Industry is the backbone of our economy: it moves millions of dollars and generates many formal jobs every year.

It is part of many aspects of our daily lives – what we eat, wear, drive and the tools that help us. Everything comes from industry companies.

Over time, the industry has progressed. The 4th Revolution, Internet of Things, digitalization of information and activities, and Artificial Intelligence: these are all part of the sector. That is why today, in order to adapt to this pace, factories cannot stop.

And the ones who make this possible are the maintenance workers. The professionals are the fundamental piece, they are the ones who sustain the rhythm and, besides operating the machines, they need to be in constant contact with them to keep them running.

They are also the ones that are often unattended, since maintenance is still seen as a source of excessive expenses and delays in production.

With the help of state-of-the-art technology that facilitates and optimizes maintenance routines, workers on the factory floors achieve greater reliability and availability of machines – and, consequently, better results and profitability for the companies.

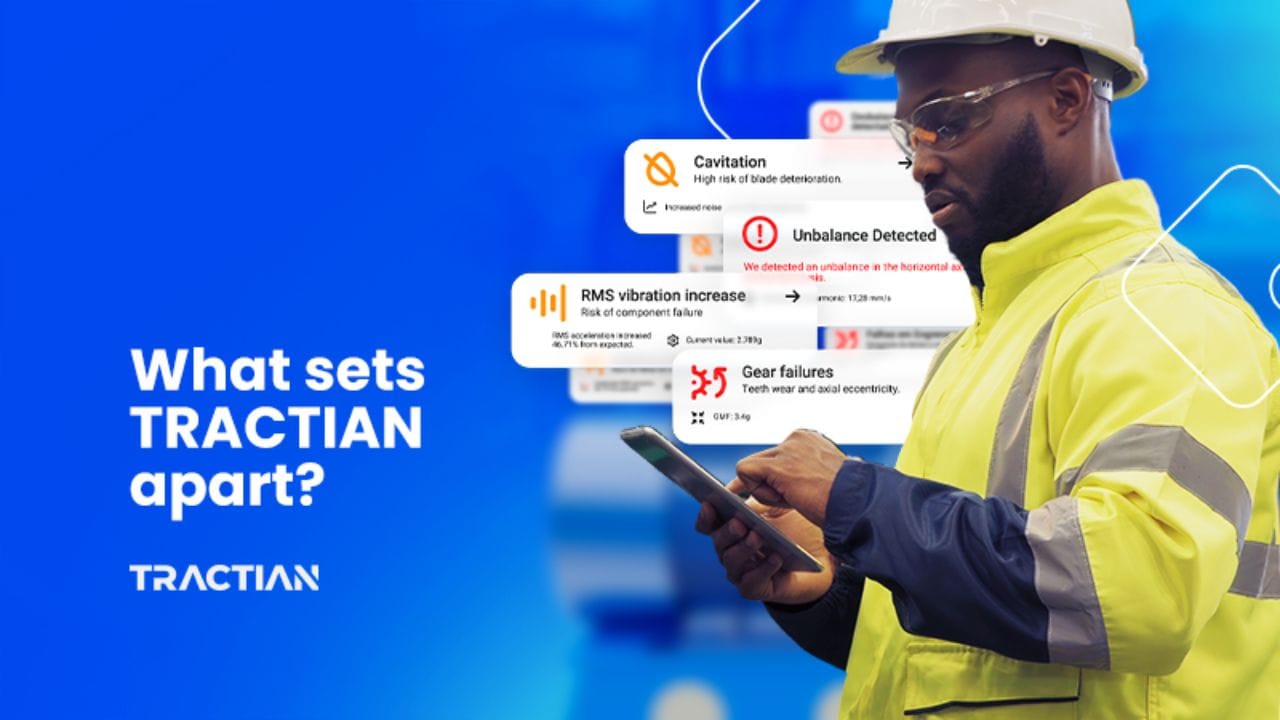

This is TRACTIAN’s goal. Revolutionize maintenance through predictive solutions that anticipate machine breakdowns and optimize management, so that the routines of professionals are easier and more efficient.

What Is TRACTIAN and How Does it Help Your Maintenance Management?

With that in mind, we brought you this article that features the top five reasons why maintenance managers love TRACTIAN. Enjoy!

1. Real-time Remote Online Asset Monitoring

Collecting asset data to identify anomalies can be done in two ways. The first is offline, using manual sensors and collectors that rely on the physical presence of industry professionals.

