How to Calculate Equipment Downtime (Step by Step)

There are multiple ways to calculate downtime depending on what you want to measure:

- Total Downtime (in hours/minutes): Add up all the time equipment was stopped during a given period, both planned and unplanned.

- Downtime as a Percentage Formula:

Downtime % = (Downtime ÷ Total Scheduled Time) × 100

- Downtime Cost Formula:

Cost = Downtime Duration × Hourly Asset Cost

Example: If a machine was stopped for 8 hours in a 100-hour week:

Downtime % = (8 ÷ 100) × 100 = 8%

What Is Equipment Downtime?

It’s the time any piece of equipment is not producing as planned, whether due to maintenance, failure, changeover, or delay. Downtime is normal, but when it goes untracked, it turns into hidden waste.

Why Use an Equipment Downtime Calculator?

Because even a 1% drop in uptime adds up quickly. This calculator gives maintenance and operations teams clarity on where performance is slipping and it helps identify underperforming assets, quantify the cost of lost time, and set realistic uptime goals.

It also supports root cause analysis by turning scattered time logs into structured insights you can act on.

What is a Good Downtime Benchmark?

It depends on your industry and how critical the asset is.

World-class operations, especially those following OEE standards, aim for less than 5% total downtime. For critical machines, the goal is often near-zero downtime to protect output. For non-critical equipment, trends matter more than isolated numbers. The objective isn’t perfection, but a steady, measurable improvement.

What Causes Equipment Downtime?

- Unplanned breakdowns

- Preventive maintenance windows

- Tooling/setup changes

- Waiting for parts or approvals

- Operator error

When Should You Track Downtime?

Always, but especially for:

- Bottleneck equipment

- High-value production lines

- Assets with frequent stops

How to Reduce Equipment Downtime?

- Use predictive maintenance to catch failures early

- Improve PM scheduling to avoid unnecessary stops

- Train operators to handle quick fixes

- Track stoppages by category to find the biggest time losses

- Make SOPs accessible and standardized for faster recovery

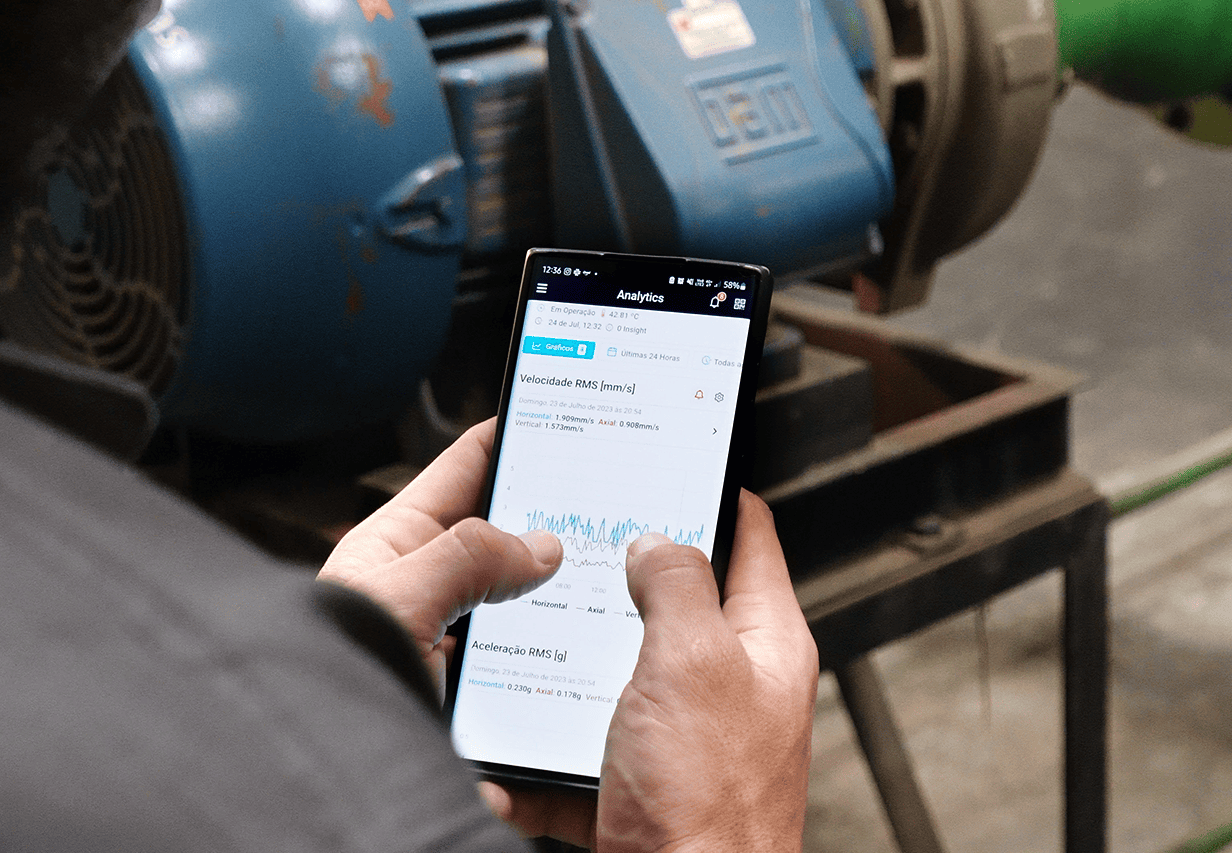

How Tractian Helps You Cut Downtime

Tractian’s condition-based monitoring detects anomalies in real time, warning your team before failures lead to equipment stops. Sensors monitor vibration, temperature, and other key indicators, allowing you to act early instead of after breakdowns happen.

With insights powered by machine learning, your team knows what’s happening, why it’s happening, and what to do next. Downtime stops being a surprise and starts becoming preventable.

See how Tractian’s condition-based monitoring solution works in your plant.