Challenge

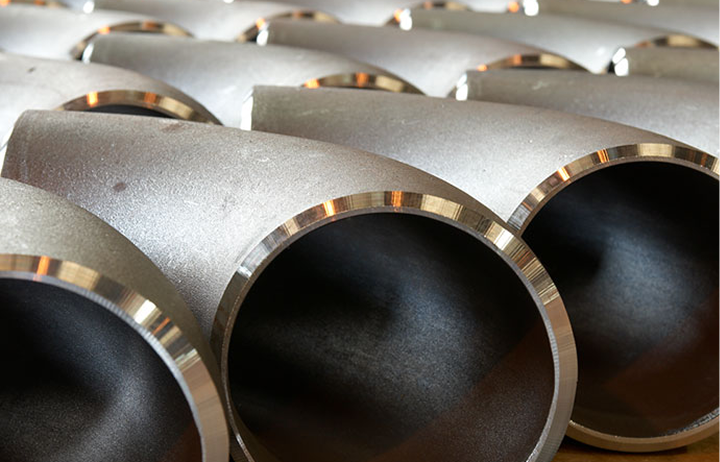

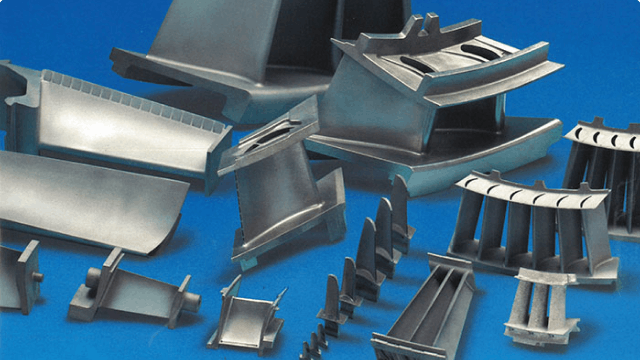

PCC Fasteners is a global leader in the manufacturing of aerospace-grade fasteners, supplying precision components to industry giants like Airbus and Boeing. The company operates over 120 manufacturing sites worldwide, employing approximately 20,000 people.

In 2023, they began preparing a new plant in West Chester, Ohio, with a unique goal: build a complete maintenance structure before a single production line went live.

For Abel G., Maintenance Manager at PCC and a longtime advocate of smart maintenance systems, it was the perfect opportunity to do things differently.

When Abel arrived at PCC, the team had already adopted Fluke’s eMaint CMMS. But it wasn’t meeting expectations.

They needed a mobile-first platform built for technicians, not IT teams. Something intuitive, easy to use from day one, and comprehensive enough to support all their maintenance routines without extra tools or workarounds.

Solution

Abel had worked with Tractian’s condition monitoring sensors before. When he relocated to Ohio, he reached out directly to bring Tractian’s CMMS to PCC. With no legacy processes holding the team back, they implemented the platform from the ground up.

The platform became the single source of truth for maintenance planning, execution, and documentation, without needing to rely on spreadsheets or external tools.

Implementation priorities:

- Creating preventive routines before production began

- Structuring AI-generated SOPs tailored to their equipment

- Defining permissions and safety workflows in line with aerospace compliance

- Building execution flows using just one system-no need for secondary platforms

- Centralizing work orders, tasks, and traceability in an interface anyone could use

Impact

Before the plant was even fully operational, the team saw tangible benefits in how maintenance processes were organized and executed.

Abel’s team ran internal audits smoothly, aligned with aerospace quality requirements, and received positive feedback from evaluators, well before the first unit rolled off the line.

Today, the CMMS contains the foundation of PCC’s proactive maintenance strategy. As production ramps up, the team is already planning the next phase: KPIs, failure tracking, and long-term optimization.

What's Next

With operations launching soon, PCC Fasteners is well-positioned to lead with a proactive, intelligent approach to maintenance. The foundation is already laid-they’ve built a connected, auditable, and technician-friendly system designed to meet the highest industry standards.

As Abel puts it: