Yara reports that a partial interruption in fertilizer production could potentially affect up to

80%

of the human food supply chain.

Yara

TRACTIAN’s GUIDE TO RELIABILITY IN THE CHEMICAL INDUSTRY

Find out how the world's leading fertilizer industry transformed its maintenance sector into one of the most efficient and profitable, boosting production reliability with IoT sensors and AI-powered software.

TRACTIAN customer outcomes in the Chemical Industry:

700%

Average Return on Investment (ROI)

45%

Increase in Reliability

30%

Cost Savings on Preventive Maintenance

TRACTIAN’s GUIDE TO RELIABILITY IN THE CHEMICAL INDUSTRY

How Yara International's Maintenance Set the Standard for Efficiency and Profitability

Find out how the world's leading fertilizer industry transformed its maintenance sector into one of the most efficient and profitable, boosting production reliability with IoT sensors and AI-powered software.

TRACTIAN customer outcomes in the Chemical Industry:

700%

Average Return on Investment (ROI)

45%

Increase in Reliability

30%

Cost Savings on Preventive Maintenance

Company

Yara International

Plants

21

Employees

< 4.200

Assets Monitored by Smart Trac

600+

Generated Insights

1.300+

Identified Failures

141

Project Timeframe

15 months

3-month ROI

700%

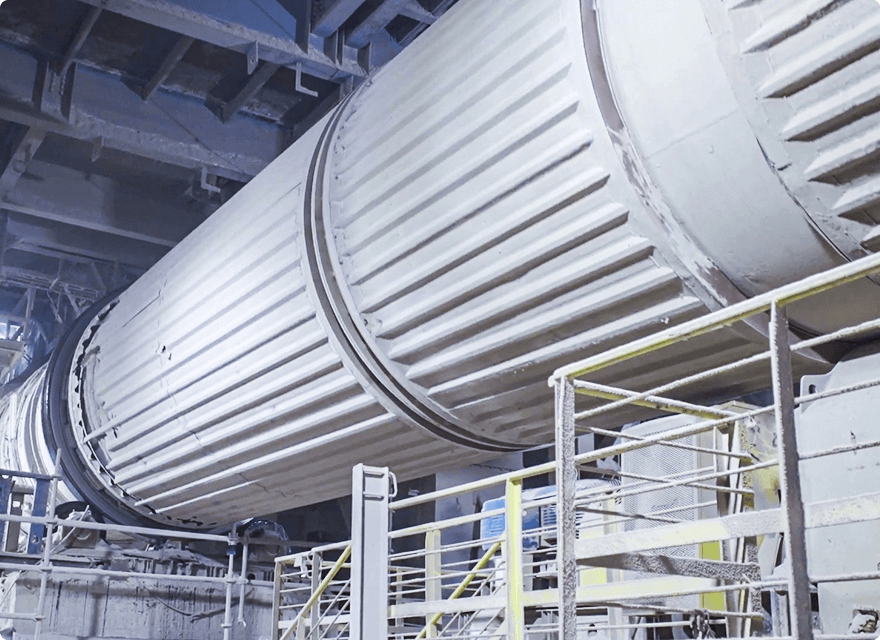

The Norwegian multinational, widely recognized as the leading producer of nitrogen-based mineral fertilizers, is a client of TRACTIAN’s AI-driven online vibration and temperature monitoring system.

Through the sensors, the company averted potential disruptions that could have halted the entire production process, affecting up to 80% of the human food supply chain.

> Find out more about our technology

Yara reports that a partial interruption in fertilizer production could potentially affect up to

80%

of the human food supply chain.

PART 1 - THE CHALLENGE

For months, Yara sought a solution that could handle the company's tough corrosive conditions and also preemptively detect failures. This would empower the team to take action before any breakdown occurred.

Even a single day of machine downtime was unacceptable, so identifying possible failures was a significant concern for the company. Yara's reports suggest that a partial interruption in fertilizer production could potentially impact up to 80% of the human food supply chain.

A robust hardware solution was essential. It needed to be highly protected to endure the corrosive environment without operational hiccups. At the same time, it had to eliminate the need for technicians to manually inspect machines. Furthermore, the information had to be accurate, consistent, effortlessly accessible, and easily recordable, ensuring remote production control.

Even with our robust inspection plans, there are intervals in between when we can't get a complete view of everything happening inside the machines. TRACTIAN’s system essentially acts as if our eyes were placed all over the factory, using top-notch hardware and software.