Learn more about the difference between offline and online monitoring

Collections are infrequent and are established according to pre-programmed intervals on non-periodic inspection routes. This means that, between one analysis and another, equipment failures can arise and there is a higher probability of machine breakdown and production downtime.

In online monitoring, data is collected by IoT (Internet of Things) sensors in real time and automatically, without requiring employees to go to the machines.

This is the method TRACTIAN works with. Smart Trac sensors collect temperature, vibration, and hour meter data from the assets and transmit the information immediately to the online monitoring platform.

Which assets does the TRACTIAN sensor monitor?

Since collection happens automatically and remotely, workers on the factory floor do not have to risk being in hostile environments and hard-to-reach places – online monitoring brings more security, as well as convenience, to the professional.

Also part of TRACTIAN’s predictive system are the Energy Trac sensors, which collect data on energy consumption, current, voltage, and power.

The sensor is allied to the same platform as Smart Trac, and there the team can view the most important indicators of the electrical network, information about quality and energy efficiency of the plant, and receive alerts before electrical and mechanical failures.

Energy Trac also performs a complete diagnosis of the grid’s health, tracks the operating window in real time, and performs an automatic calculation of consumption vs. demand.

Remember: both sensors are very quick to install – 3 minutes for the Smart Trac and a maximum of 10 minutes for the Energy Trac -, require no training and are not at all invasive.

What Is TRACTIAN and How Does it Help Your Maintenance Management?

2. No need for industrial Wi-Fi

Traditional sensors and offline monitoring require requests to the I.T. team for installation support, which takes time, bureaucratic processes, and effort.

We know that data security is an important factor when deciding to adopt a solution. With the world connected and with a hyper-speed of information, a simple change can jeopardize the entire production system.

One of the most interesting features on the TRACTIAN sensors, from a maintenance point of view, is that the equipment has a mobile network receiver and transmits the data to the platform via 3G/4G connection.

The transmission of information is protected from intruders, since the industrial WiFi network is not used and does not use gateways. So the maintenance team is not barred by blocked network ports and will not need to ask for help from the I.T. team. This is one of the main distinguishing features of the system, according to maintenance managers.

The information is also encrypted, from the collection to the users. This means that no one but those involved in the data exchange can access the transmitted content, ensuring the company’s cyber security.

TRACTIAN was named one of the fastest-growing SaaS companies in the world

3. Platform that generates automatic insights

Remember when we talked about the online monitoring platform? It’s an ally to the sensors that collect the data, since it analyzes it, and issues alerts, diagnostics, and prescriptions to the staff.

TRACTIAN is ranked as one of the 3 best maintenance softwares in the world

The system helps maintenance managers and all employees to have constant contact and control of the machinery. Through the platform, they can access technical reports automatically, in order to speed up the processes.

The insights also allow for better planning and assertiveness of the best strategies and interventions, which now happen based on condition, and not on predetermined intervals as in Preventive Maintenance.

4. Automate and centralize Work Orders in a simple and integrated platform

Finally, it is time to introduce TRACTIAN’s maintenance management software, the TracOS™ CMMS. The system was created to replace printers, paper and spreadsheets that still dominate the day to day life of maintenance managers.

The CMMS performs complete asset management. It centralizes and automates work orders, besides enabling the creation and customization of WO’s, assigning responsible people, procedures, and metrics.

In the CMMS, shop floor professionals can attach images to facilitate the process and exchange messages with the team via real-time chat. It’s very practical for the workers, and another reason why those who adopt the technology, recommend it.

Maintenance plans are also automated, and you can also prioritize machines automatically with the help of the Asset Tree feature, which records maintenance histories and important information.

5. Its purpose is to eliminate unexpected breakdowns

The main goal of TRACTIAN’s technology is to optimize and facilitate the maintenance professional’s routine, through failure prediction and more efficient management.

With the solution, access to important insights and information about all machines is in the palm of the worker’s hand, who can thus act predictively.

TRACTIAN named in the Capterra Ranking for emerging favorite CMMS and OEE Software

Some of the main failures detected by the system are: unbalance, misalignment, mechanical play, cavitation, short circuit, overload, overcurrent, anomalous current and voltage peaks, among others.

Data science allied with remote monitoring has become a crucial part of the predictive maintenance model for industries, as it ensures greater control of assets, better anomaly detection, avoiding downtime and generating greater profit for the company.

That is why the TRACTIAN predictive system is the best on the market. If you want to learn more about how to implement it in your plant, contact one of our experts and schedule a demonstration to see our solutions up close!