Predictive Maintenance for the Oil and Gas Industry

Discover how Industry 4.0 technologies transform the oil and gas sector, enhancing safety, operational efficiency, and asset reliability.

Return home

Discover how Industry 4.0 technologies transform the oil and gas sector, enhancing safety, operational efficiency, and asset reliability.

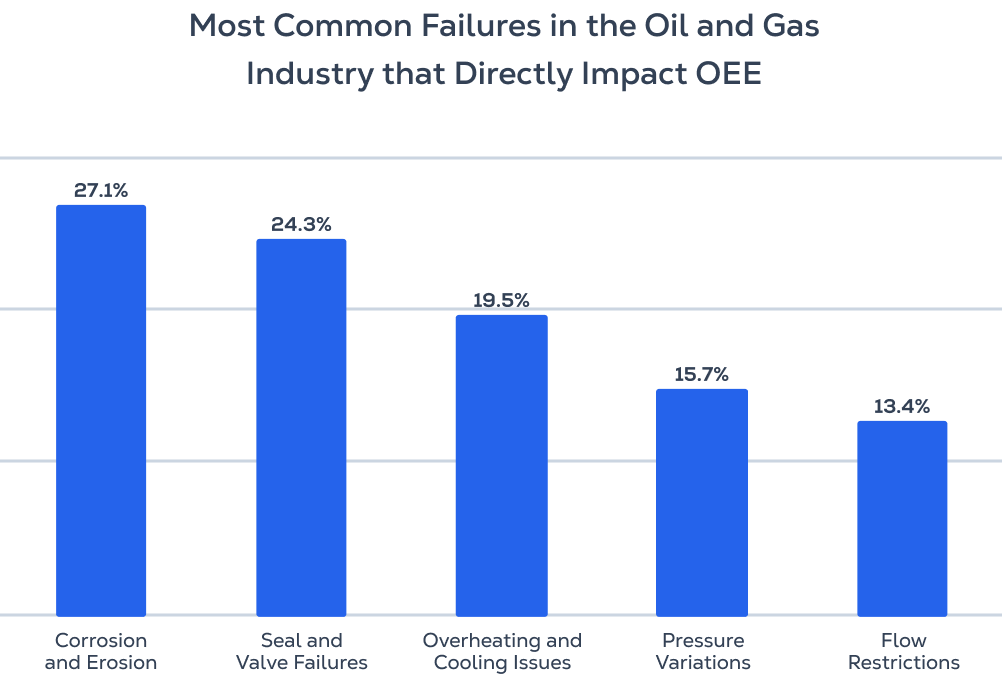

Equipment failures in the oil and gas industry can lead to severe safety hazards, environmental incidents, and substantial financial losses. Predictive maintenance minimizes these risks by ensuring continuous operation and early fault detection, thereby maintaining safety standards, reducing downtime, and optimizing asset performance.

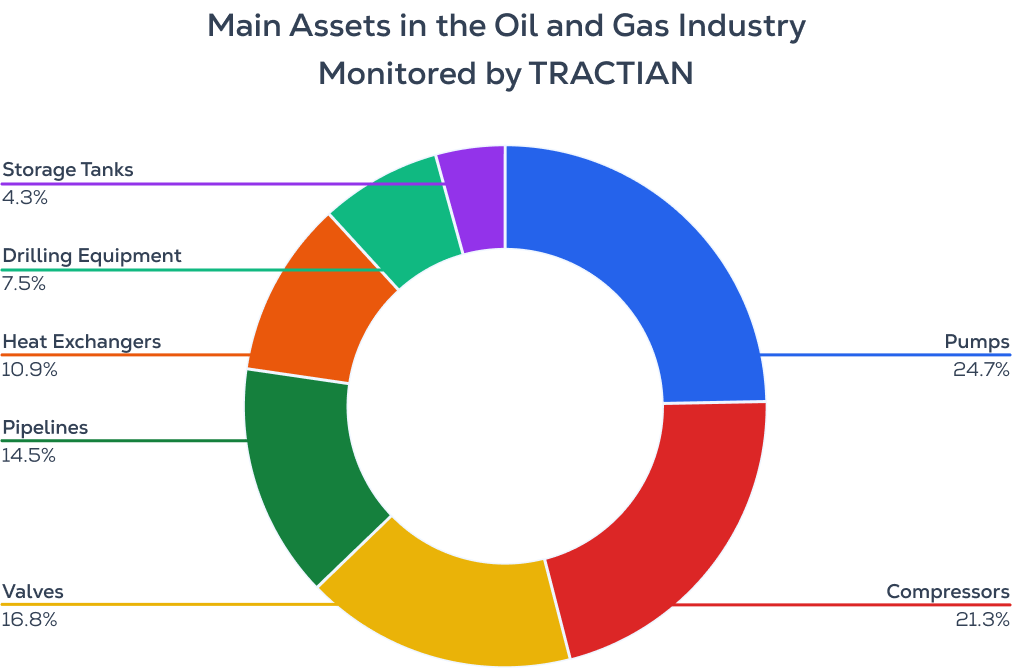

The oil and gas sector involves complex and hazardous processes, requiring robust maintenance strategies to manage a wide range of equipment, from drilling rigs and pipelines to refineries and storage facilities. Continuous improvement and precise maintenance are crucial to maintaining operational efficiency and adhering to safety regulations.

