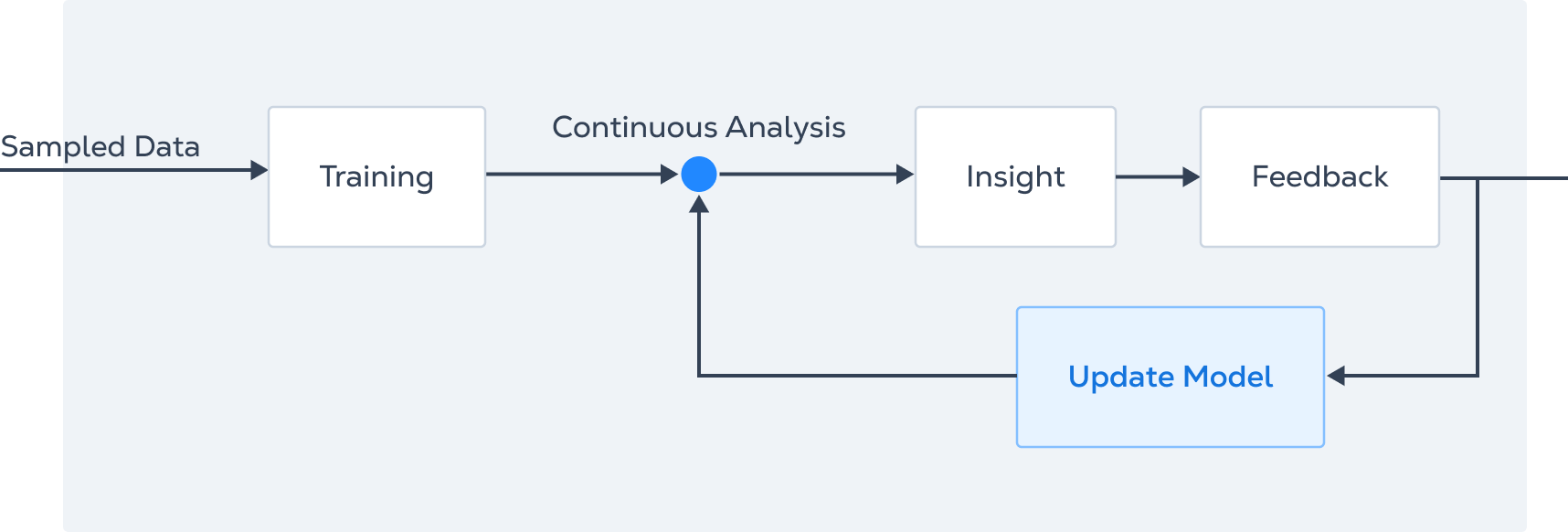

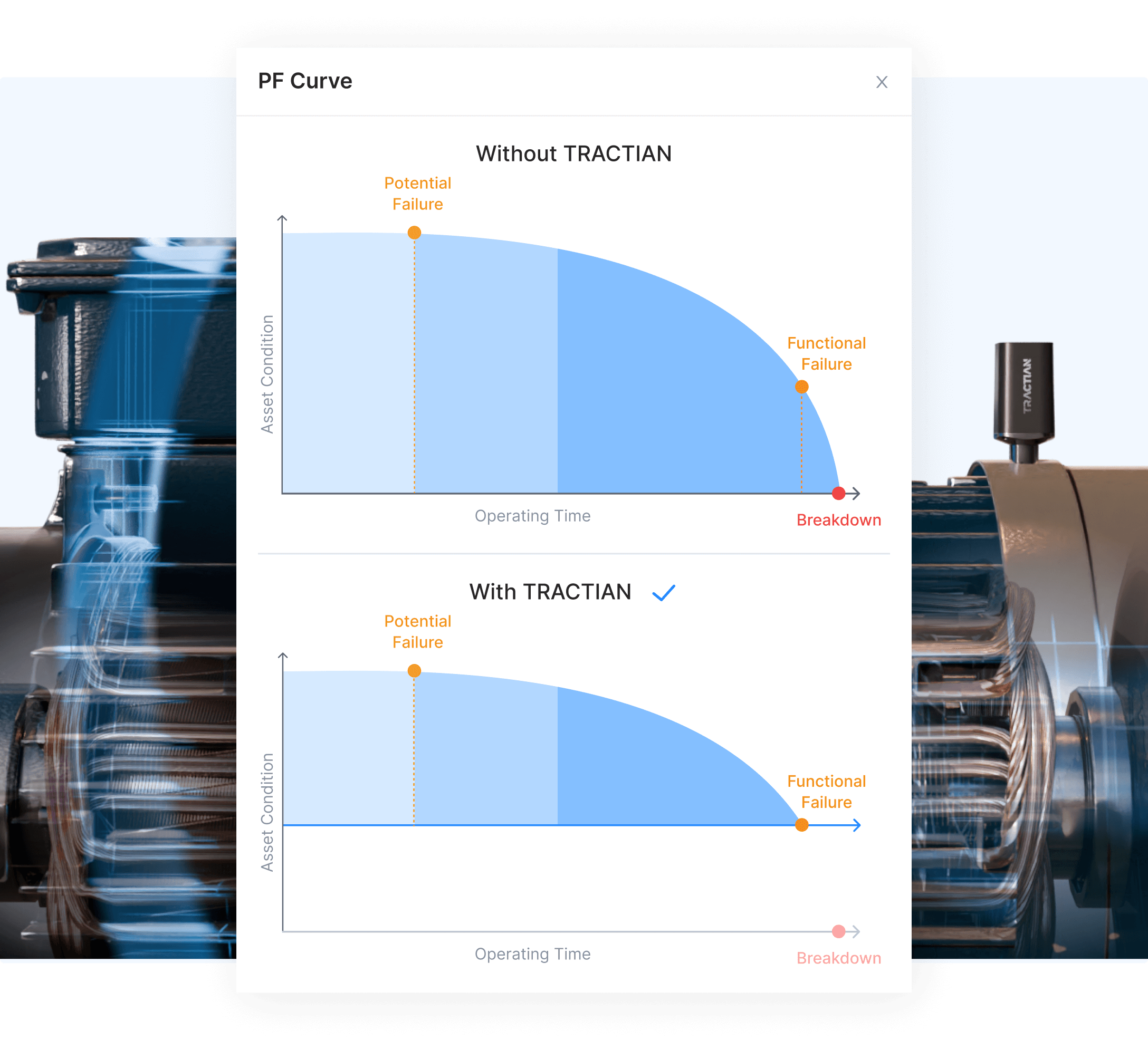

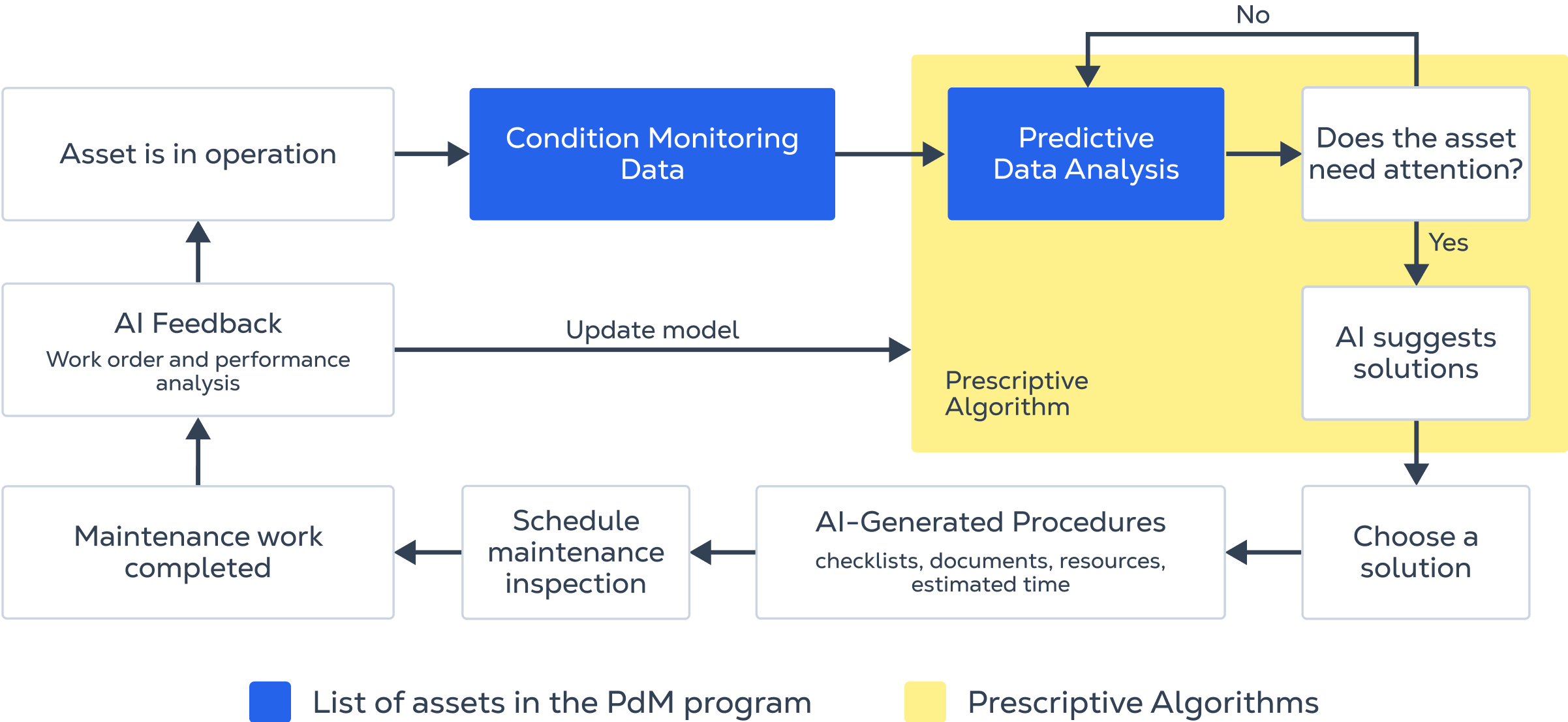

