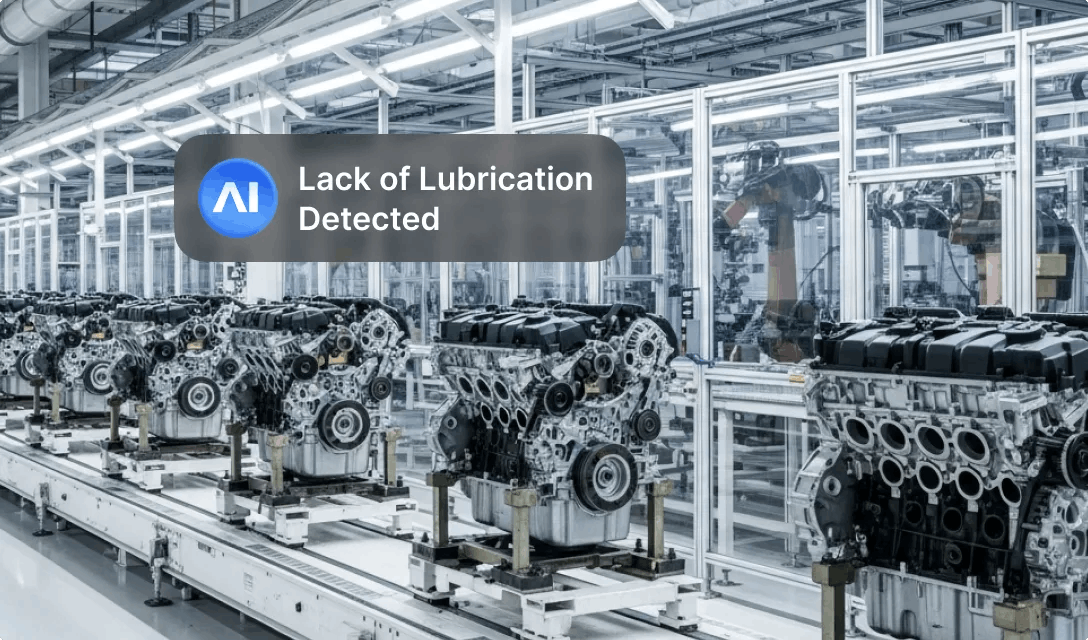

CHEMICAL PLANTS CMMS AND CONDITION MONITORING SENSORS

Reliability That Holds Under Pressure

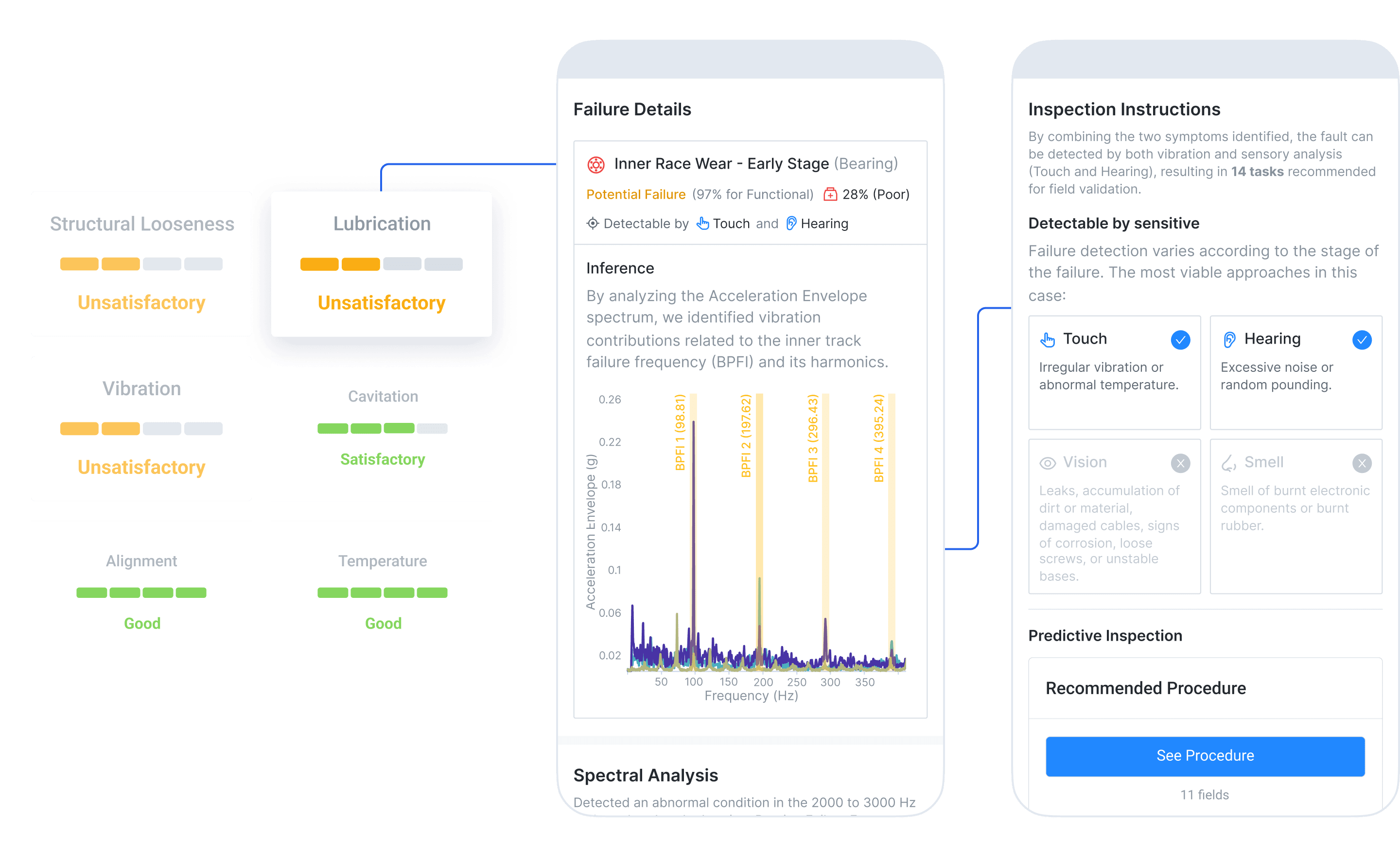

In chemical manufacturing, safety and uptime are non-negotiable. Tractian combines an AI-powered CMMS with real-time condition monitoring to help teams prevent failures, ensure compliance, and extend asset life in even the harshest environments.