Engineered for reliability

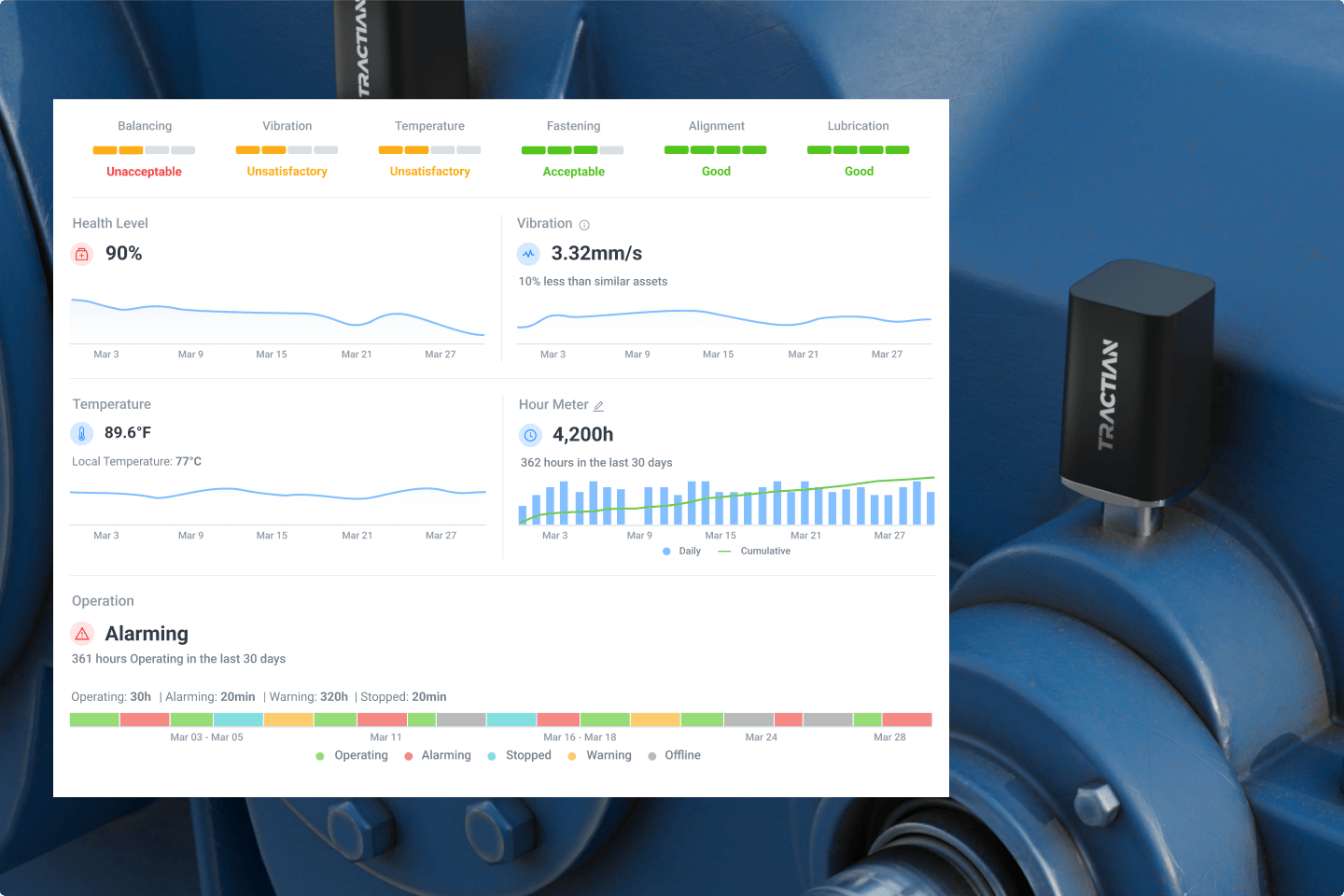

The TRACTIAN sensor monitors vibration, temperature, runtime, and RPM data in real time, and is equipped with Fault-Finding Auto Diagnosis™ to detect and diagnose issues before they become critical.

The TRACTIAN sensor monitors vibration, temperature, runtime, and RPM data in real time, and is equipped with Fault-Finding Auto Diagnosis™ to detect and diagnose issues before they become critical.

Watch the Deep Dive

*Based on a survey of 200+ companies with extended experience using TRACTIAN.

Return on Investment (ROI)

Availability after Implementing TRACTIAN Condition Monitoring

Reduction in Downtime

*Based on a survey of 200+ companies with extended experience using TRACTIAN.