Gustavo Nazar

Maintenance Analyst

Yara International

Yara units reported an ROI of more than

700%

in just 3 months.

Part 2 - THE SOLUTION

With this insight alone, the company saved

over $13,000.

The ease and adaptability of TRACTIAN's solutions are seriously impressive, fitting into any industry type, even those with special quirks. It's no surprise that in a short while, many of Yara’s plants got wind of the PGR results through online monitoring and were keen on rolling out the project across their units.

Ronaldo Blum

Corporate Maintenance Specialist

Yara International

Part 3 - 3 YEARS IN 3 mONTHS

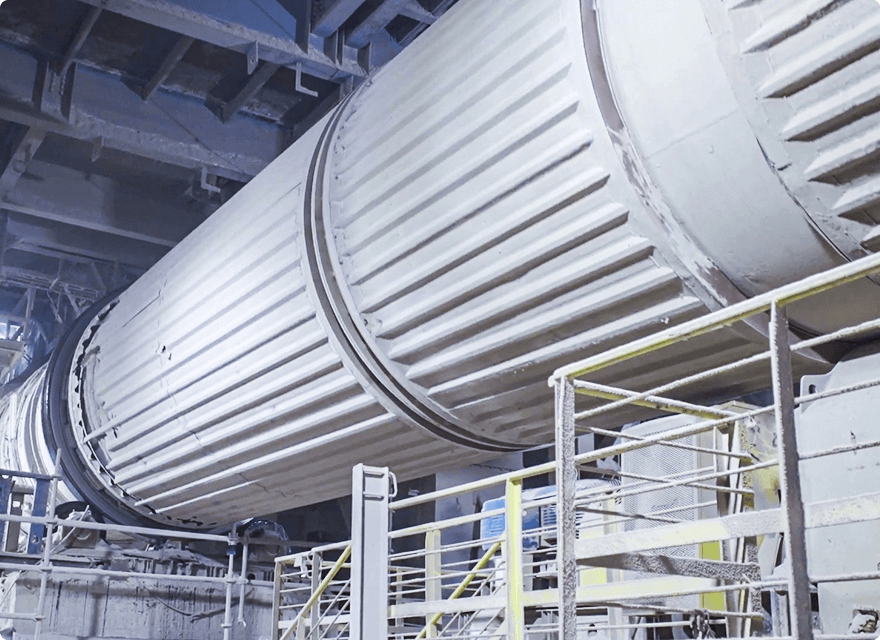

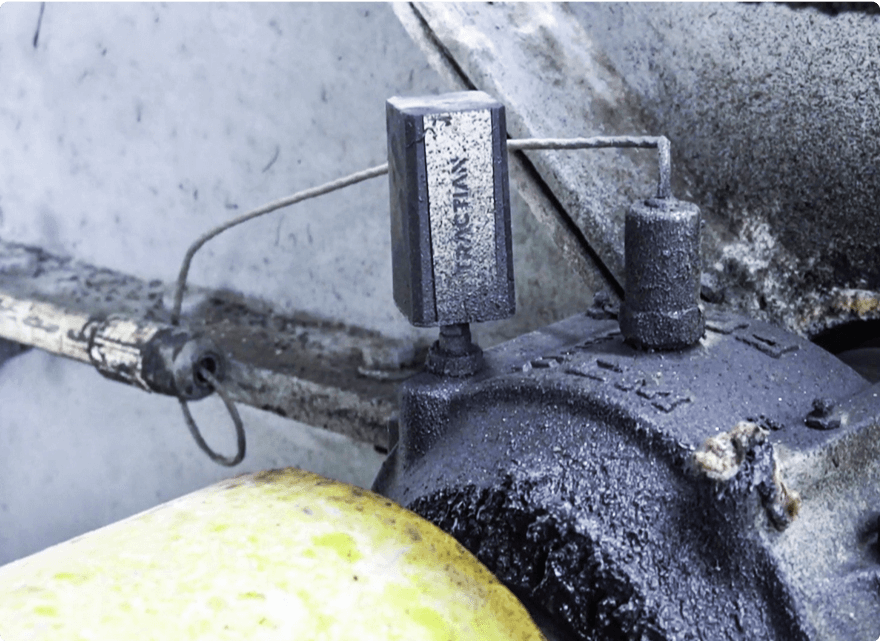

Given the harsh plant environment, the company needed a tougher, more rugged product.

