Introducing Tractian OEE, a solution for process and production monitoring solution, designed to redefine industrial efficiency.

Machine Monitoring

Get a Free Product Tour

Reliable sensors to monitor your machines

Track machine status, downtime, and line event data from your machines, CNCs and production cells with state-of-the-art IOT sensors.

Enable operators and set records every shift

Define production goals, reproduce what works with best practices for setup and adjustments, and have your team working like a team.

Increase On Time Delivery

Track production count, manage demand surges, and keep deliveries On-Time, every time. Reduce returned orders, and increase First Pass Yield with digitized quality inspection.

Improve OEE at your shop floor

Use accurate metrics for calculating, tracking and reporting OEE and other core production KPIs.

Everything Starts With Reliable Data

Your Foundation for Reliable Factory Data. Quick to deploy, easy to scale.

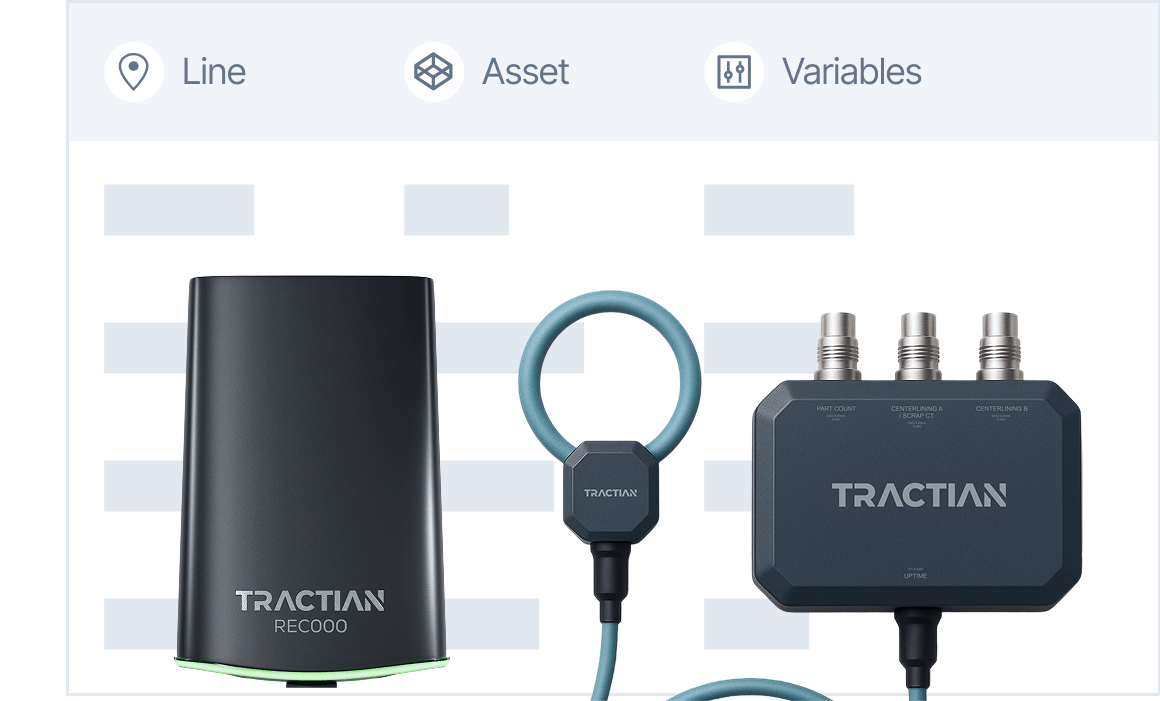

1. Universal machine connectivity

Connect to all your machines with industrial-grade proprietary IOT sensors that can tap into analog and digital inputs, current readings and PLCs ensuring full compatibility with your systems.

