How to Calculate Equipment Availability (Step by Step)

The standard formula is simple:

Availability = (Scheduled Time – Downtime) ÷ Scheduled Time

You’re measuring how much of your planned production time was free from stops, giving you a percentage that reflects how “ready” your equipment really is.

Example: If your scheduled production time was 1,000 hours, and the machine was down for 80 hours:

Availability = (1,000 – 80) ÷ 1,000 = 0.92 = 92%

What Is Equipment Availability?

It’s the percentage of time your equipment is ready to run when expected, not being stopped for maintenance, breakdowns, or delays. This is a key component of OEE and one of the clearest indicators of operational readiness.

Why Use an Equipment Availability Calculator?

Because availability isn’t about how long your equipment exists, but about how often it’s ready to deliver. This calculator gives you a clear percentage to track performance, compare across shifts or sites, and drive better scheduling and maintenance decisions.

What is a Good Availability Percentage?

World-class manufacturing typically aims for 90% or higher. If your availability drops below 85%, it may point to issues like poor maintenance scheduling, delayed responses, or excessive unplanned stops.

Availability is a metric of consistency and one of the easiest to track over time.

What Causes Availability to Drop?

- Unplanned downtime and reactive maintenance

- Slow response time to breakdowns

- Missing or unorganized spare parts

- Delayed changeovers or setup procedures

- Poor coordination between maintenance and production

When Should You Track Availability?

Track it daily or per shift on your most critical equipment. Use it in weekly operations reviews, monthly reliability reports, or anytime you want to compare performance across teams or production lines.

Availability is a leading indicator, it often drops before bigger problems show up.

How to Improve Equipment Availability?

- Strengthen your preventive maintenance routines

- Reduce emergency work through predictive alerts

- Standardize common repair procedures (SOPs)

- Keep critical spare parts stocked and accessible

- Monitor downtime types to eliminate recurring issues

- Analyze patterns across shifts or locations to spot systemic delays

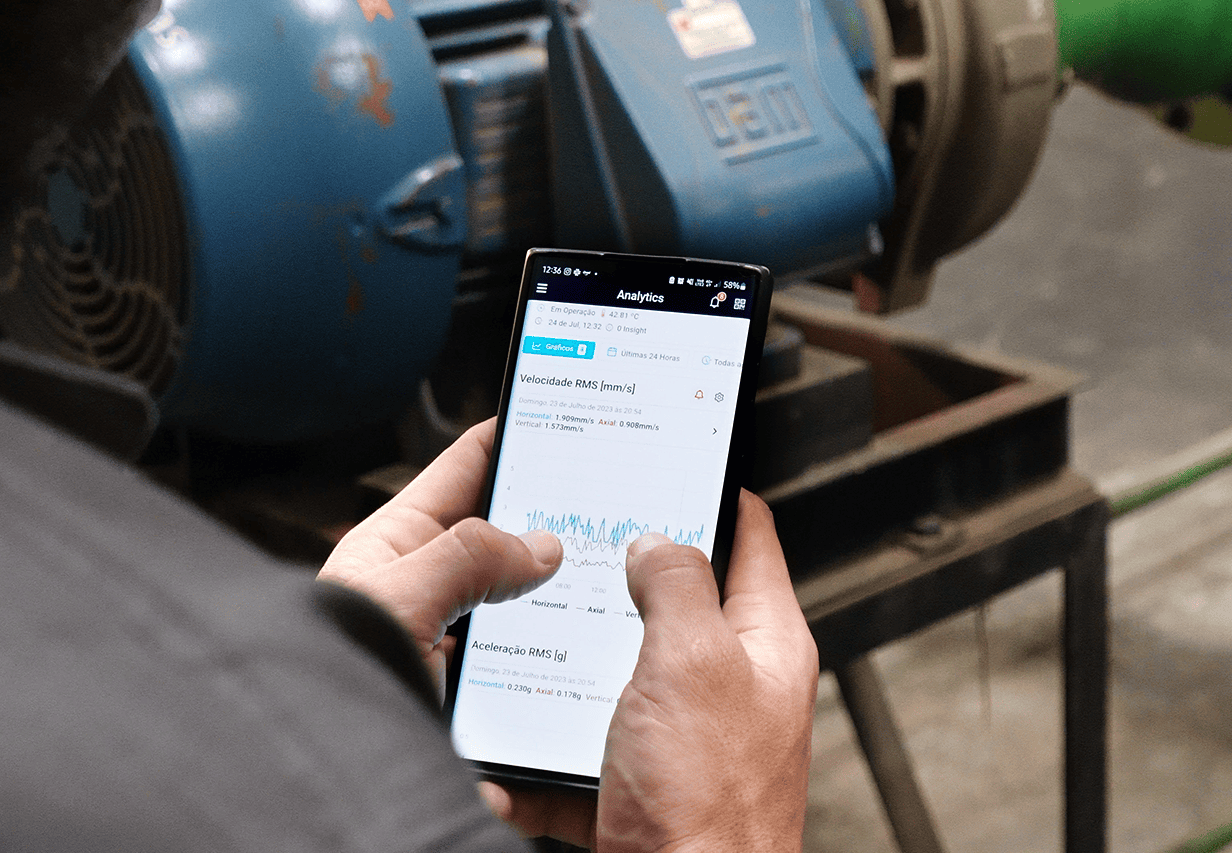

How Tractian Helps You Cut Downtime

Tractian’s condition monitoring alerts you the moment something starts to drift, before a breakdown happens. From vibration to temperature to historical trends, you’ll know exactly what’s putting availability at risk.

Pair that with real-time logging and downtime classification, and you get total visibility over why assets stop, and how to keep them running longer.

Request a Demo and see how Tractian’s condition-based monitoring solution works in your plant, spotting failures earlier, running more consistently, and improving availability with less guesswork.