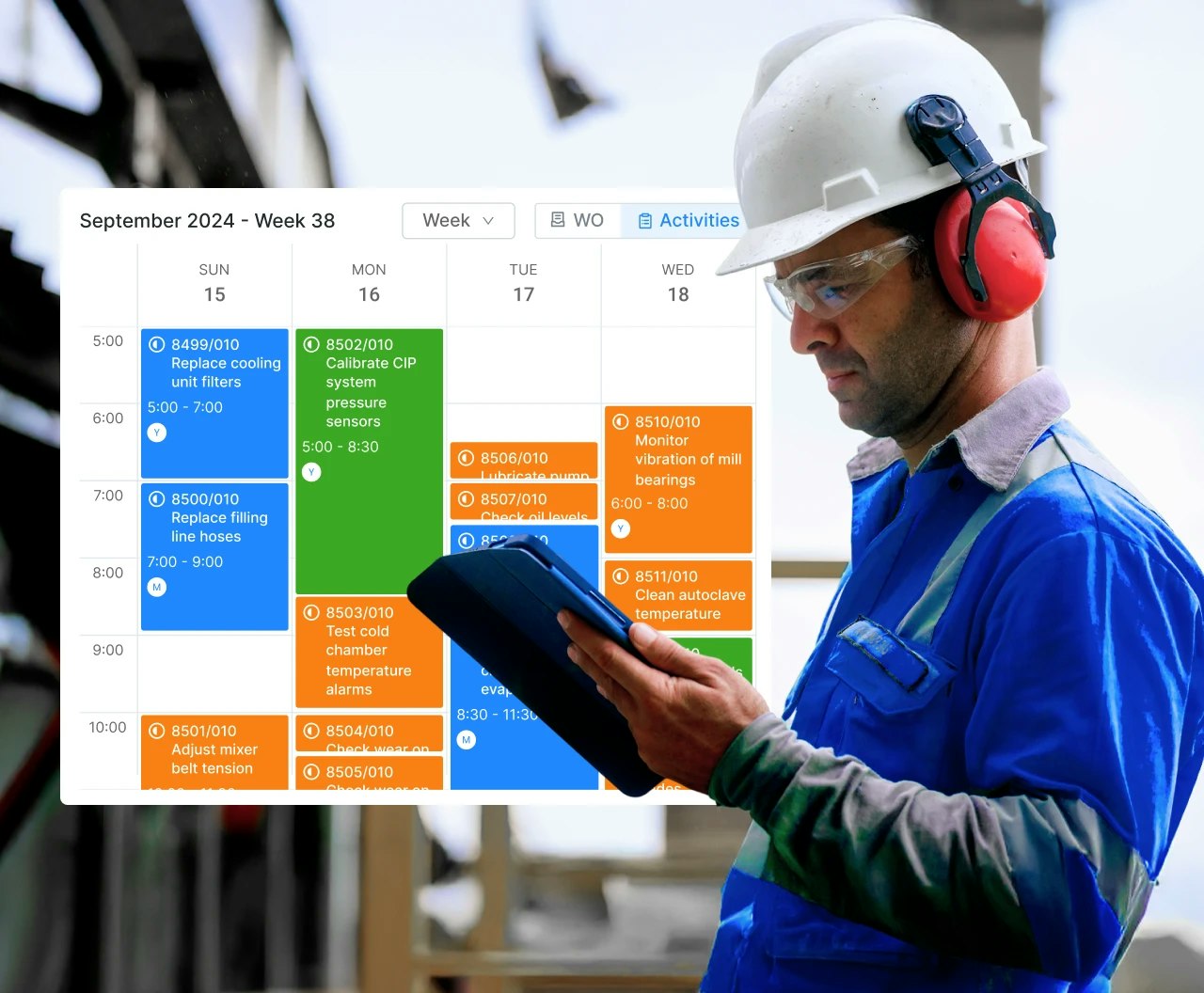

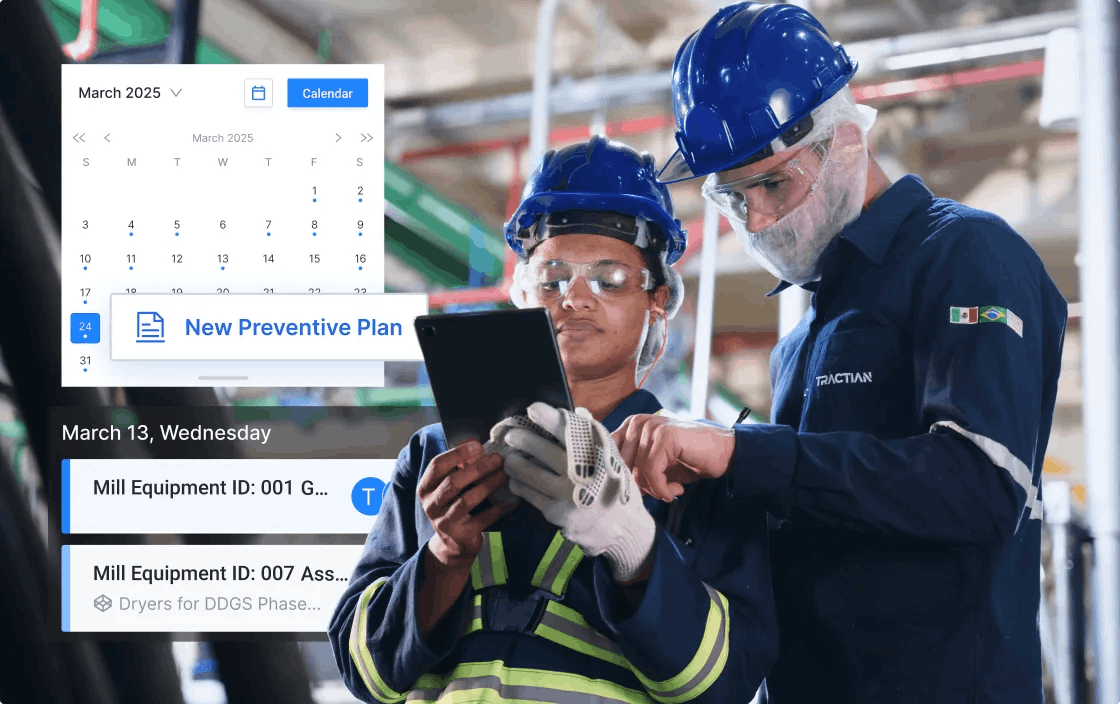

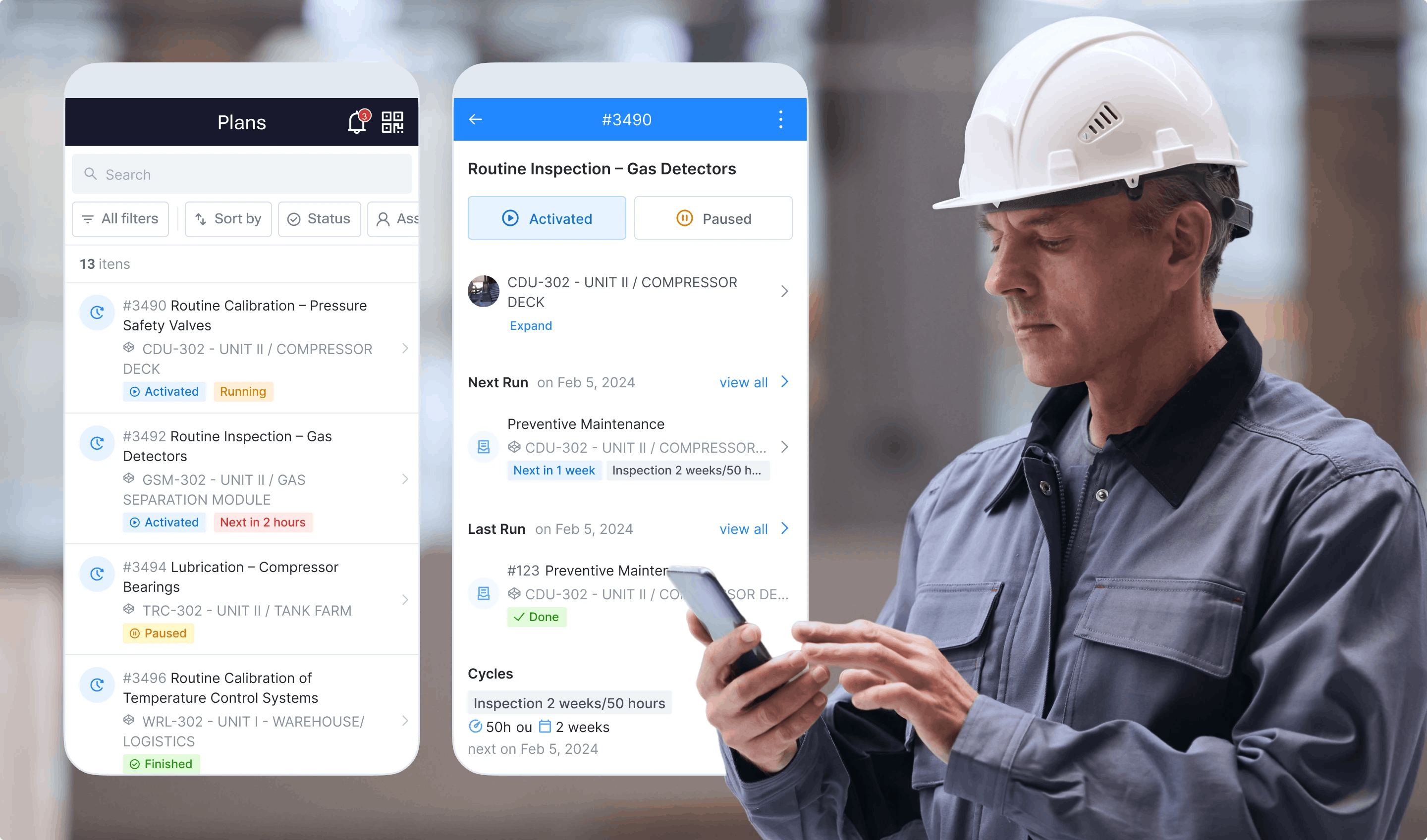

AI-POWERED PREVENTIVE MAINTENANCE SOFTWARE

Proactive plans to reduce downtime and catch failures

From reactive to proactive maintenance: build, automate, and track your PM plans, all in one tool. Tractian CMMS helps you schedule tasks, monitor compliance, and catch failures before they happen.