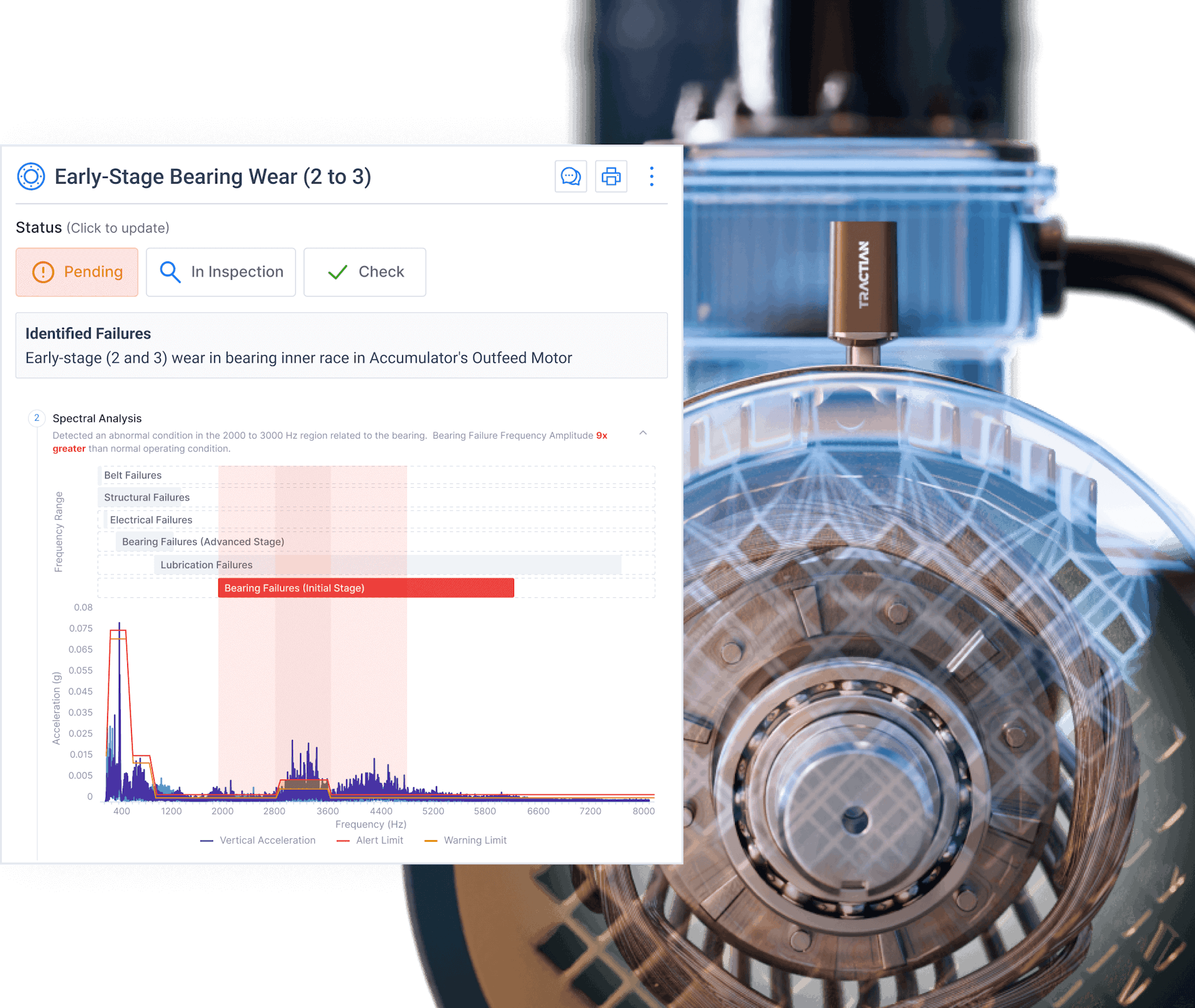

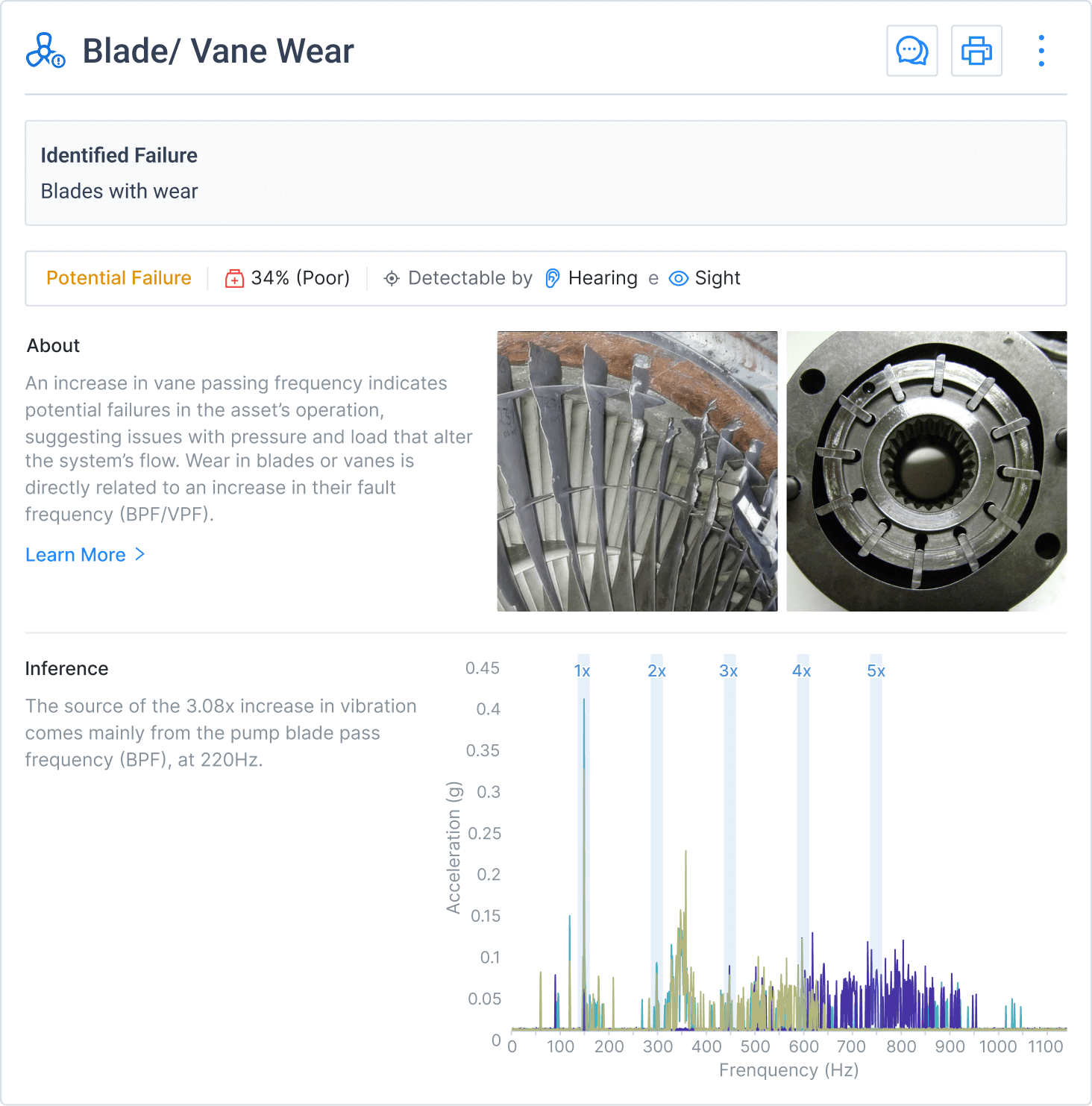

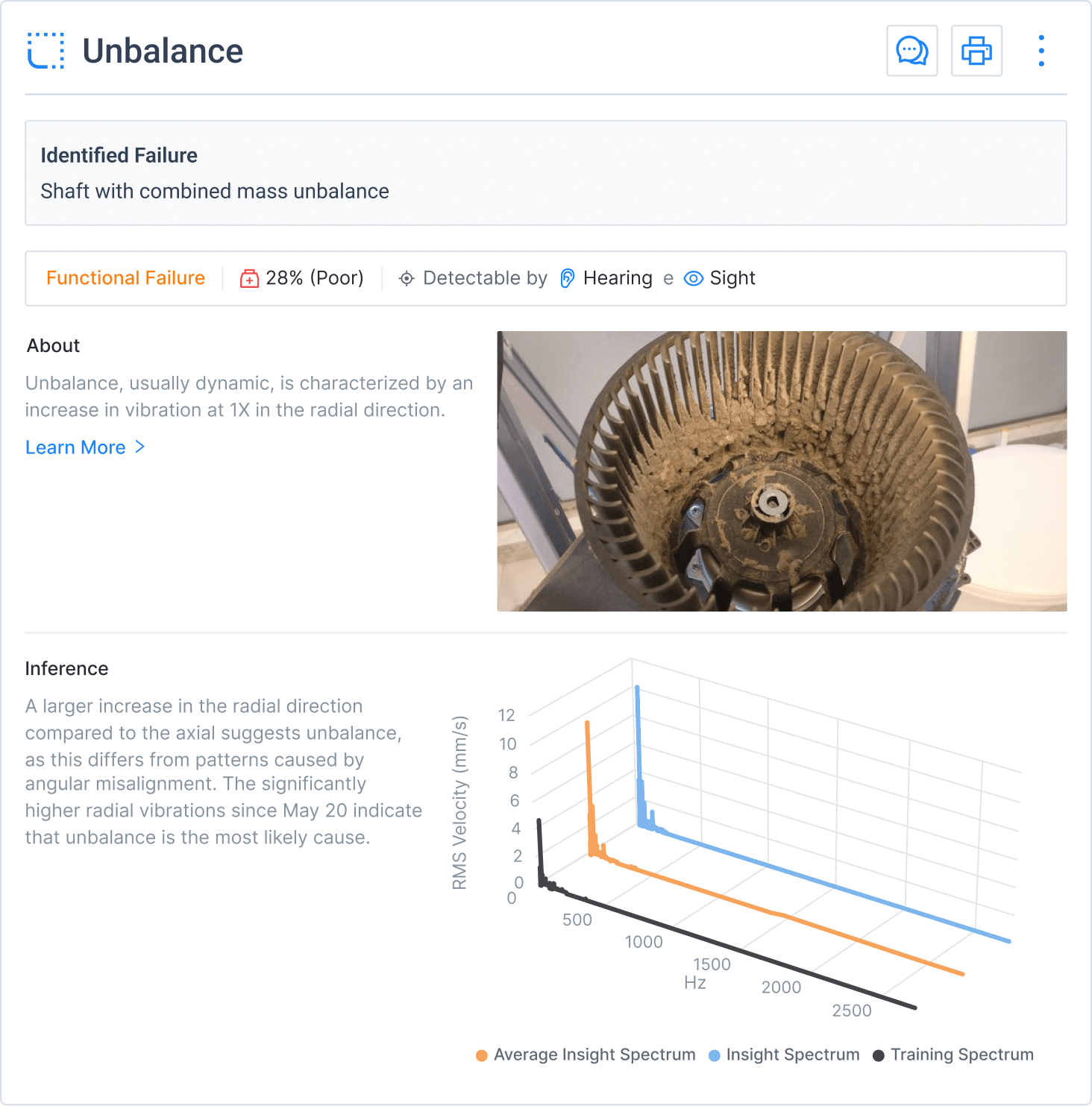