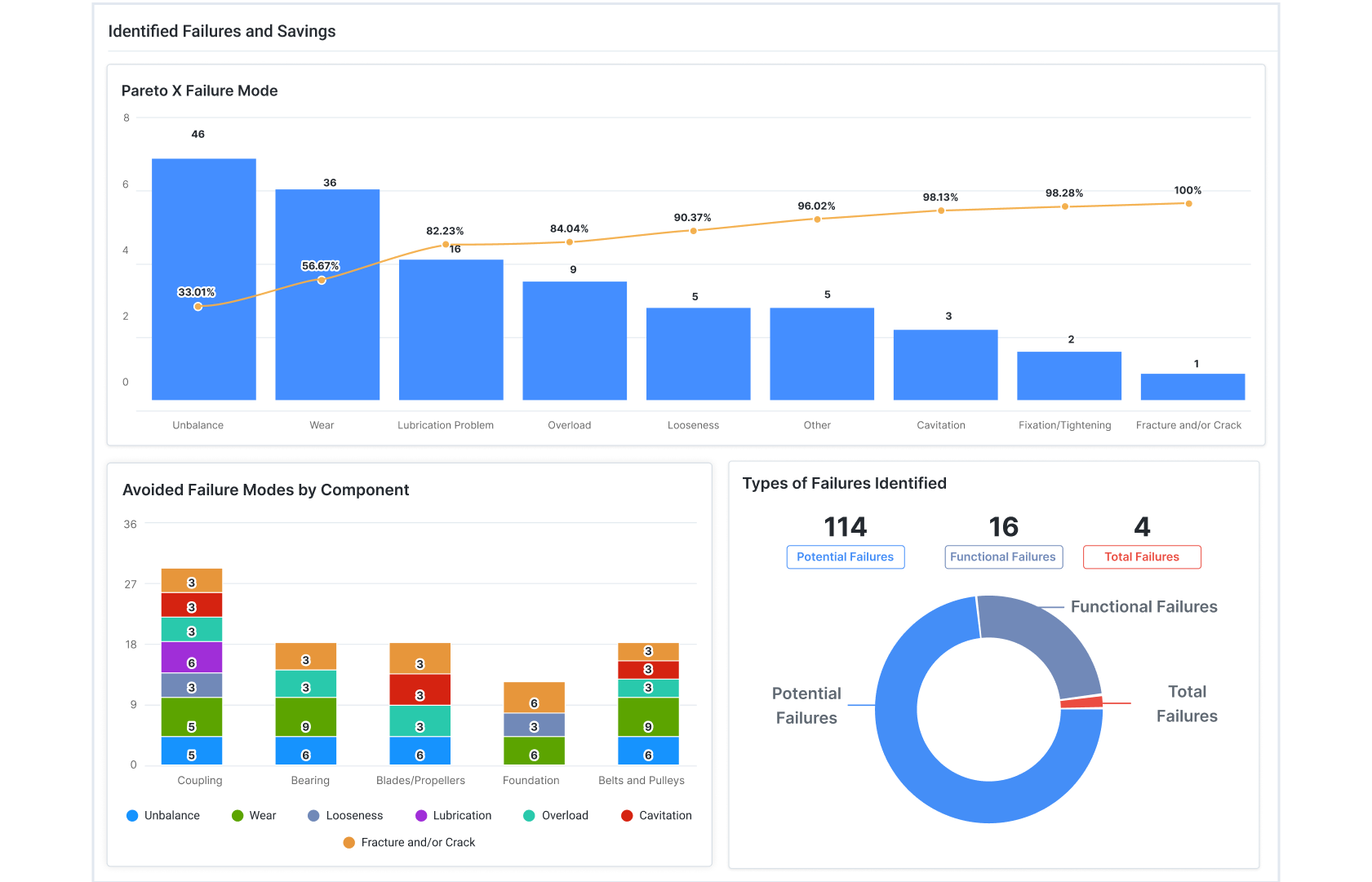

Our solution detects a wide range of failure modes, prioritizing critical issues. By eliminating unnecessary inspections, your team can focus on what truly matters: ensuring operational continuity.

Fault detection and Auto Diagnosis™ serve as a base for data-driven reports and dashboards, which pinpoint identified failures, savings, and avoided downtime.

Failures

Savings

Avoided Downtime

Machine data goes through a three-layer comparative analysis to benchmark the asset against competitors from all across the world.

