CMMS SOFTWARE FOR FOOD & BEVERAGE

Powering Uptime and Compliance in Food & Beverage Plants

Track work, monitor assets, and keep production running smoothly - all while ensuring your facility meets quality standards and never fails an audit.

Powering Uptime and Compliance in Food & Beverage Plants

Track work, monitor assets, and keep production running smoothly - all while ensuring your facility meets quality standards and never fails an audit.

These companies replaced downtime with oversight, and turned maintenance into a competitive edge.

Decrease in Unplanned Downtime

Increase in Scheduling Compliance

“With everything centralized in one platform, within Tractian CMMS, we finally had the visibility to act fast, plan smarter, and show real results.”

Paul Morais

Director of Maintenance

in Production Savings

Avoided Downtime

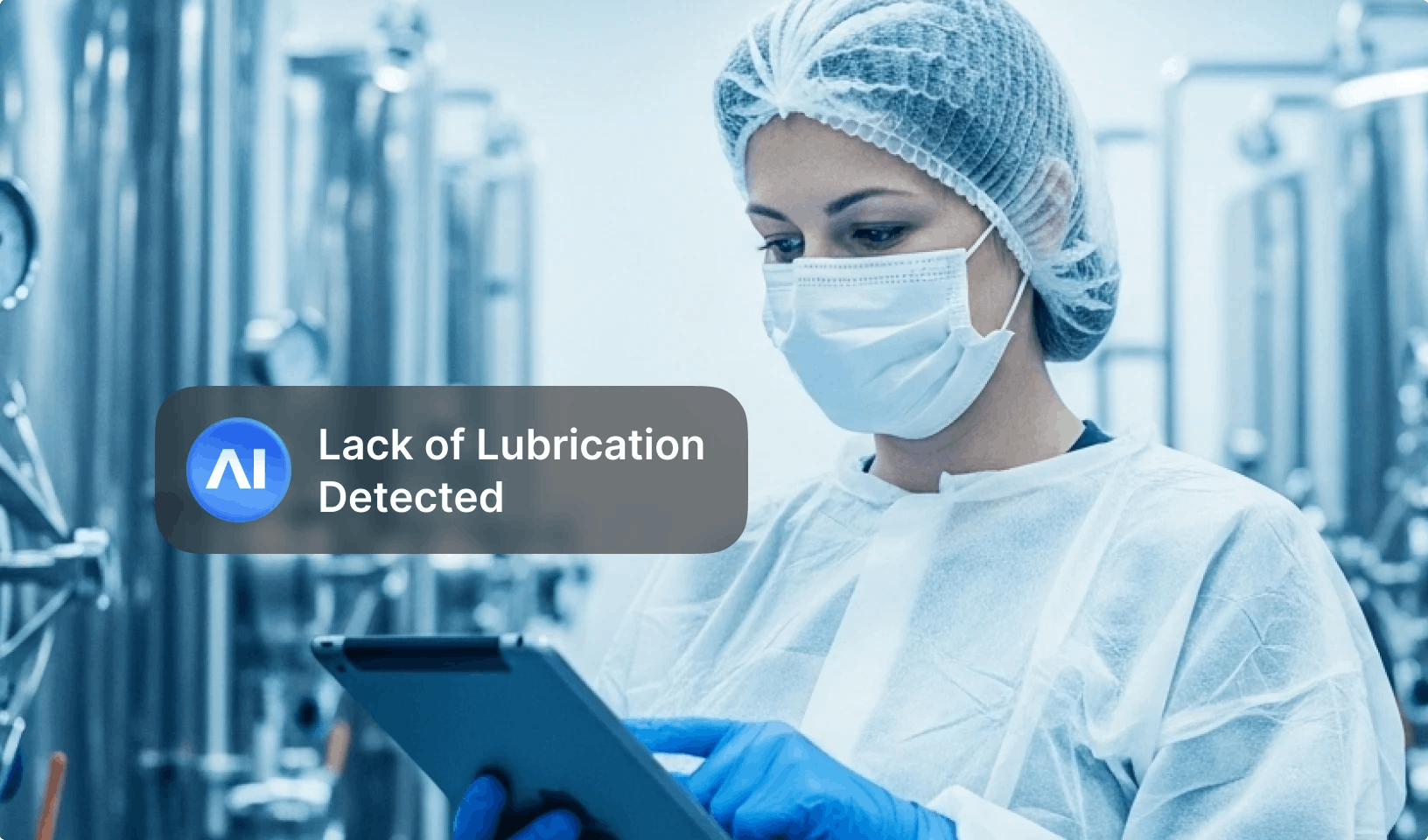

“There were some issues that I would say, if not for having Tractian, we would have never noticed… A lubrication problem, for example, we could go out and lubricate it and recheck it on Tractian platform and see that it fixed the problem.”