TRACTIAN swapped out metal materials for stainless steel 304 and brought a patented industrial adhesive to replace glue. Paying attention to the nitty-gritty details meant zero replacements for the new sensor version.

Asset

Asset

Mug Lift

Gas Exhaust Fan

Conveyor Belt

Corresponds to

Corresponds to

39,7%

27,7%

12,8%

Sub-assets

Sub-assets

Bearing

Motor

Reducer

Corresponds to

Corresponds to

39,7%

35,5%

24,8%

PGR1-0060-VT06 - Motor

PGR1-0060-VT06 - Bearing

Today, 15 months after TRACTIAN became a part of Yara's everyday operations, there are 21 plants and more than

> 4.270

employees who benefit from TRACTIAN vibration and energy monitoring solutions.

Part 4 - THE EXPANSION

What started in a single facility by 2021’s end has now expanded to cover more than 20.

This success is all thanks to the prevention of critical breakdowns in the pilot phase, which monitored under 10 assets and still achieved an impressive 700% ROI within just 3 months.

This expansion wasn't a gradual thing; time wasn't to be wasted. The ten-initial monitored assets grew to over 600. Over 4 million data samples have been gathered without technicians having to get close to the machines. Every sample has been meticulously examined and transformed into precise recommendations by TRACTIAN's patented Artificial Intelligence.

Yara considers maintenance a cornerstone of its strategy, aiming to deliver top-notch products to end-users and keep the global food chain going. The world's largest fertilizer maker has partnered with the world's most advanced maintenance technology, consistently impressing Yara's teams and leadership with astonishing results.

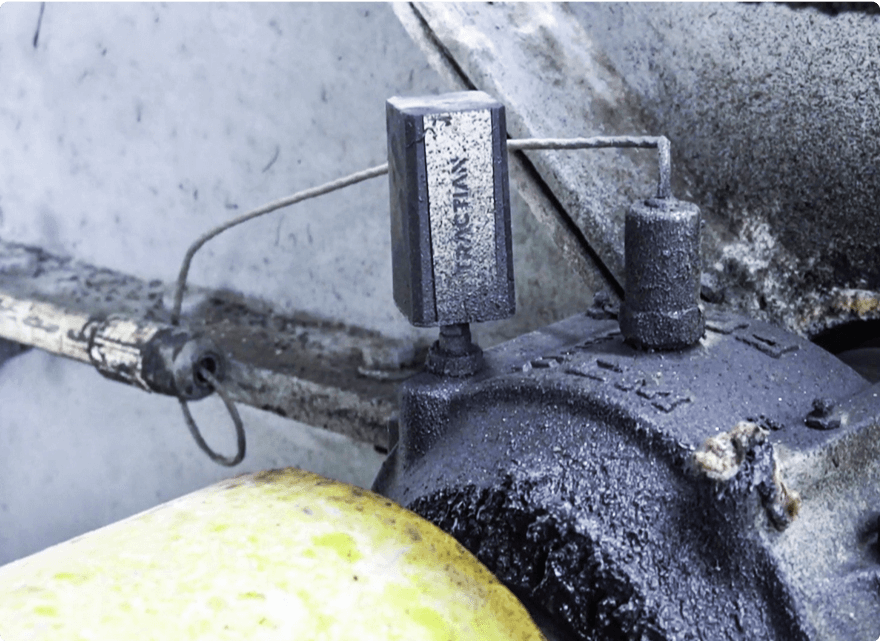

Take a look at the features that Yara International teams use the most on TRACTIAN’s platform to keep tabs on and manage assets.

Analytics

In a single year, over 4 million data collections have been conducted across 600 critical assets. The team performs daily tracking of automated analyses through Analytics, which provides a variety of spectra and graphs to vibration analysts.

Failure Insights

Delivered via notifications or emails, these insights are geared for mobile-first usage and are dispatched daily. They alert the team to abnormal machine behaviors and provide detailed recommendations generated by TRACTIAN's Artificial Intelligence. These pointers guide technicians on how to avert failures. On average, each identified issue has saved Yara around $12,000, adding up to an estimated total saving of $1.6 million in slightly over a year.

Online Floorplans

With Floorplans, an exclusive TRACTIAN feature offering an interactive map of the plant, Yara's maintenance managers can effortlessly monitor all assets and locations at once. The map is updated in real-time and showcases ongoing activities in the facility, making visual management a breeze.

Schedule a demo.