• Self-Analysis: Compares performance against its own history

• Intra-Company Benchmarking: Measures against similar assets in the company

• Industry-Wide Comparison: Benchmarks against assets across industries

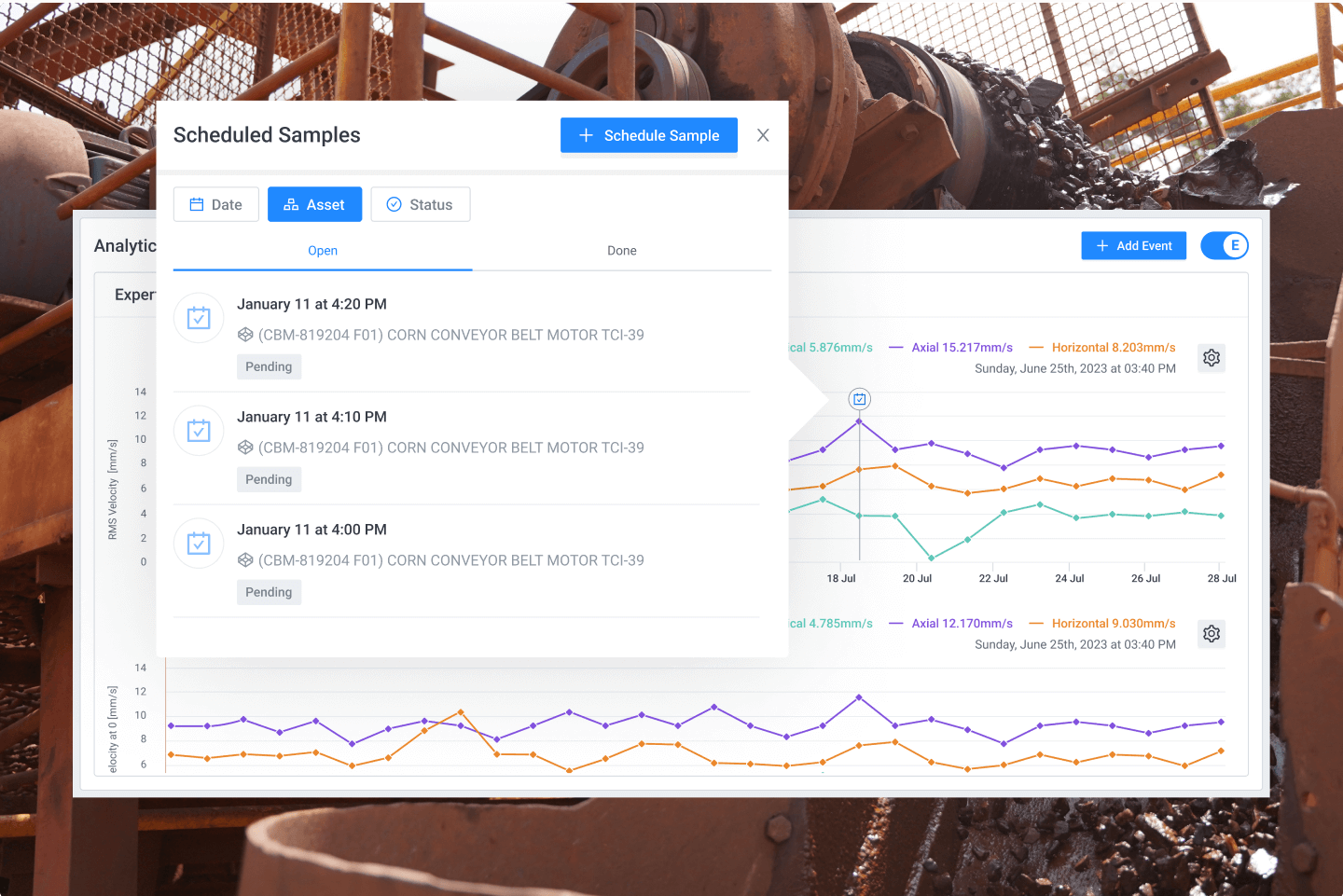

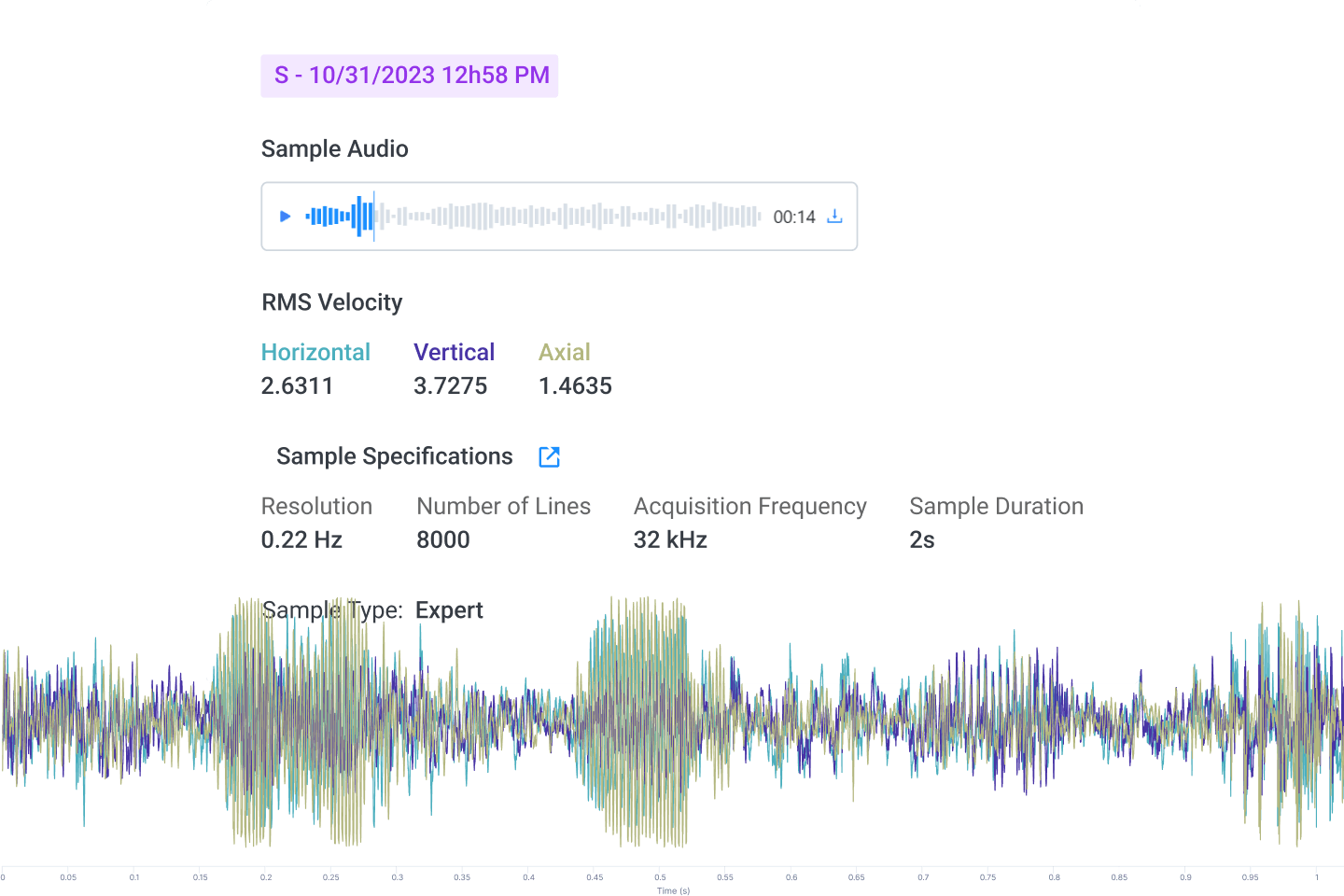

Personalize sample profiles according to your companys needs:• Trend Sample • Expert Sample • Auto Diagnosis™ Sample

• Check the status of indicators like Alignment, Balancing, Temperature and more — all in a single screen • Keep up with failure trends before being alerted by an insight

• Transform a spectrum into audio to hear and interpret the real sound issued by the machine

