Challenge

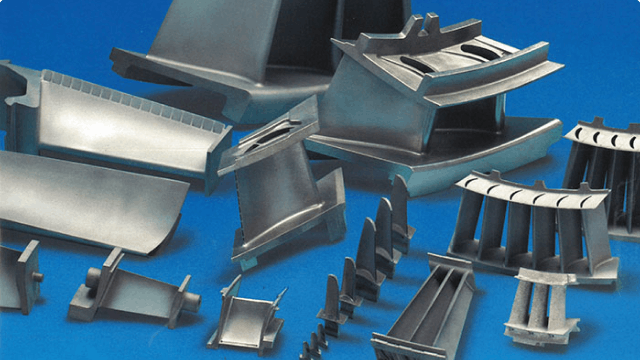

SWARCO operates a 24/7 facility with one of the most advanced direct melters in the U.S., producing high-specification glass beads used for road safety.

The problem? This unique melter depends on hard-to-source overseas parts. If a critical component fails, it can take up to 6 months to replace.

Downtime isn’t just inconvenient—it’s expensive and can bring production to a standstill.

Key issues SWARCO faced:

- No predictive maintenance in place

- Every asset was critical—failure meant halted production

- Long lead times for replacement parts

- Manual inspections couldn’t keep up with operational risk

If a critical asset fails: $28,000/day in lost production.

Solution

To avoid failures and gain better control over equipment health, SWARCO implemented Tractian Condition Monitoring across 45+ critical assets. These wireless sensors track vibration and temperature in real time, feeding AI-powered diagnostics back to the team.

With Tractian, the team now:

- Receives early warnings about equipment issues

- Pinpoints root causes of failure with automatic diagnostics

- Acts quickly with step-by-step guidance on what to inspect and fix

- Runs condition-based maintenance backed by real data—not guesswork

Impact

Since deployment, SWARCO has been able to prevent multiple potential failures—including a critical unbalance issue on one of its furnaces.

With actionable alerts and faster troubleshooting, SWARCO has shifted from reacting to problems to preventing them altogether.

- 40+ faults detected and diagnosed

- Furnace failure avoided via early vibration alerts

- $420,000 saved, driven by avoided breakdowns and reduced inspection time

- Over 350,000 data samples analyzed to build deeper asset intelligence

What's Next

As their new plant ramps up production, SWARCO is using Tractian to build a more resilient maintenance program from day one.

With fewer surprises and better visibility into asset health, the team is equipped to keep operations running—without delays or downtime.