3 min.

TRACTIAN Video Library

6 min.

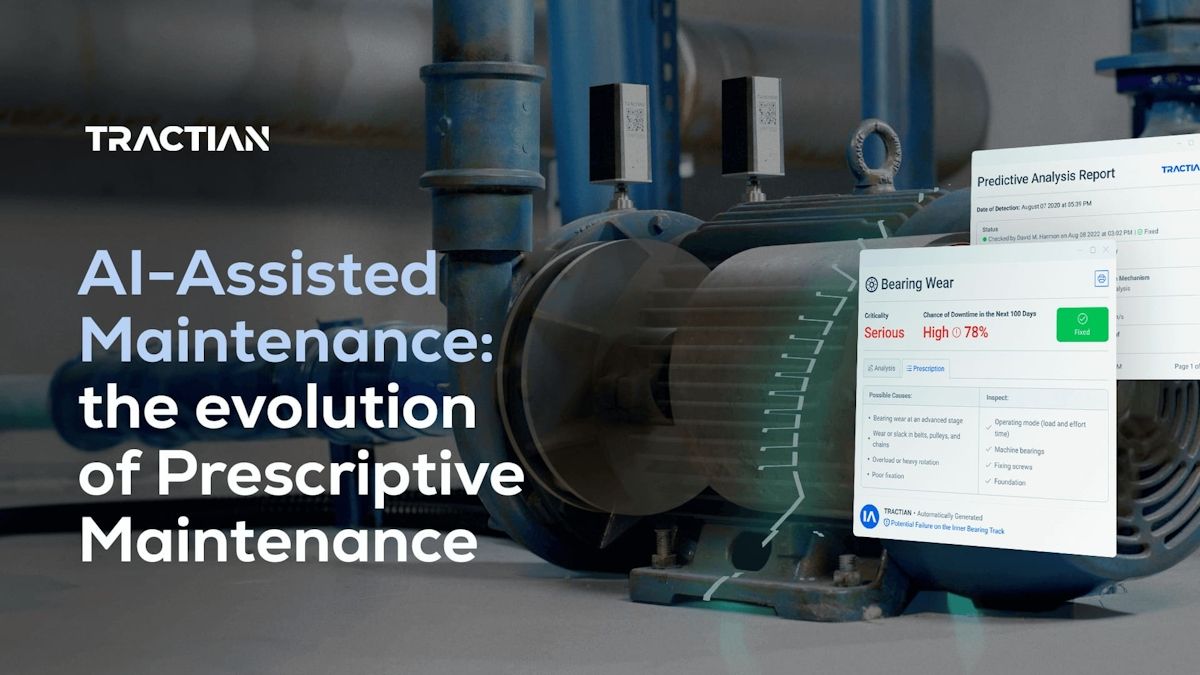

2 min.

- Extreme durability: Built to withstand temperatures from -40°F to 230°F

- Hazardous Locations ready: ATEX, IECEx and Division 1 certified for maximum versatility

- Unparalleled accuracy: CNC-machined base and integrated thermistor for precise temperature data

- Wireless communication: 915 MHz connectivity with 4G/LTE support and 3,300 ft line-of-sight range

- Scalable monitoring: One Smart Receiver Ultra can handle up to 100 sensors simultaneously

5 min.

6 min.

- Automatic PM scheduling and remote work order management

- Automatic generation of maintenance KPIs such as MTBF, MTTR, Availability and Reliability

- Work requests opened remotely using QR codes

- Real-time communication via the built-in chat

- Being able to take the software anywhere with you with Tractian mobile app, enabling complete mobility, even in no-service areas

3 min.

2 min.

3 min.