- Free Resources

How AI-Powered CMMS Boosts Maintenance Efficiency

Your material is almost ready!

Just complete a quick registration, and your material will be available.

How AI-Powered CMMS Boosts Maintenance Efficiency

Just complete a quick registration, and your material will be available.

You already know spreadsheets can’t scale. This quick read shows the proven features that matter before you spend a dollar.

- Work orders stay live even when devices are offline.

- Built-in SOP templates standardize field execution instantly.

- Asset timeline logs every event automatically.

- Parts inventory links straight to each work order.

- Migrate - Move cleanly from spreadsheets in one afternoon.

- Standardize - Set data rules that drive consistent entries.

- Track - See work in real time—no extra clicks.

- Visualize - Turn raw history into actionable dashboards.

- Sustain - Win executive support with quick-win metrics.

- Digital Maturity Checklist – gauge your current readiness.

A Computerized Maintenance Management System is a single source of truth for assets, work, and parts. It replaces scattered files with structured data so your team can act, audit, and improve faster.

- Work Orders — turn ad-hoc calls into tracked tasks.

- Asset Registry — democratize “tribal knowledge” and end finger-pointing.

- Preventive Schedules — stop calendar creep and surprise downtime.

- Inventory — know what’s in stock before the line stops.

- Reporting — surface performance trends, not raw numbers.

You already know spreadsheets can’t scale. This quick read shows the proven features that matter before you spend a dollar.

- Work orders stay live even when devices are offline.

- Built-in SOP templates standardize field execution instantly.

- Asset timeline logs every event automatically.

- Parts inventory links straight to each work order.

- Migrate - Move cleanly from spreadsheets in one afternoon.

- Standardize - Set data rules that drive consistent entries.

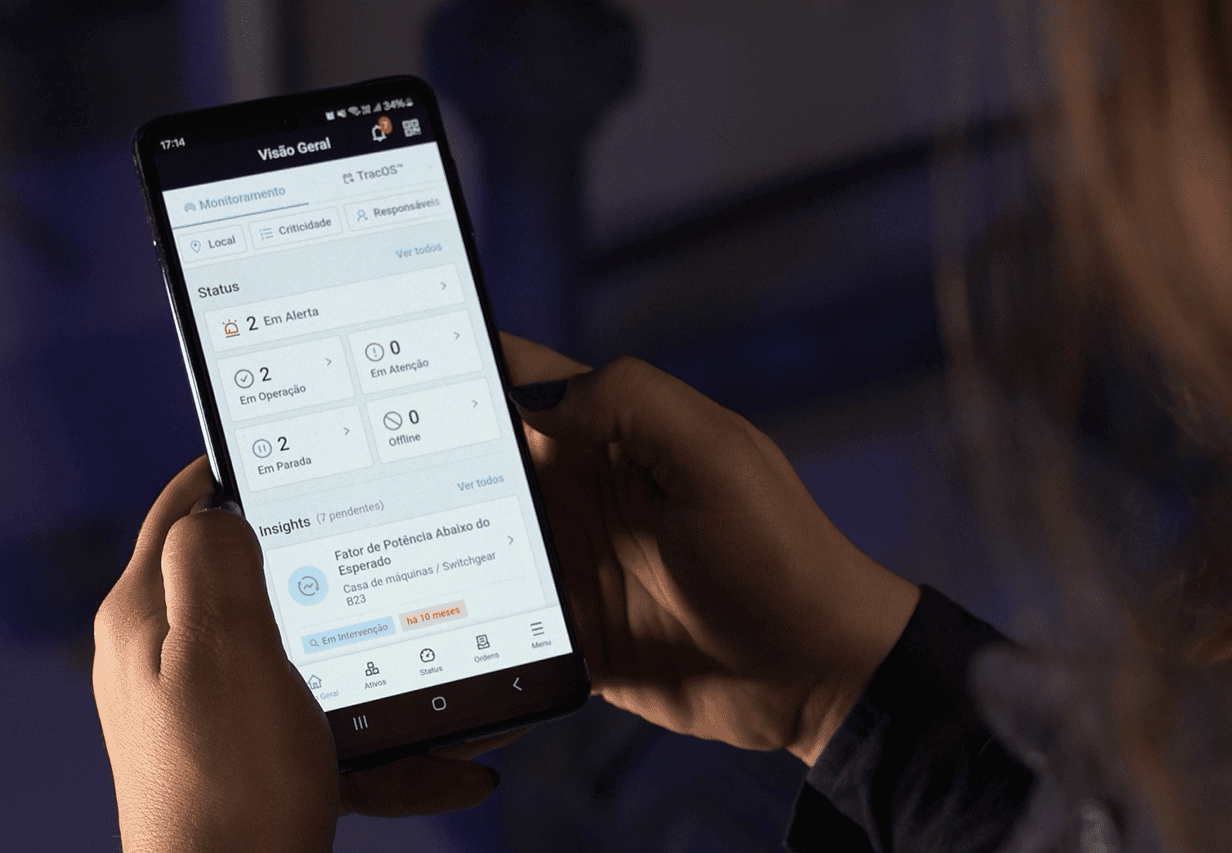

- Track - See work in real time—no extra clicks.

- Visualize - Turn raw history into actionable dashboards.

- Sustain - Win executive support with quick-win metrics.

- Digital Maturity Checklist – gauge your current readiness.

A Computerized Maintenance Management System is a single source of truth for assets, work, and parts. It replaces scattered files with structured data so your team can act, audit, and improve faster.

- Work Orders — turn ad-hoc calls into tracked tasks.

- Asset Registry — democratize “tribal knowledge” and end finger-pointing.

- Preventive Schedules — stop calendar creep and surprise downtime.

- Inventory — know what’s in stock before the line stops.

- Reporting — surface performance trends, not raw numbers.

FAQ

No. It’s designed for first-time evaluators and shows how to start from zero.

Both. Process explanations for managers, screenshots for technicians.

CMMS runs maintenance workflows; ERP handles finance and supply chain. They complement, not compete.

With cloud deployment and pre-built import tools, plants typically go live in under 14 days.

Absolutely. Technicians can create, execute and close work orders via the mobile app; all actions sync once connectivity returns, keeping maintenance traceable even when Wi-Fi drops.

Dashboards for MTTR, backlog, wrench time, availability and more are ready on day one, giving leadership board-ready numbers without manual reporting.

Explore all the materials we offer for free to help you grow professionally and elevate your industry expertise.

Ebook

Maintenance KPIs

We demystify all maintenance indicators to enhance your management.

4 min. read

Access Material

Ebook

Data-Driven Decisions

Transform the way you make decisions in the industry.

4 min. read

Access Material

Ebook

EAM Software: A Guide for Maintenance Managers

Discover how maintenance managers implement EAM software to enhance their reliability and avaliability metrics.

3 min. read

Access Material