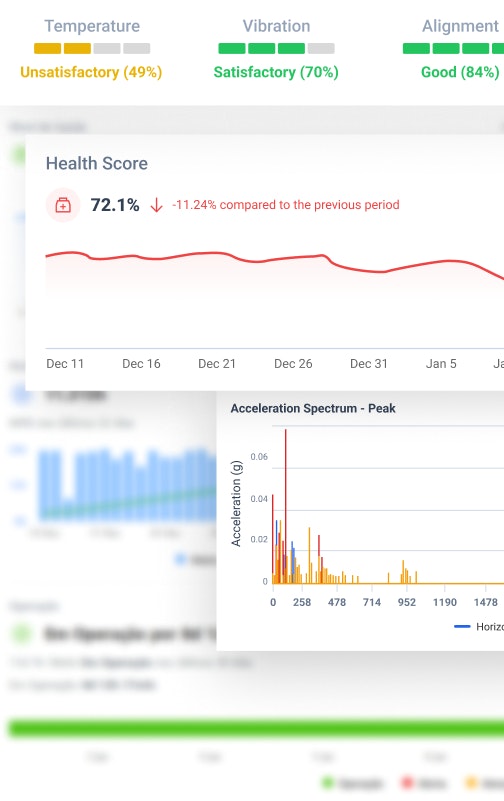

FROM DATA SAMPLING TO COMPREHENSIVE SOLUTIONS

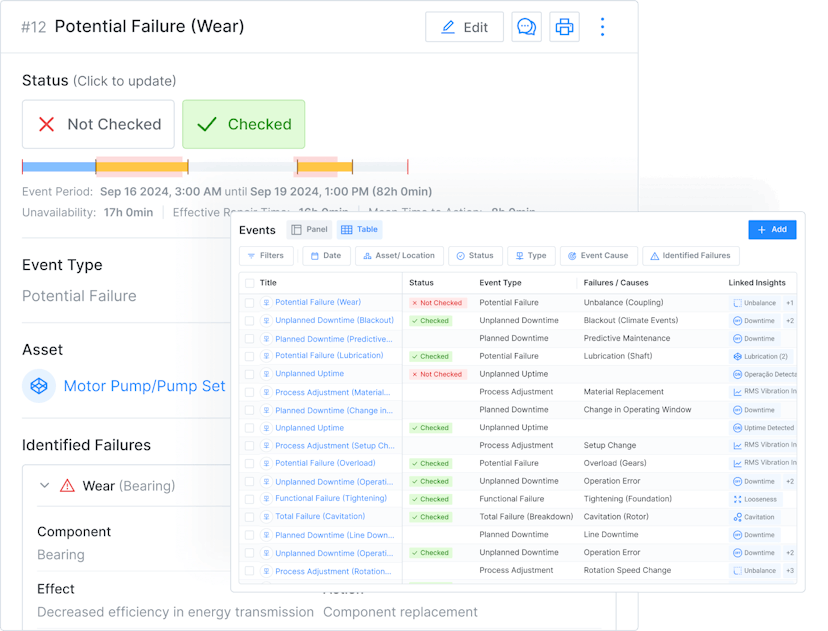

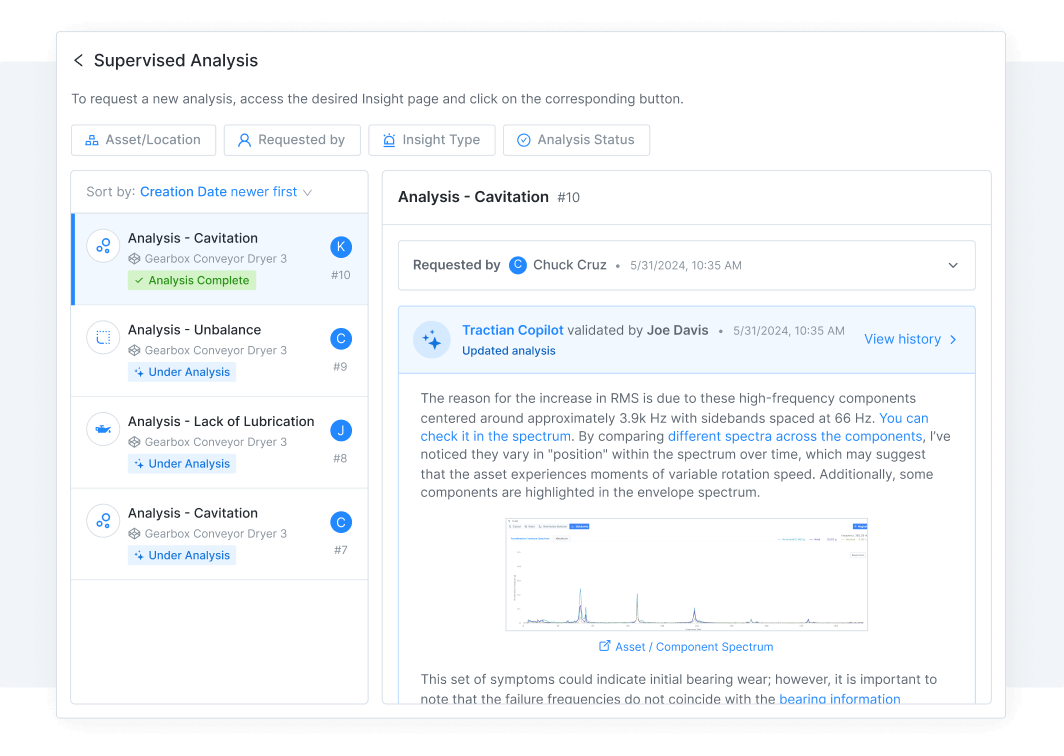

