TRACTIAN AI-POWERED CMMS SOFTWARE

AI-Powered

Prevent failures, optimize operations, and streamline maintenance with Tractian CMMS.

AI-Powered

Prevent failures, optimize operations, and streamline maintenance with Tractian CMMS.

Guided support. 14-day trial.

OFF-HIGHWAY

MILLS & AGRICULTURE

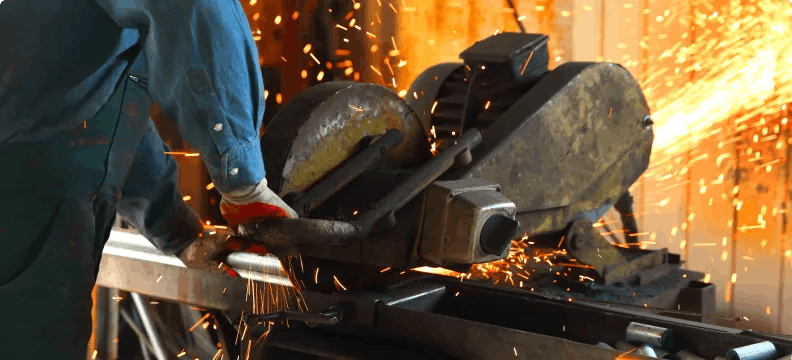

METAL-MECHANICS

RETAIL

FOOD & BEVERAGE

AUTOMOTIVE

CHEMICAL

FACILITIES

Get started in minutes with a simple onboarding experience. Easily import all your data from spreadsheets or other systems using our Import Tool.

Fast ramp-up, zero hassle. Minimal training required thanks to a simple interface and a user-friendly software and mobile app.

Help from real experts - any time you need it. Our team of maintenance pros is always on hand, backed by a full library of tutorials and our own training platform.

FAQ

Can't find what you're looking for? Our sales team is ready to help at +1 (833) GET-TRAC

Your feedback is invaluable, that's why we are always open to discussing your needs. Feel free to contact us at any time if you need help. We are happy to chat.

Whether you're firefighting or forecasting, Tractian fits your workflow.

Plug-and-play platform

Easy setup and data import.

Free sandbox.

No credit card required.

One-click upgrade

Add new team members anytime.