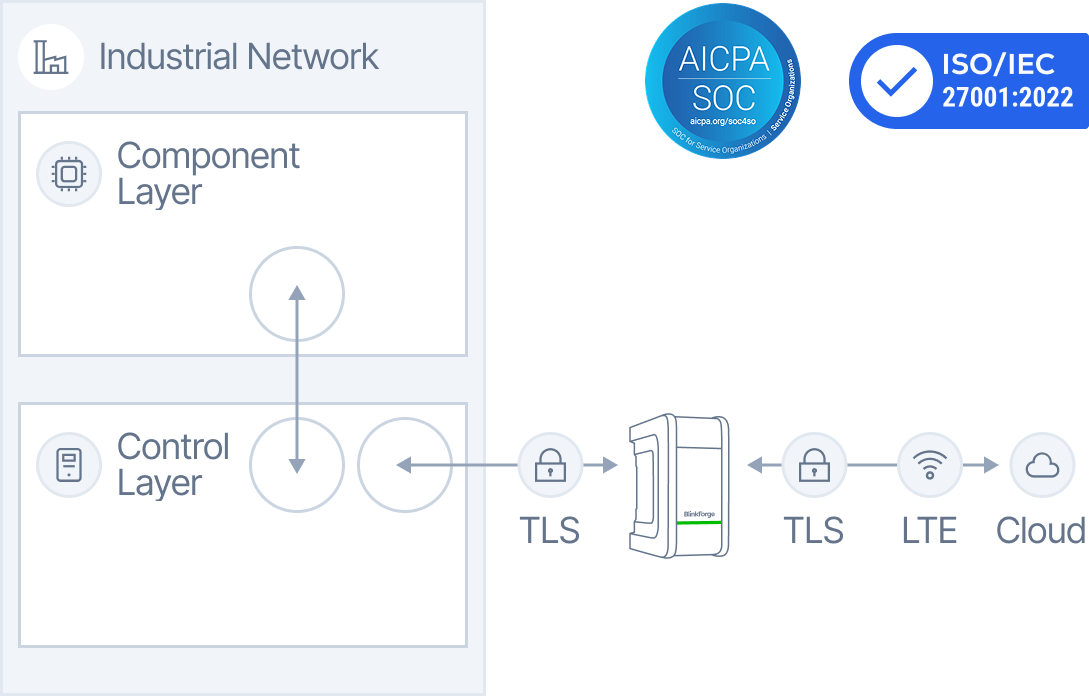

2. Clip-on sensors, easy installation

Easily clip-on our IoT sensors to begin transmitting real-time production data. Our hardware ensures data security, reliability, and uptime, backed by SOC 2 Type II and ISO 27001 certifications.

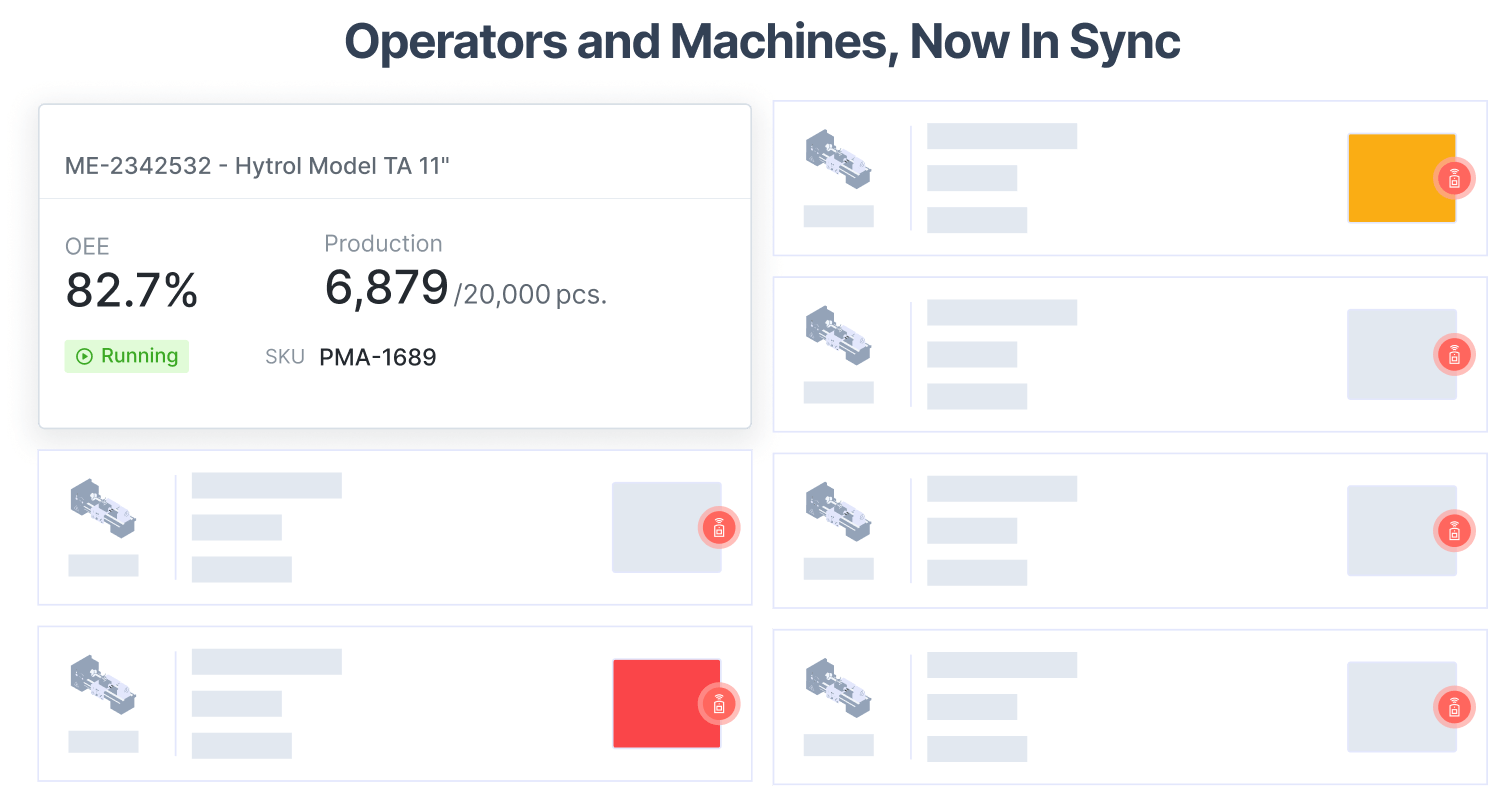

3. View the status of your machines

Utilize real-time analytics to monitor the status of your machines, track OEE, identify downtime causes, and discover hidden inefficiencies. Gain site-wide visibility at your fingertips.

