Energy efficiency is an increasingly crucial issue for industries, not only because of the need to reduce costs, but also for sustainability and compliance with regulations.

If you are an energy manager, maintenance technician or professional responsible for optimizing energy consumption in your industrial plant, this comprehensive guide is for you.

We'll cover in detail the concept of industrial energy efficiency, its importance and the best practices for achieving it. You'll learn everything from management strategies to the use of advanced monitoring and control technologies, such as TRACTIAN's Energy Trac.

What is Industrial Energy Efficiency?

Investing in industrial energy efficiency boosts profitability while showcasing a company's dedication to sustainability. Strategic energy management is now essential for staying competitive in today's manufacturing landscape. Discover how embracing energy efficiency can transform your business.

Download Free Electrical Work Order

What is Industrial Energy Efficiency

Industrial energy efficiency refers to the technologies, processes and practices used to reduce the amount of energy required for manufacturing and industrial operations. The goal is to optimize energy consumption, lower costs, and minimize greenhouse gas emissions while maintaining or improving productivity.

Key aspects of industrial energy efficiency include:

- •

Using energy-efficient equipment like motors, pumps, compressors, and HVAC systems

- •

Implementing automation and control systems to optimize processes

- •

Recovering waste heat and converting it to usable energy

- •

Integrating renewable energy sources into operations

- •

Conducting energy audits to identify opportunities for improvement

Adopting these practices can yield substantial benefits beyond just energy and cost savings. Improved equipment performance, shorter process cycle times, reduced maintenance needs and an enhanced public image are some of the many advantages of pursuing industrial energy efficiency.

In the next section, we'll dive deeper into the specific benefits that manufacturers can realize by making their operations more energy efficient. From boosting profitability to increasing competitiveness, the advantages are numerous and impactful.

Benefits of Improving Industrial Energy Efficiency

Improving industrial energy efficiency is a smart investment that pays off in numerous ways. By optimizing energy use, manufacturers can enjoy a range of compelling benefits that boost their bottom line, enhance their market position, and contribute to a healthier environment. Let's explore some of the key advantages of adopting energy-efficient practices and technologies:

Lower Energy Costs

By reducing energy waste and optimizing consumption, companies can significantly cut their utility expenses. Even small improvements can translate to substantial cost savings over time.

Increased Competitiveness

With lower production costs from energy savings, manufacturers can improve profit margins and be more price competitive. Energy-efficient facilities also tend to be more productive and reliable.

Reduced Environmental Impact

Optimizing energy use helps shrink a company's carbon footprint and meet sustainability goals. This is increasingly important for attracting eco-conscious customers and investors.

Compliance with Regulations

Many governments are mandating stricter energy efficiency standards for industry. Getting ahead of these requirements avoids costly penalties and mitigation measures down the line.

The benefits of industrial energy efficiency are clear – from boosting profitability and competitiveness, to reducing environmental impact and regulatory risk. However, to fully realize these advantages, manufacturers need a strategic, comprehensive approach that optimizes energy across the entire organization.

Proven strategies and technologies can help industrial facilities improve energy performance and achieve their efficiency goals. In the next section, we'll explore effective ways to enhance energy efficiency, including energy audits, smart technologies, employee engagement, and fostering a culture of continuous improvement. By implementing these strategies, manufacturers can take control of energy consumption and position themselves for long-term success.

Strategies for Improving Industrial Energy Efficiency

Improving industrial energy efficiency requires a multi-faceted, strategic approach. By implementing proven strategies such as conducting energy audits, upgrading equipment, utilizing renewable energy, and embracing circular economy principles, manufacturers can significantly reduce energy consumption and enhance sustainability. Let's explore some of the most effective ways to optimize energy use in industrial facilities:

Conduct an Energy Audit

The first step is assessing current energy use to identify waste and inefficiencies. Professional auditors use specialized tools (LINK TO ENERGY TRAC) to analyze consumption patterns and pinpoint savings opportunities.

Upgrade to Efficient Equipment

Replacing older equipment and installing high-efficiency alternatives can dramatically cut energy use. Options include variable-speed drives, LED lighting, high-efficiency HVAC, and heat recovery systems.

Implement Energy Management Systems

Automation platforms and digital tools provide real-time energy consumption data for individual assets and processes. This visibility helps optimize performance, detect waste, and make data-driven efficiency decisions.