Condition Monitoring Insights

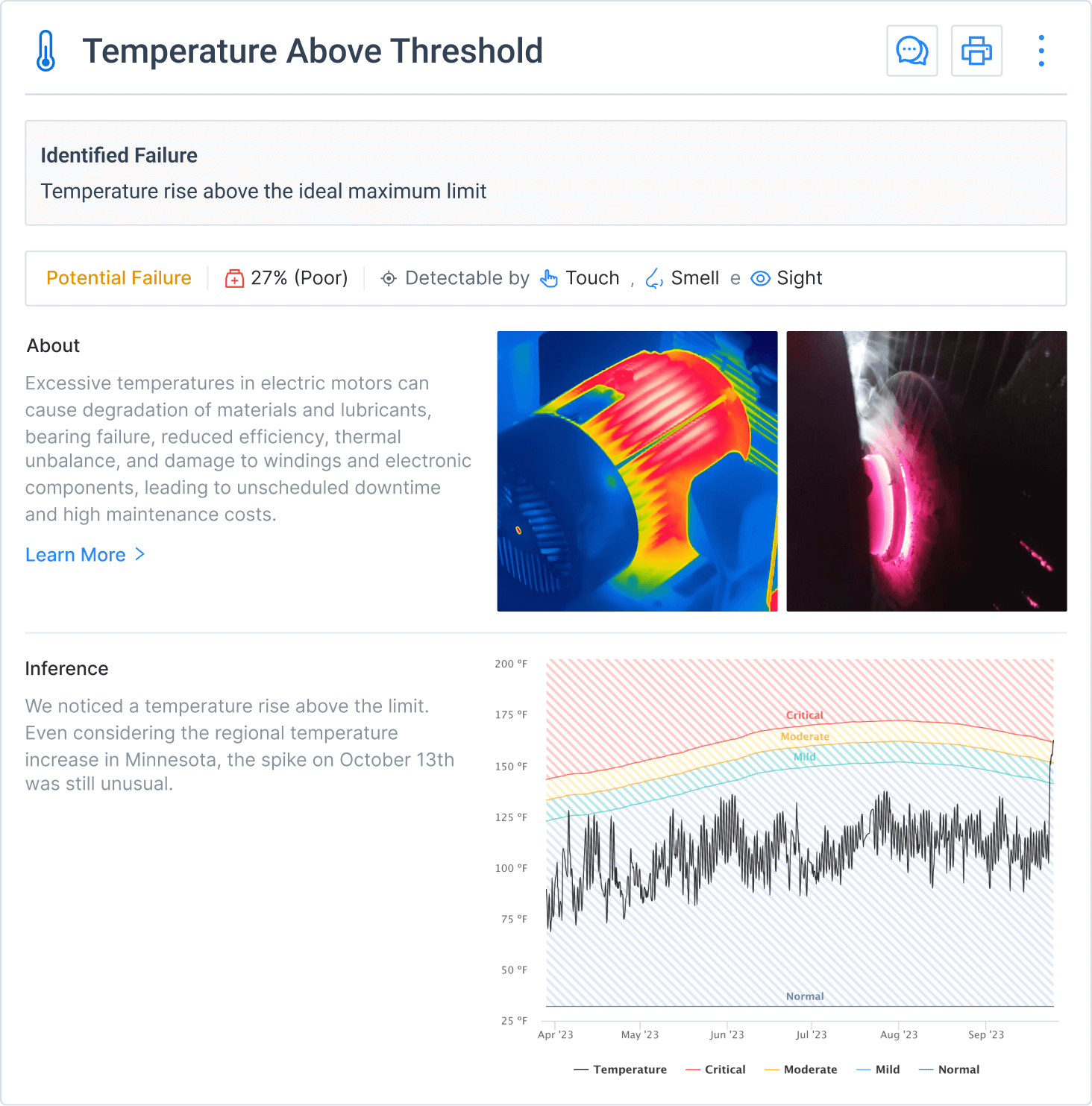

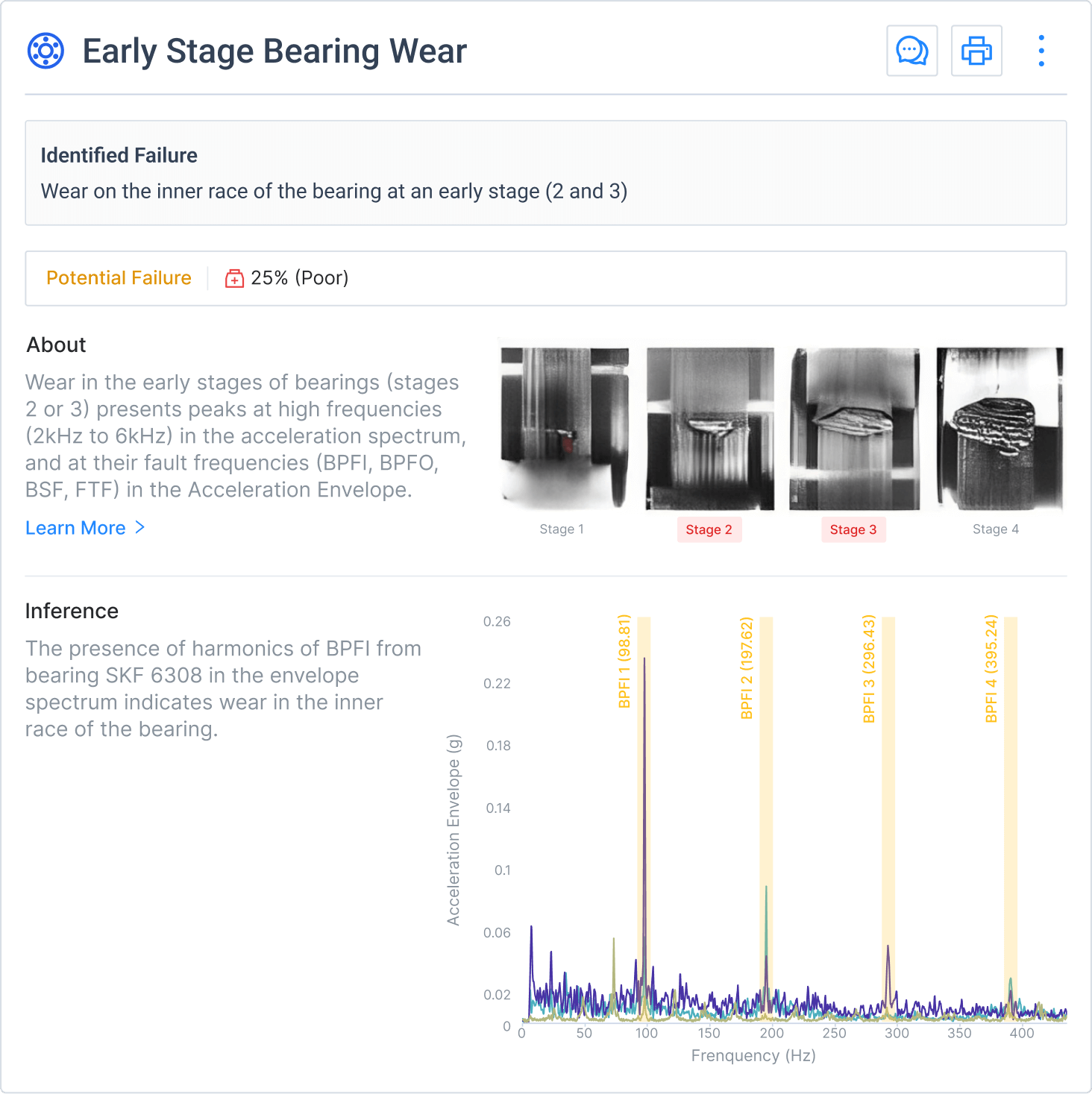

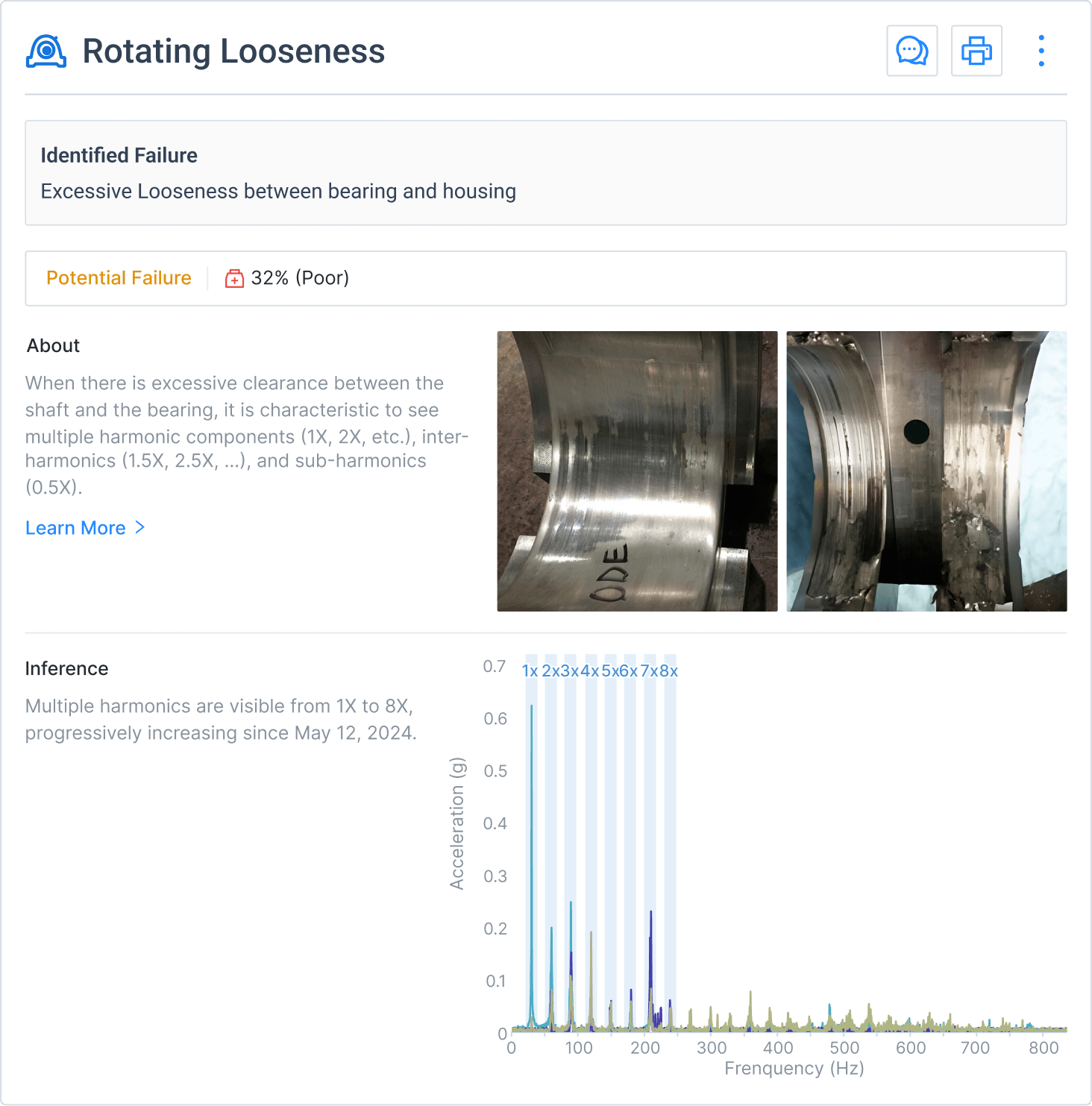