OEE: Accurate, Front

and Center

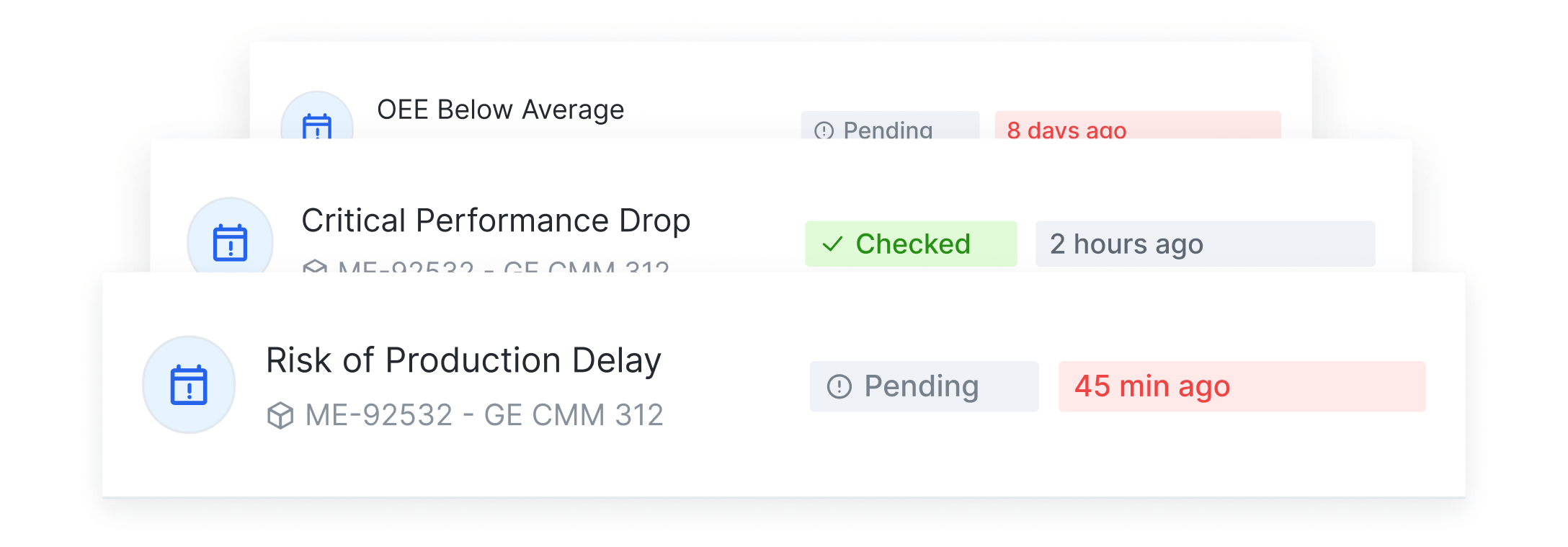

Fix the right problem, at the right time. Instantly flag inefficiencies, notify the right teams, and resolve bottlenecks before they impact output

Track OEE at a glance, spot trends, and take immediate action—all in a single system.

Powered by AI, to

keep you ahead

Our AI delivers the critical insights you need to stay ahead. Proactively identify the right problems, flag inefficiencies, and resolve bottlenecks using powerful predictive insights before they impact output. Instantly understand OEE, spot emerging trends, and take decisive action, all guided by intelligent data within one system.

Unlock the real power of your Operators

Unleash the full potential of your shop floor team. Operator View provides intuitive access to real-time data

and the tools to contribute critical input, transforming them into key drivers of efficiency and continuous

improvement on the shop floor.

Know the root cause of downtime, everytime

Close the loop on every downtime event. Empower your operators to instantly label downtime, guided by AI-powered suggestions for accurate root cause identification.

Real Collaboration, to help you win shifts

Supercharge team collaboration with FactoryChat™, your shop floor's instant communication channel. Seamless information sharing, rapid problem-solving, synchronized efforts.

Digitized Quality, to achieve your best FTY

Increase First Time Yield and reduce returns through operator-led digitized quality inspections. Empower your with rich, customizable procedures to log quality at the factory floor.

Don't take our word for it.

See what our customers have to say

Trusted by US and global manufacturers

Leading manufacturers in the US and worldwide choose Tractian for reliable solutions that enhance

efficiency and drive growth on the factory floor.

Get started today.

Get your production on track with Tractian OEE™