Utilize Renewable Energy

Adopting solar, wind, geothermal or other renewables diversifies energy supply and reduces reliance on fossil fuels. Onsite renewable generation is increasingly cost-effective for industrial facilities.

Embrace Circular Economy Principles

Reusing waste streams as energy inputs, recycling materials, and sharing resources between industries creates a more sustainable manufacturing ecosystem.

How TRACTIAN's Energy Trac Enables Energy Efficiency

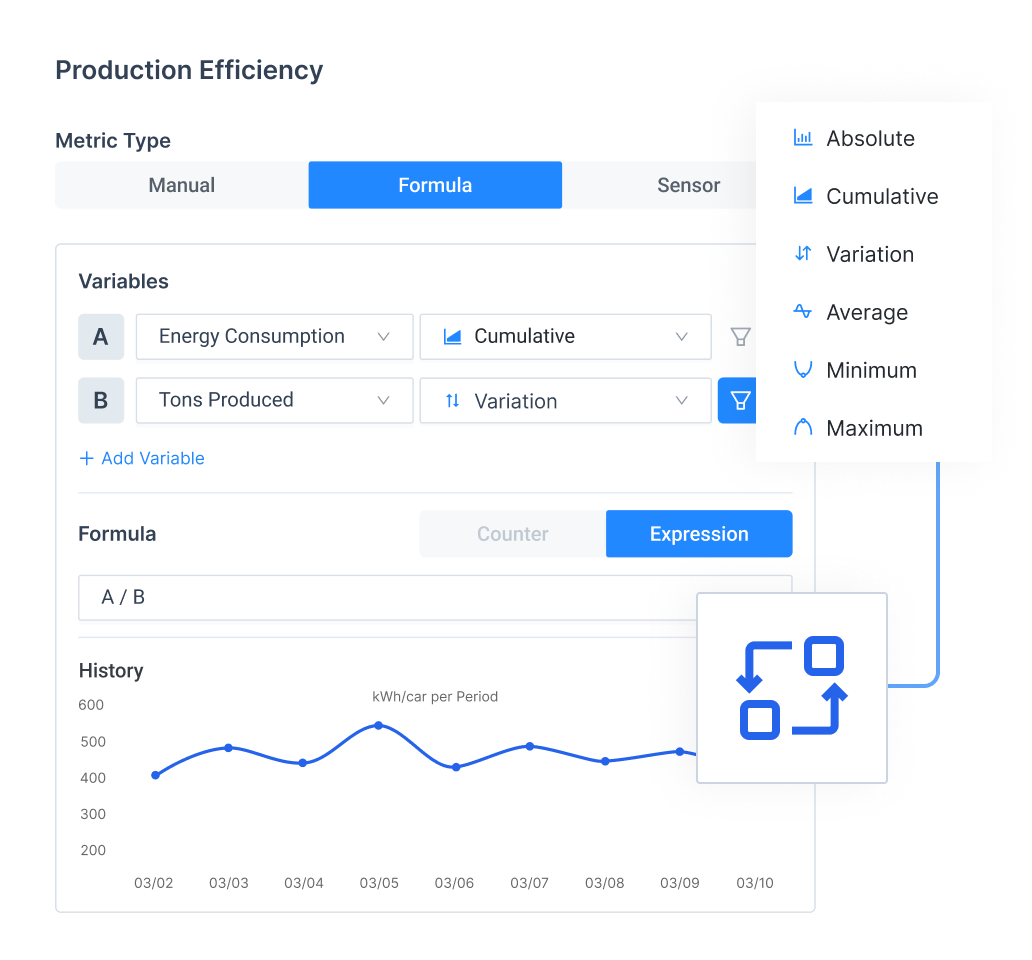

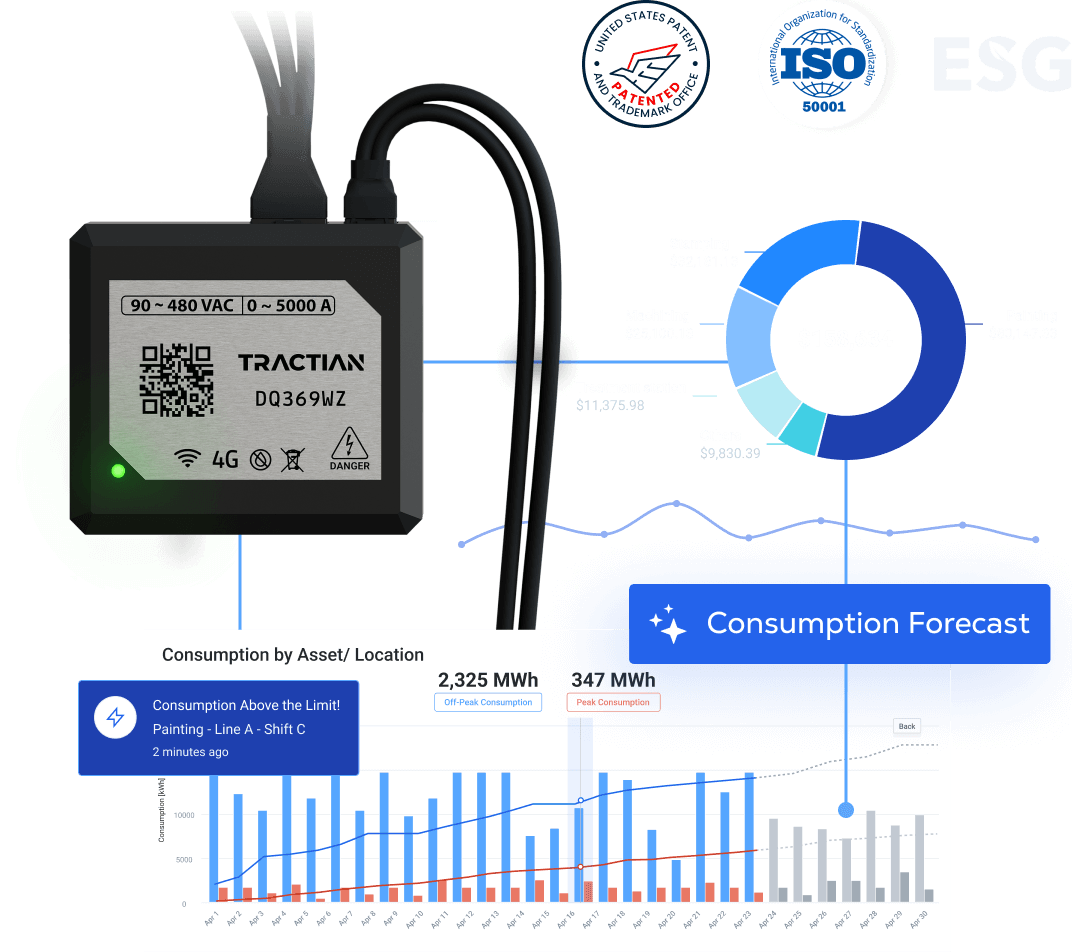

Energy Trac is a powerful energy management system purpose-built for industrial facilities. It provides real-time, granular monitoring of energy consumption and demand across assets and processes.

With intelligent insights and customizable KPIs, Energy Trac empowers data-driven optimization to reduce waste, cut costs and improve overall efficiency.

Key features include:

Non-invasive, plug-and-play sensors for easy deployment

Consumption and cost tracking for individual assets and sectors

Customizable dashboards and automated reporting

AI-powered anomaly detection and alarms

Condition-based monitoring to ensure power quality

Integration with utility meters and submeters

Why should you choose Energy Trac?

Energy efficiency powered by data intelligence.

reduction in consumption KPIs per product

reduction in demand costs

reduction in excess energy costs

Energy Trac is the industry-leading solution to enable and sustain best-in-class energy efficiency for industrial companies. Embrace the power of energy efficiency with Energy Trac.

Other Articles About Energy Efficiency

7 Strategies for Enhancing Energy Efficiency in the Industrial Sector

Do you understand the true power of energy efficiency? - Not just saving a few bucks on the next electric bill, but...

Artificial Intelligence Assisted Maintenance

Much is discussed about different types of maintenance and how they’ve evolved over time. But one thing is...

Artificial Intelligence in Maintenance: 6 Strategies

Picture this: you’re staring at a production line humming rhythmically, each machine in perfect sync. Seamless...