- Free Resources

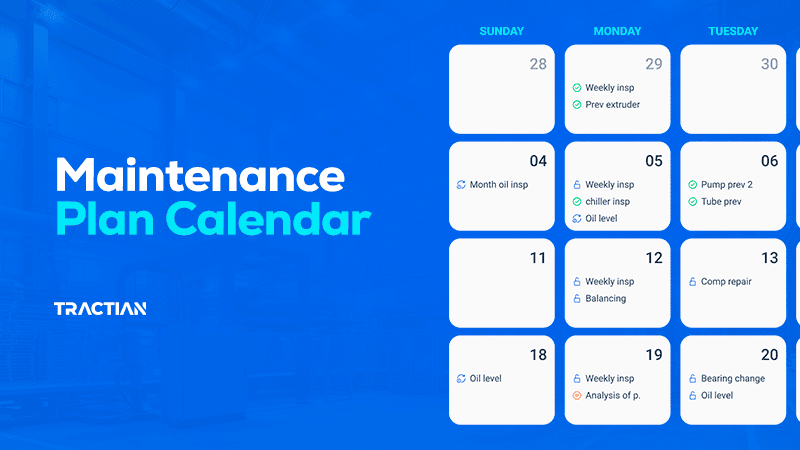

Maintenance Plan Calendar

Your material is almost ready!

Just complete a quick registration, and your material will be available.

Maintenance Plan Calendar

Just complete a quick registration, and your material will be available.

A Maintenance Plan Calendar is an annual tool that helps maintenance teams strategically schedule their inspections and preventive and predictive activities.

It allows managers and technicians to structure their essential maintenance routines, ensuring no task is overlooked.

With a well-defined plan, you can avoid unexpected failure and optimize resources, all while bringing predictability, efficiency, and better cost control to your operations.

This calendar follows a 52-week cycle to align maintenance schedules with asset criticality and operational needs.

Lack of structured maintenance planning typically leads to higher costs, unanticipated failures, and diminished operational efficiency. With this Maintenance Plan Calendar, you get a clear, strategic overview of your yearly maintenance activities:

✅ Minimize unexpected failures – Detect potential issues early and prevent unplanned downtime.

✅ Boost team productivity – Optimize technicians' time and reduce rework.

✅ Decrease waste and unnecessary expenses – Gain full control over work orders and allocated resources.

✅ Improve planning and coordination – Align maintenance schedules with operational demands.

This spreadsheet offers a practical way to track and schedule all maintenance tasks efficiently.

Step-by-step guide:

1️⃣ Download the file and make a copy to edit in Google Sheets or Excel.

2️⃣ List all assets and sub-assets, categorizing them by criticality and maintenance needs.

3️⃣ Define maintenance tasks (inspections, lubrication, part replacements, adjustments, etc.).

4️⃣ Set the ideal frequency for each task: daily, weekly, biweekly, monthly, quarterly, semi-annually, or annually.

5️⃣ Track and update task statuses to ensure everything runs according to plan.

A Maintenance Plan Calendar is an annual tool that helps maintenance teams strategically schedule their inspections and preventive and predictive activities.

It allows managers and technicians to structure their essential maintenance routines, ensuring no task is overlooked.

With a well-defined plan, you can avoid unexpected failure and optimize resources, all while bringing predictability, efficiency, and better cost control to your operations.

This calendar follows a 52-week cycle to align maintenance schedules with asset criticality and operational needs.

Lack of structured maintenance planning typically leads to higher costs, unanticipated failures, and diminished operational efficiency. With this Maintenance Plan Calendar, you get a clear, strategic overview of your yearly maintenance activities:

✅ Minimize unexpected failures – Detect potential issues early and prevent unplanned downtime.

✅ Boost team productivity – Optimize technicians' time and reduce rework.

✅ Decrease waste and unnecessary expenses – Gain full control over work orders and allocated resources.

✅ Improve planning and coordination – Align maintenance schedules with operational demands.

This spreadsheet offers a practical way to track and schedule all maintenance tasks efficiently.

Step-by-step guide:

1️⃣ Download the file and make a copy to edit in Google Sheets or Excel.

2️⃣ List all assets and sub-assets, categorizing them by criticality and maintenance needs.

3️⃣ Define maintenance tasks (inspections, lubrication, part replacements, adjustments, etc.).

4️⃣ Set the ideal frequency for each task: daily, weekly, biweekly, monthly, quarterly, semi-annually, or annually.

5️⃣ Track and update task statuses to ensure everything runs according to plan.

In addition to the Maintenance Plan Calendar, use our Maintenance Management & Work Order Control Spreadsheet to log and track all maintenance activities.

Download Bonus SpreadsheetFAQ

Yes! You can download and use it for free.

No. You can use it in Google Sheets (online) or Excel (offline).

Yes! The tool is flexible and can be adjusted based on your assets and operational processes.

With a 52-week overview of your preventive, predictive, and inspection tasks, you’ll have better operational control, enabling cost reductions and improved efficiency.

Yes! We recommend using the Maintenance Management & Work Order Control Spreadsheet for detailed tracking of executed maintenance activities.

Explore all the materials we offer for free to help you grow professionally and elevate your industry expertise.

Spreadsheet

Maintenance Indicators

Control the main maintenance indicators in a single place, such as MTBF, MTTR, and MTTA, with formulas and graphs.

Access Material

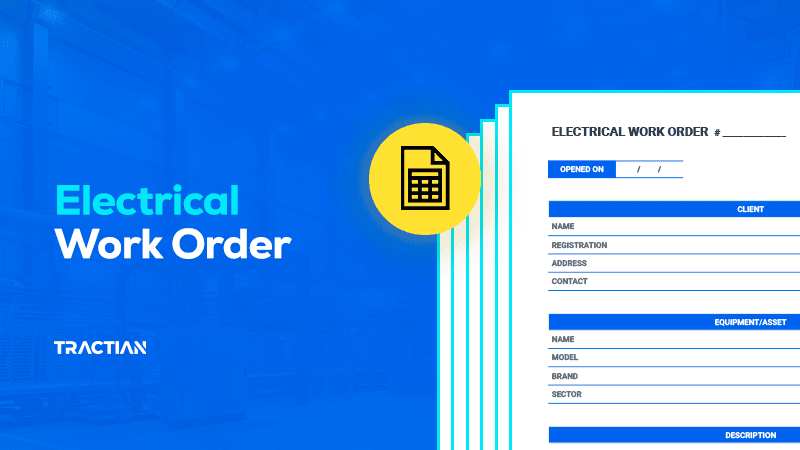

Work Order

Electrical WO

Prevent electrical failures through accurate maintenance control, performing frequent preventive maintenance.

Access Material

Work Order

Inspection WO

With this document it is possible to make sure that all plant assets are in full operation - especially the critical ones.

Access Material