In the oil and gas sector, Overall Equipment Efficiency (OEE) is a vital KPI. Monitoring OEE helps identify inefficiencies and optimize production processes. Key indicators such as availability, performance, and quality metrics are essential to maintaining high safety and production standards.

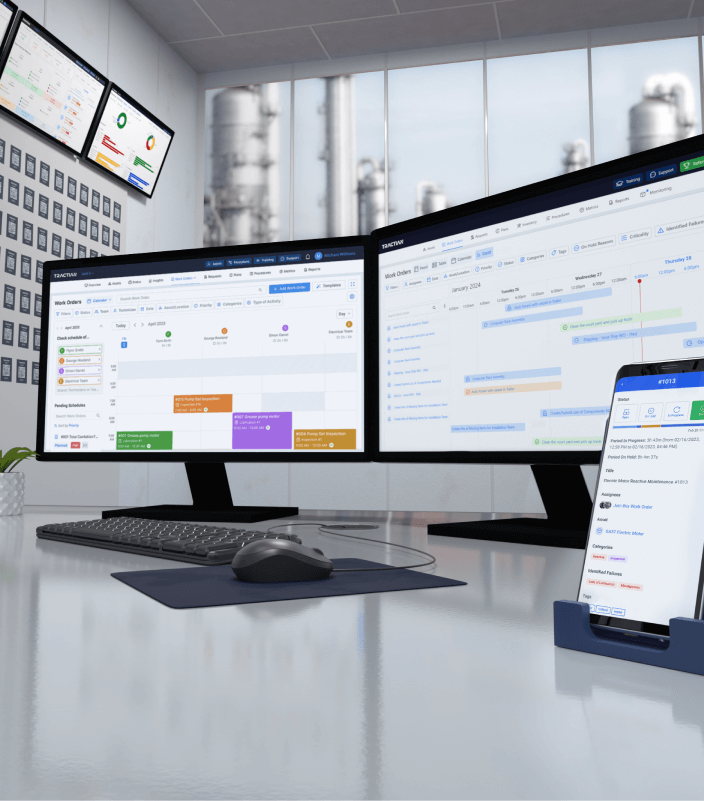

Strategic monitoring of critical points in the production process is essential for early fault detection and performance optimization. Implementing advanced asset management systems and predictive maintenance tools helps reduce unplanned downtime and ensure smooth, safe operations.

From the Internet of Things (IoT) to Machine Learning (ML) and Artificial Intelligence (AI), Industry 4.0 technologies are revolutionizing oil and gas operations. These innovations improve efficiency, ensure safety, and enhance overall operational reliability.

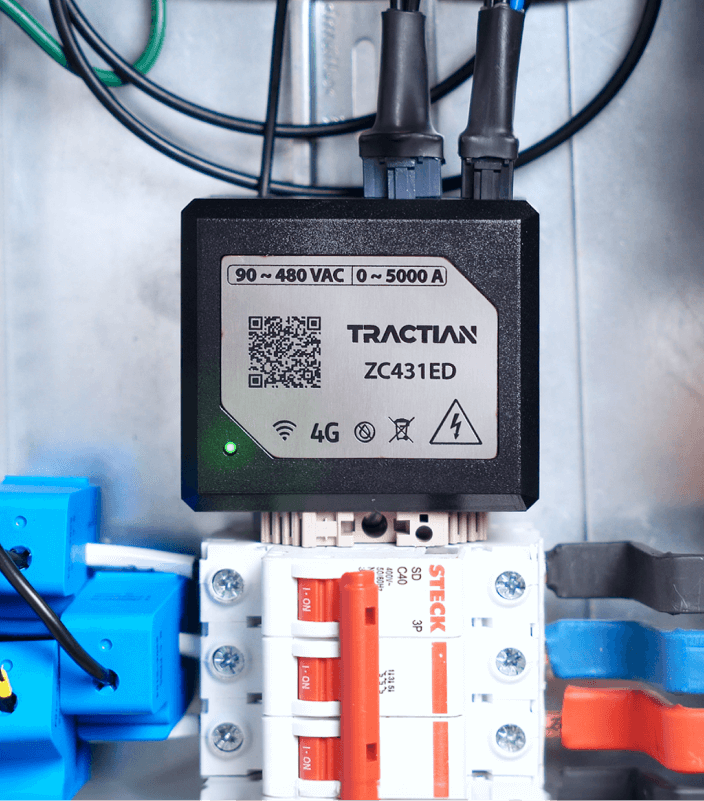

IoT Sensor and Automatic Failure Insights

Asset Management and Plan Automation

Current Measurement and Energy Management

Digitalization and automation lead to more efficient and safer production processes in the oil and gas sector. These advancements enhance product quality, reduce risks, and increase compliance with safety regulations.

Average ROI

1700%

Average payback

30 days

Failures avoided per plant

120 failures

Assets monitored per plant

3500

Regulatory compliance

ISO 45.001 ISO 14.001

Schedule a demo and experience TRACTIAN's 4.0 technology.