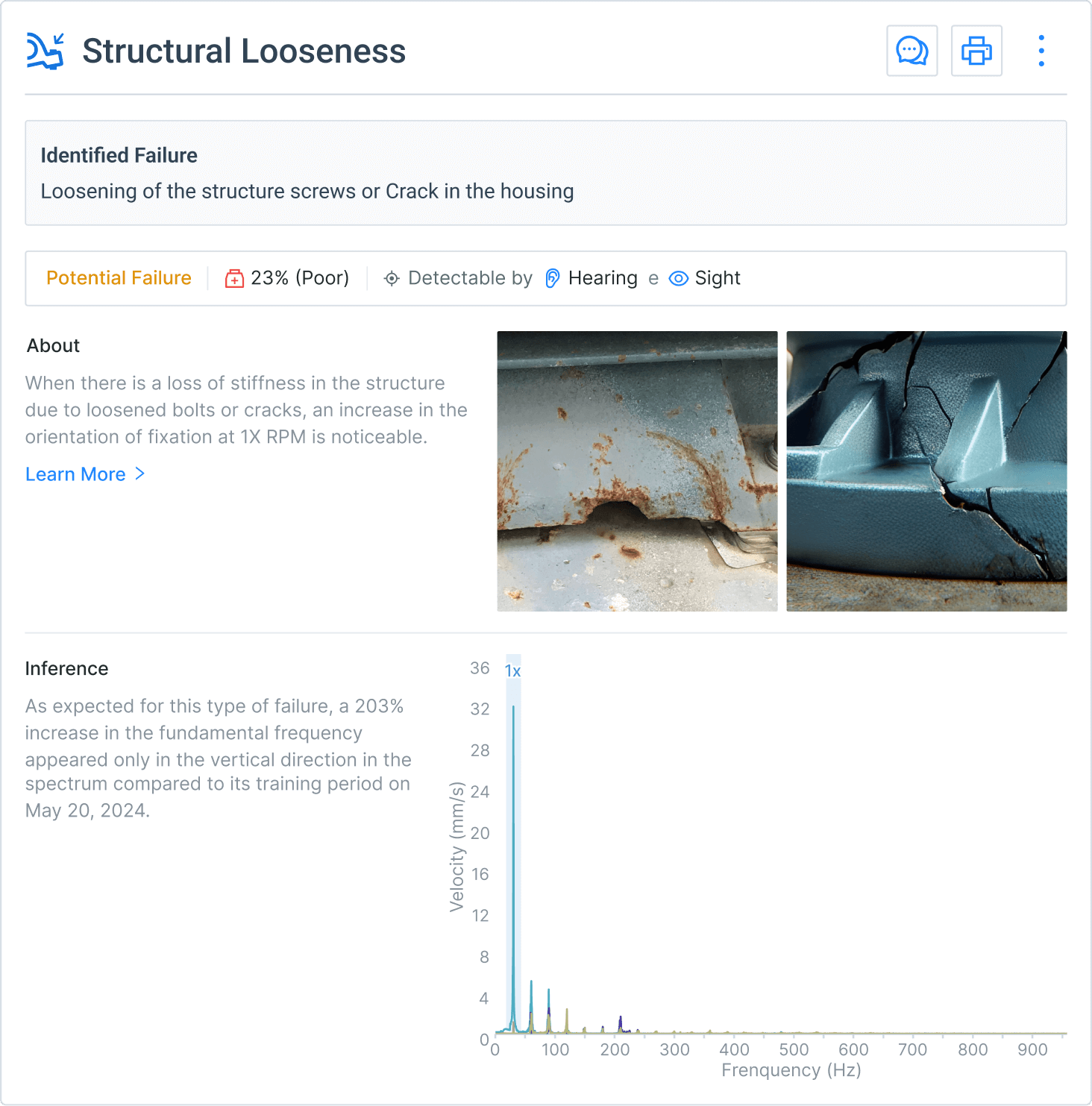

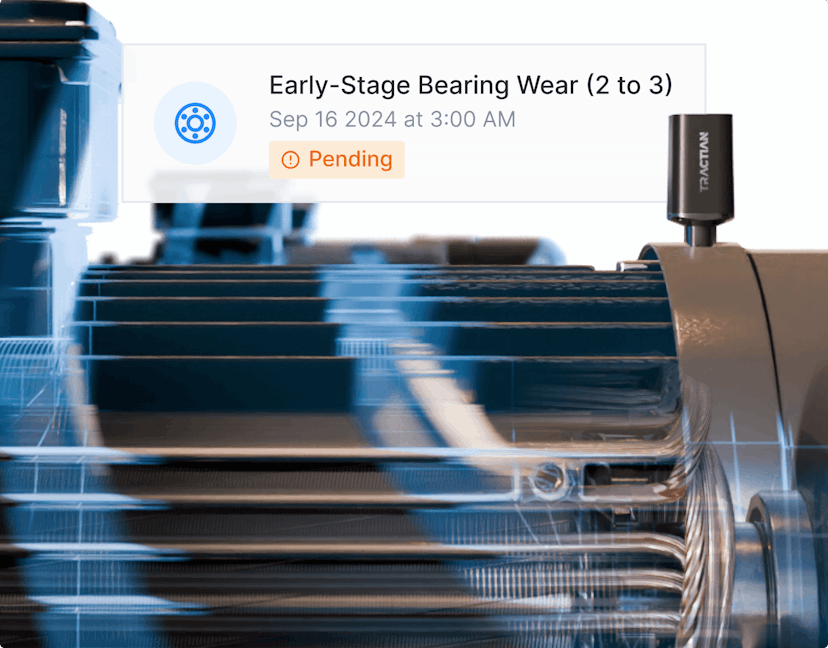

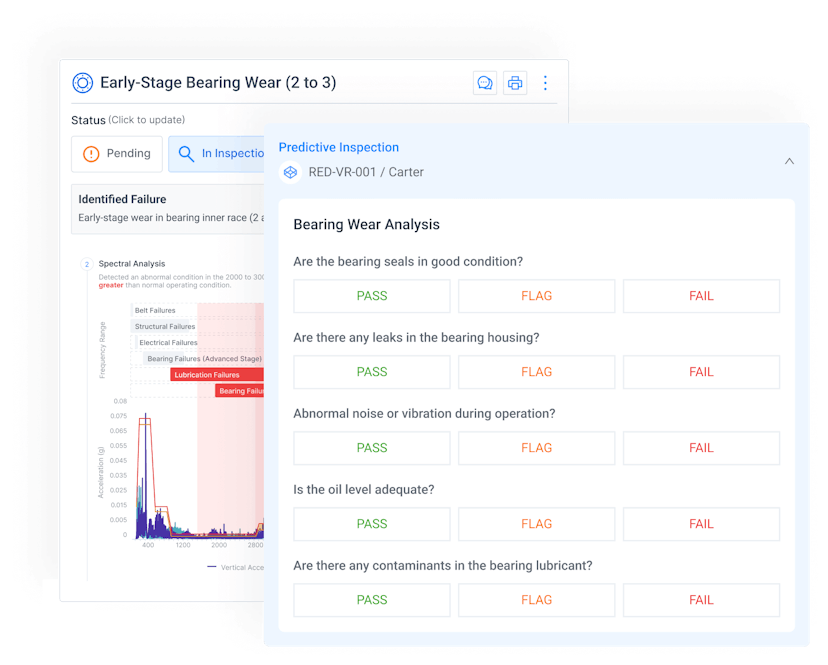

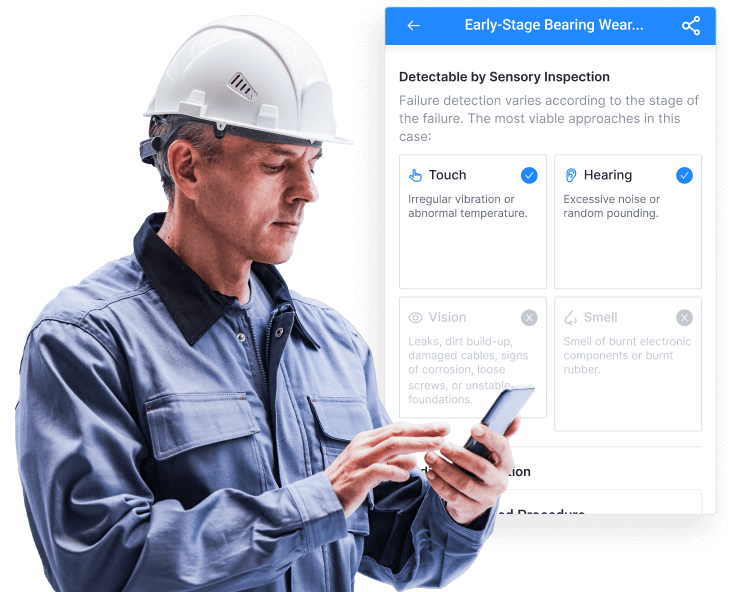

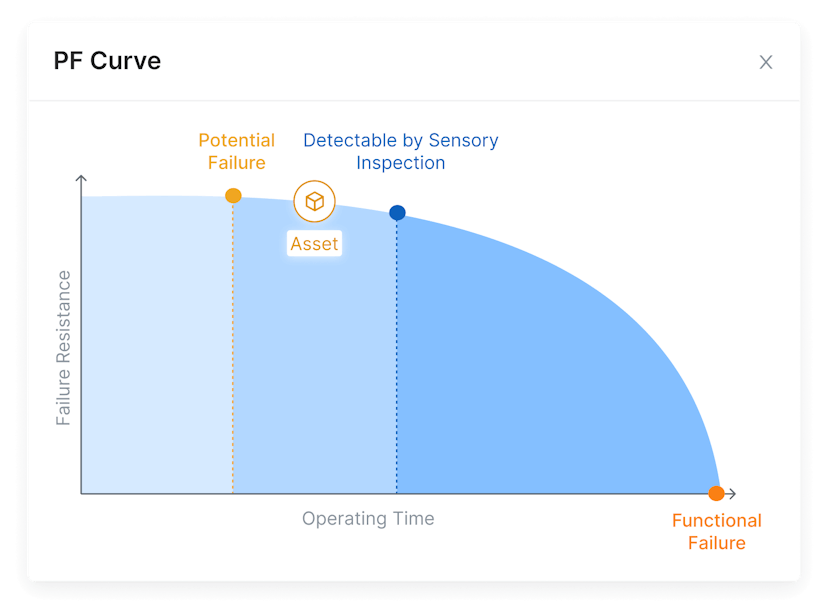

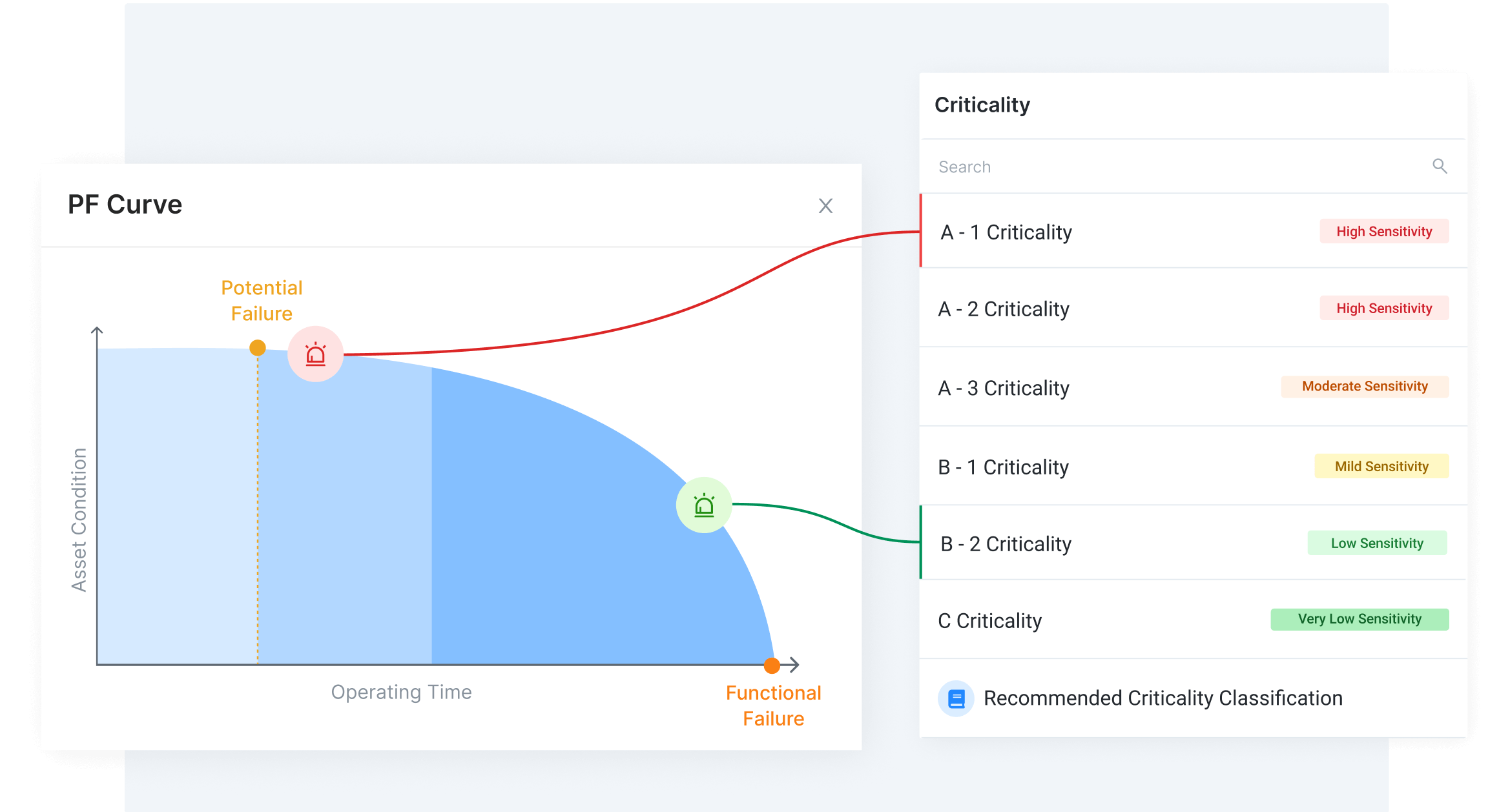

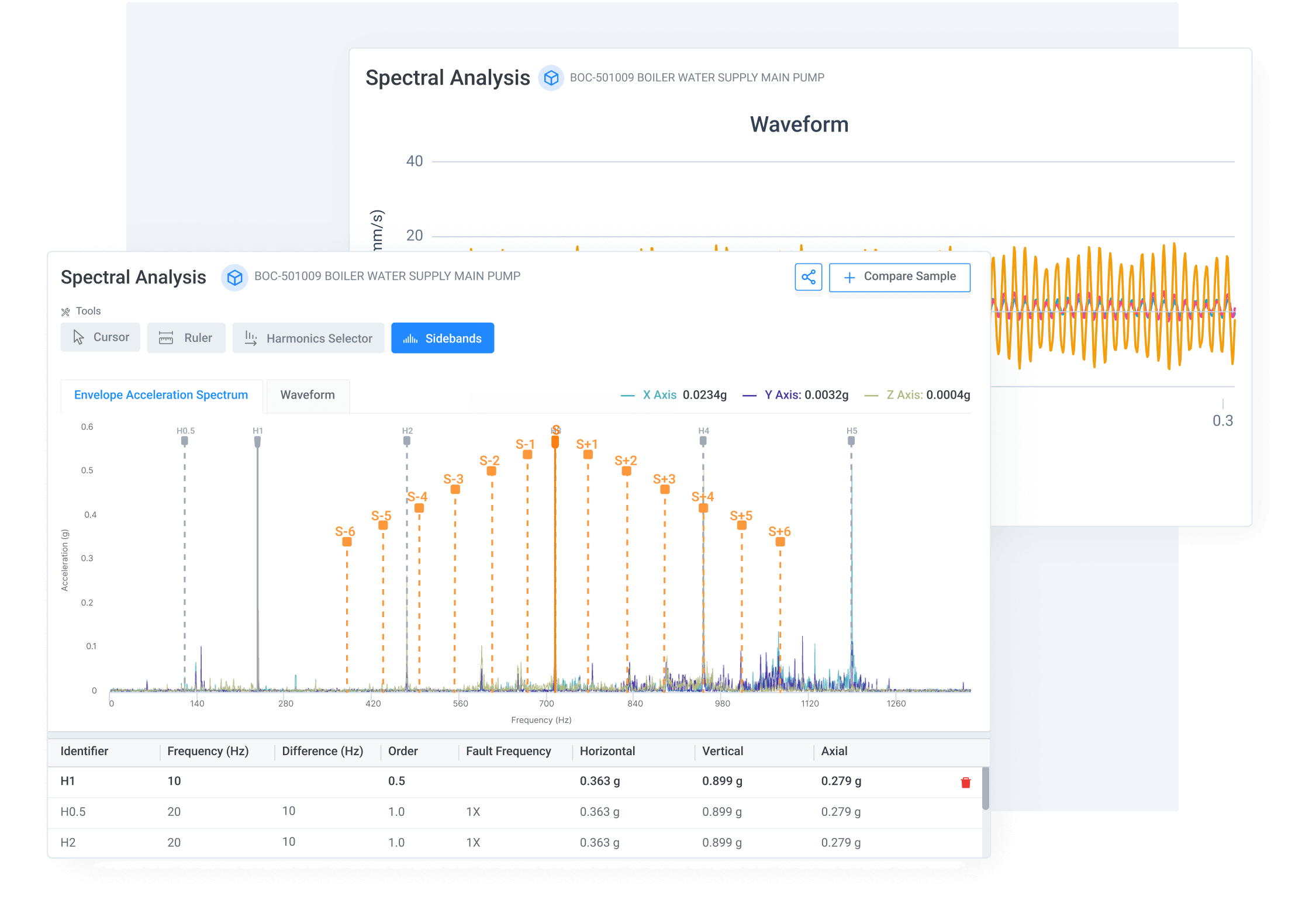