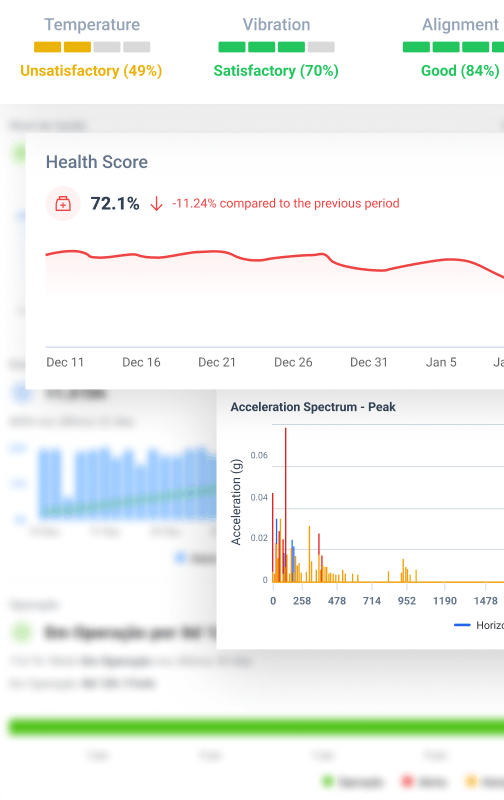

Identify issues before they affect machine health and get clear guidance on how to address them. Our patented algorithms redefine failure detection, enabling fast, precise interventions that boost asset availability.