Jacob Hoffine

Reliability Engineer

HOW TRACTIAN HELPS FOOD & BEVERAGE MANUFACTURERS

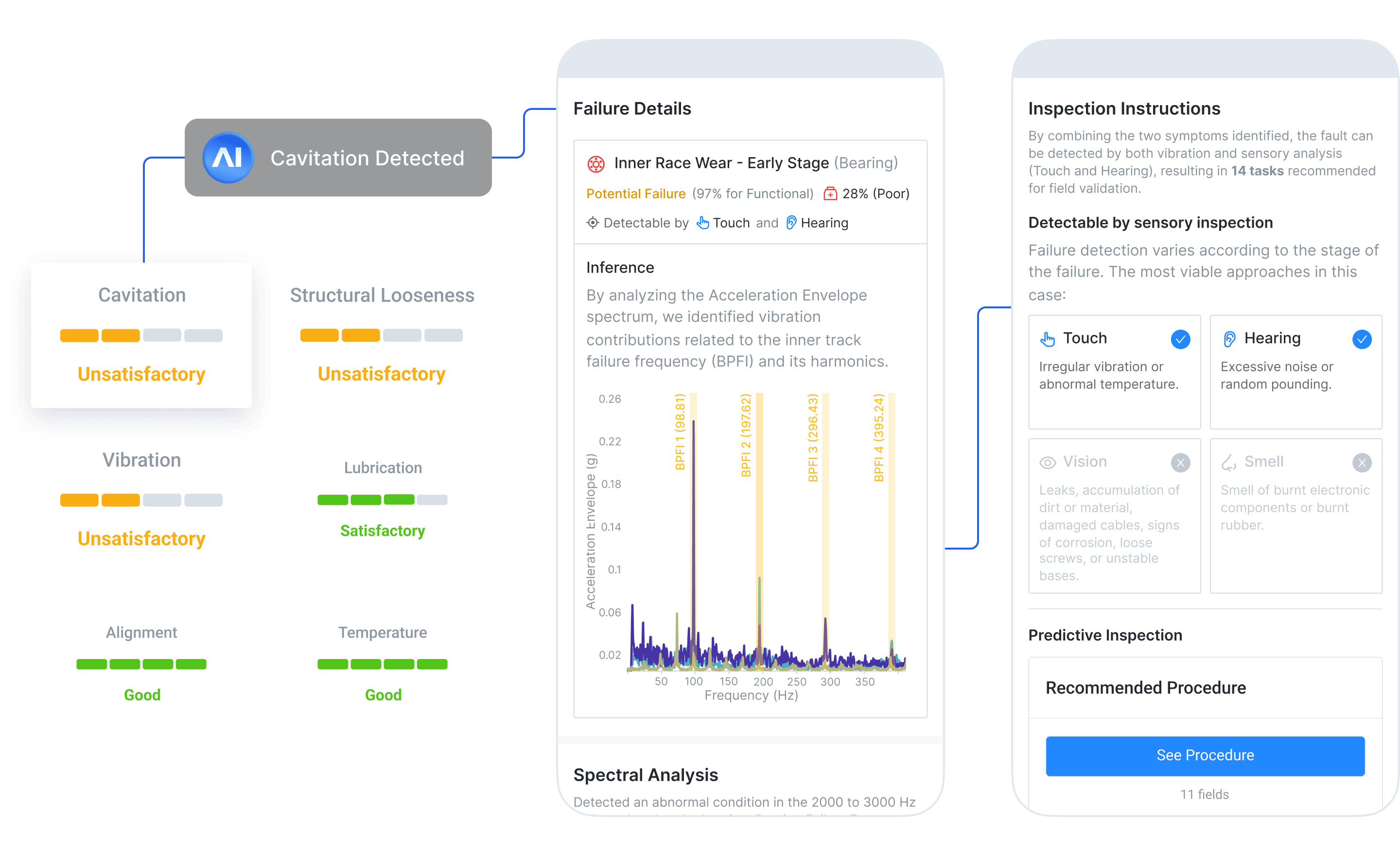

In F&B, undetected failures can ruin batches, break safety limits, and delay fulfillment. Tractian gives your team real-time visibility into asset health, so you can act before production or quality takes a hit.

DON'T TAKE OUR WORD FOR IT

I like that I can track all of our assets from one location. If a motor is having issues in one part of the plant, and another on the other side of the plant, I am able to basically troubleshoot both motors from the same place.

Nicholas D.

Maintenance Lead Supervisor

Koch Foods

Tractian's AI eliminates the need for time-consuming program setup and analysis. With the right technical information, I was able to get valuable insights within a few weeks. Tractian is agile with platform and AI updates based on the feedback provided from the end user.

Jacob Hoffine

Reliability Engineer

Ingredion

Tractian has been very useful with keeping track of technicians. It also helps a lot with inventory usage. The fact that it's easy to navigate through the app. They also have a great team that is always giving us the attention we need. Since we have many assets, implementation has taken some time but it has been worth the documentation of everything.

Anthony A.

Plant Engineer

The Fillo Factory

I like the ease of tracking equipment without having to constantly observe. Tractian does the work for you.

Jordan D.

Maintenance Supervisor

Koch Foods

I like that it is a very intuitive and easy-to-understand tool for the user. Similarly, the accuracy of the platform is very good compared to others in the same field. The support from experts in the area who can give us approval or guide us through the alerts adds value.

Verified User in

Food Production

A single pane of glass to manage maintenance, monitor machines, and optimize production processes.

Condition Monitoring: predict failures, avoid downtime, and cut operational costs.

Monitor machines

Maintenance Management & Reliability: log every task and manage real-time data.

Manage assets

Smarter Operations & Data Intelligence: transform process data into profits.

Optimize processes

How CMMS Supports Food Safety and Compliance

Learn how a CMMS can help food manufacturers meet their safety standards, reduce risks, ensure traceability, and streamline compliance efforts.

Read More

How To Prevent Cross-Contamination In The Food Industry?

Prevent cross-contamination in food plants with structured maintenance, regulatory alignment, and real-time execution.

Read More

CIP Cleaning: How to Ensure Food Safety Standards

Learn how CIP cleaning impacts food safety, key challenges, and how a CMMS can help optimize cleaning cycles for compliance and efficiency.

Read More

FAQ