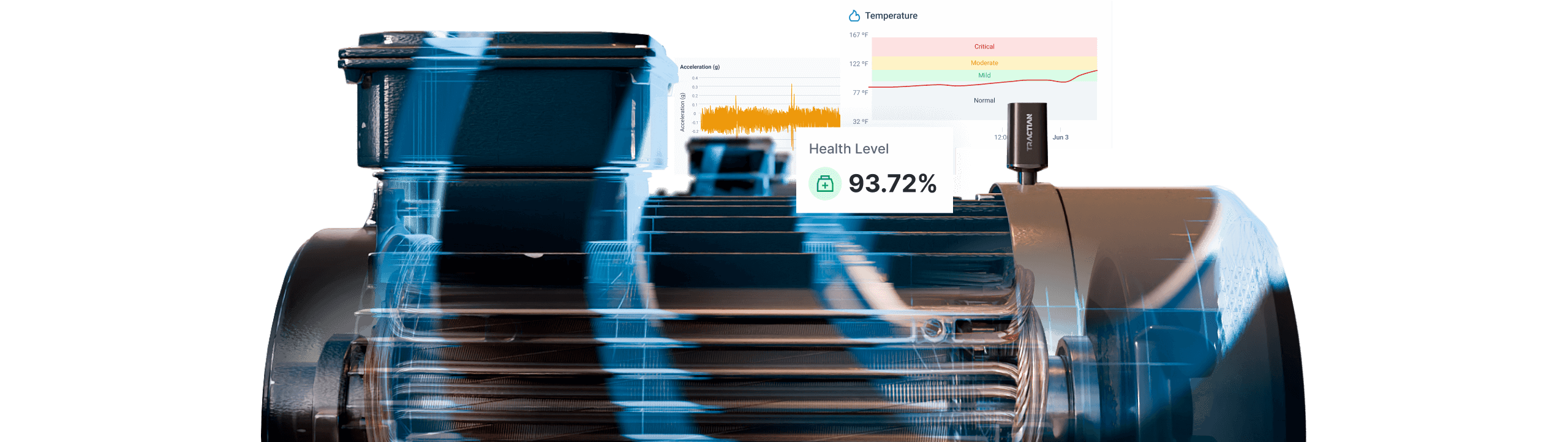

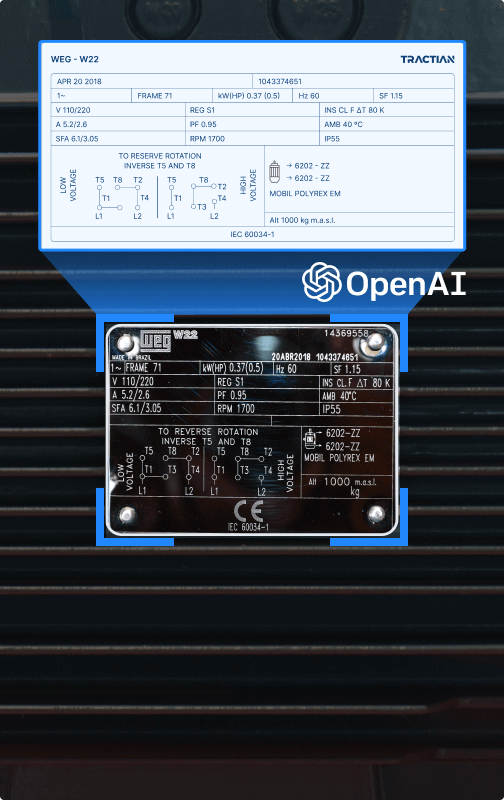

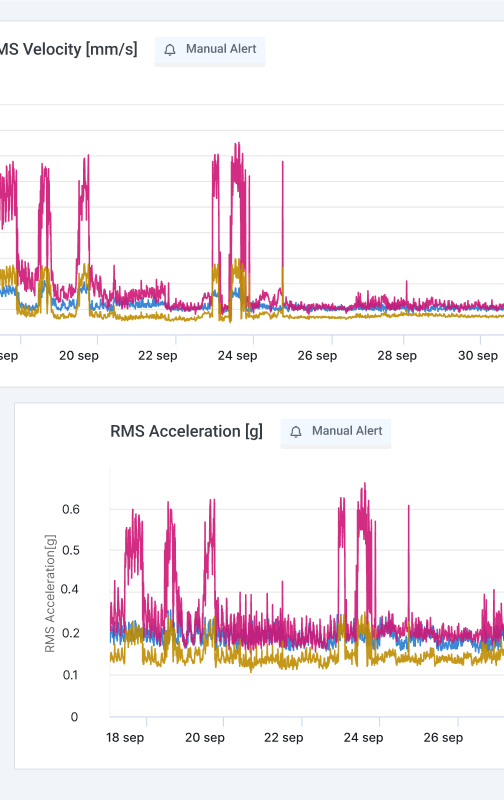

