The evolution of industrial processes over the last decades and the advent of Industry 4.0 have placed maintenance as one of the protagonists of industrial processes.

Predicting failures and possible downtime in production processes has become essential to ensure availability and reliability of assets, as well as for the productivity of the industry as a whole.

In this scenario where automation gains more and more space, the future of industries has a name and is called prescriptive maintenance.

But what is prescriptive maintenance and how does it work? In this article, we have gathered all the details you need to know about this trend in asset management. Enjoy your reading!

The evolution of maintenance techniques

In order to understand prescriptive maintenance, it is worth remembering the journey of maintenance systems over time. Since the first Industrial Revolution, the evolution of asset management tools has been dictated by technology.

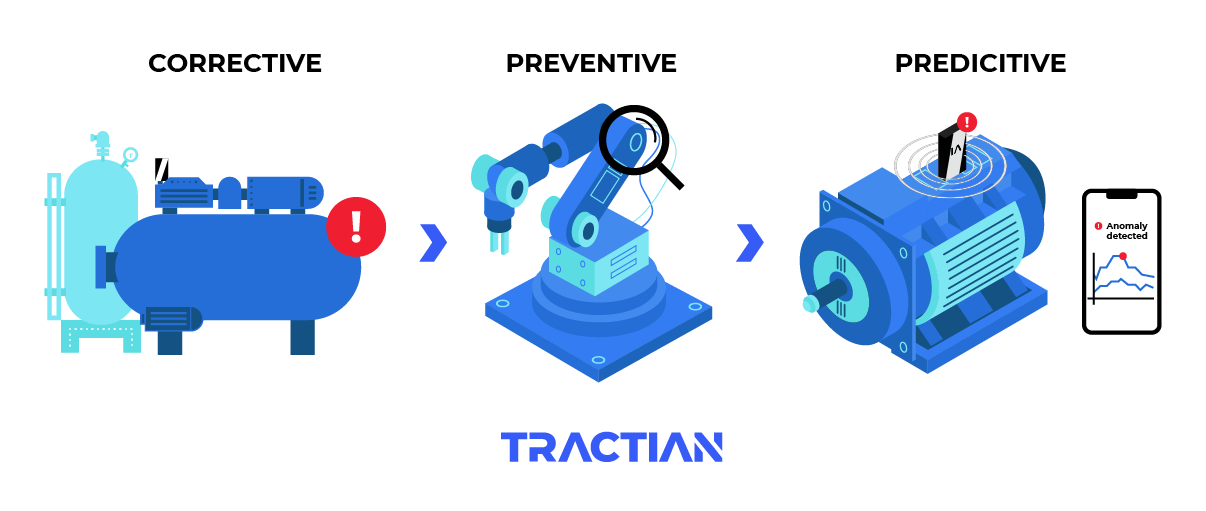

At first, we had corrective maintenance, where there is no prior analysis of the asset’s health and maintenance is only done after failure.

That’s why the corrective maintenance technique is in most cases the one that generates the greatest financial impacts, since failures mean more delays in production and expenses with unplanned repair activities.

Then, industries started to adopt preventive maintenance. Aimed at preventing failures, it involves interrupting the system from time to time to carry out planned maintenance activities, such as machine and equipment overhauls, routine lubrication, inspections, parts replacement due to expiration, etc.

Among the advantages of this type of maintenance are the optimization of resources, accident prevention, and better operation performance.

Predictive maintenance, in turn, brings condition monitoring as a key piece for decision making in maintenance actions within the industry.

The goal is to perform constant failure analysis and thus reduce the chance of wear and damage to equipment.

Online asset monitoring represents a leap forward in predictive maintenance, as it allows real-time data collection and analysis of an asset’s health. This leads to a lower probability of failure, which in turn ensures cost reduction with unexpected downtime, better planning of maintenance routines, especially the preventive maintenance activities, and, as a result, increased productivity of the industrial plant.

Prescriptive maintenance

Prescriptive maintenance can be classified as the evolution of predictive maintenance.

In online monitoring, data collection and analysis is done in real time. This indicates the advantage of resource optimization, since it makes it no longer necessary to have a technician on site to evaluate certain equipment.

The use of IoT sensors, combined with a platform that receives, classifies, and analyzes this data through artificial intelligence and machine learning, culminates in an integrated and assertive system that can determine decision-making, not only indicating the possible problems that an asset may present, but also indicating the most appropriate type of maintenance to be done to avoid that failure.

In other words, predictive failure analysis becomes a prescriptive analysis, in which failure modes are diagnosed before they even occur. In this way, all monitored assets are assessed in real time and automatically, without having to hire an outsourced company or qualify professionals to perform randomly defined predictive activities at widely spaced periods.

The future of the industry is now

As you may have already understood, prescriptive maintenance can be understood as the apex of the evolutionary journey of asset maintenance techniques.

Industries that adopt this type of diagnostic analysis, combining predictive and prescriptive maintenance, can optimize resources and time in their daily routine.

It is as if the maintenance routine were a kind of medical triage. The disease (in this case, the potential failure of an asset) is determined according to its level of criticality. From there, the need or not for “consultation” is evaluated, that is, the need to send a specialist to the site to inspect the asset closely.

This type of technology is already a reality. TRACTIAN’s predictive system, which unites IoT sensors with the TracOS™ maintenance management software, brings all the features that combine predictive and prescriptive maintenance, as well as online monitoring and automated management of the failures tree.

With it, it is possible to obtain the analysis of an asset’s health data, check metrics, generate reports and work orders, automate preventives and organize the whole process of industrial maintenance routines.

Thus, the process becomes smarter and simpler, ensuring that assets perform better and extend their life cycle, improving the maintenance plan as a whole.

Prescriptive maintenance is establishing itself as one of the most efficient new digital technologies, bringing more positive results to the industry.

When we think about this fully integrated system, with data in the cloud, automated decision making, sensors that make the workflow faster, and test and measurement equipment working more easily, it is possible to glimpse the future of the industrial sector – which, by the way, has already started, after all, Industry 4.0 is already a reality.

Ready to face the future of maintenance? Talk to one of our specialists and bring this new reality to your industry.