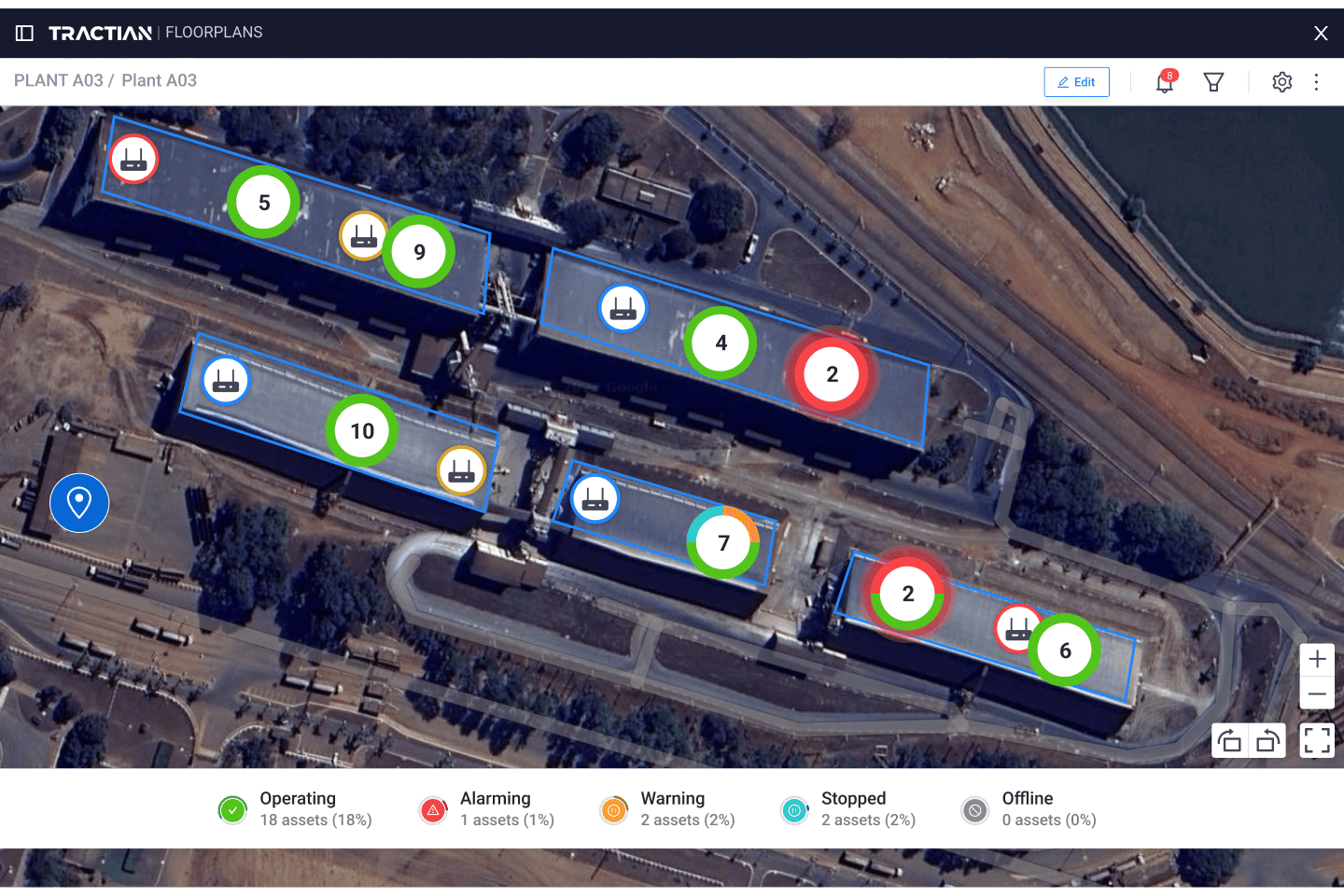

• Keep up with all assets and locations at once with the TRACTIAN-exclusive Floorplans feature

The power of AI in the hands of engineers, reliability experts, and maintenance professionals, providing them with continuous insights to improve asset performance.

Smart Trac Ultra continuously monitors machine condition to detect and diagnose 70+ failure modes, cut maintenance costs, and eliminate unplanned downtime.

Data from America's leading companies is combined with our reliability expertise for accurate historical trend and competitor comparison analyses.

From 0 Hz to 32000 Hz

Up to 16 g

Up to 100 mm/s RMS

From -40°F to 250° F (-40°C to 120°C)

32768 lines (per axis)

Samples every 5 minutes

500Hz (64s), 1000 Hz (32s), 2000 Hz (16s), 4000Hz (8s) , 8000Hz (4s) 16000Hz (2s), 32000Hz (1s)

915MHz ISM

IEEE 802.15.4g

LTE/4G mobile networks, with no need to rely on industrial Wi-Fi

6 frequency channels, dynamically assigned

Up to 330ft (100m) between sensor and receiver, depending on the industrial plant topology

Up to 3,300ft (1km) between sensor and receiver, depending on the industrial plant topology

40 (W) x 71 (H) x 40 (D) mm or 1.6 (W) x 2.8 (H) x 1.6 (D) in, excluding sensor base

180g / 6.4 oz (sensor) 22g / 0.8oz (shorter base) 50g / 1.75oz (taller base)

Lexan™

Sensor base must be glued or screwed to the asset

100% Resin Coated

Encrypted AES (128 bits)

FCC

IP69K

Suitable for installation in high humidity areas

From -40°F to 250° F (-40°C to 120°C)

Complies with ATEX, NFPA 70 CL1, CL2, and CL3 (All Division I).

Lithium battery

Between 3-5 years on default settings

Temperature, transmission distance, and data acquisition configuration