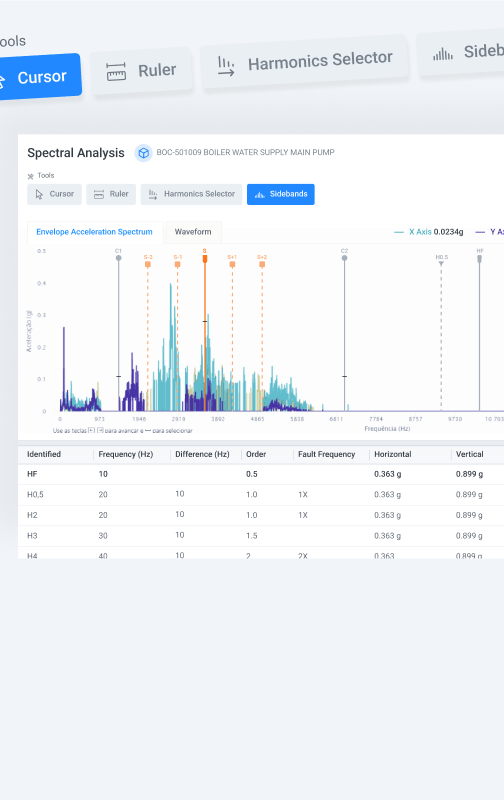

Our system samples and analyzes vibration, temperature, runtime, and RPM data in real time, delivering insights based on the criticality of each asset. With our integrated AI, you get assisted diagnostics and recommendations on how to fix issues quickly.