How to Calculate Failure Rate (Step by Step)

Failure Rate (λ) = Number of Failures ÷ Total Operating Time

This tells you how frequently a piece of equipment fails over a given time period. It's usually expressed as failures per hour.

1. Number of Failures

The total count of complete, unplanned failures during the time frame you're analyzing.

2. Total Operating Time

The cumulative number of hours the asset was running during that period.

Example:

If your equipment had 6 failures over 3,000 hours of operation:

λ = 6 ÷ 3,000 = 0.002 failures/hour

What is Failure Rate and Why Does It Matter?

Failure Rate helps you understand risk. The higher the rate, the more frequently breakdowns occur, which leads to more downtime, higher costs, and lower asset reliability.

What’s Considered a “Failure”?

Any unplanned breakdown that stops the equipment from operating. Failures include mechanical, electrical, or control issues that require repair to resume function. Minor stops or planned downtime are not included.

How to Use Failure Rate in Your Maintenance Strategy

Failure Rate is key to planning smarter.

- Identify high-risk assets

- Optimize maintenance intervals

- Support decisions around replacement vs repair

- Pair with MTBF for a full view of reliability

What Causes a High Failure Rate?

Lack of preventive maintenance, aging equipment, or poor root cause analysis. Recurring failures often indicate unresolved issues, but tracking λ helps you see what’s trending the wrong way.

What’s a “Good” Failure Rate?

It depends, but lower is always better. There’s no universal “perfect” failure rate. It varies by equipment type, operating conditions, and criticality.

That said:

- Lower λ = higher reliability

- Look for downward trends over time

- Use historical averages and industry benchmarks as your baseline

How to Improve Your Failure Rate and Lower It

The fewer failures, the better. Here's how to bring λ down:

- Perform preventive maintenance more consistently

- Use predictive maintenance tools to catch early warnings

- Replace or upgrade components before failure

- Train technicians to isolate and fix root causes

- Track asset history to avoid repeated issues

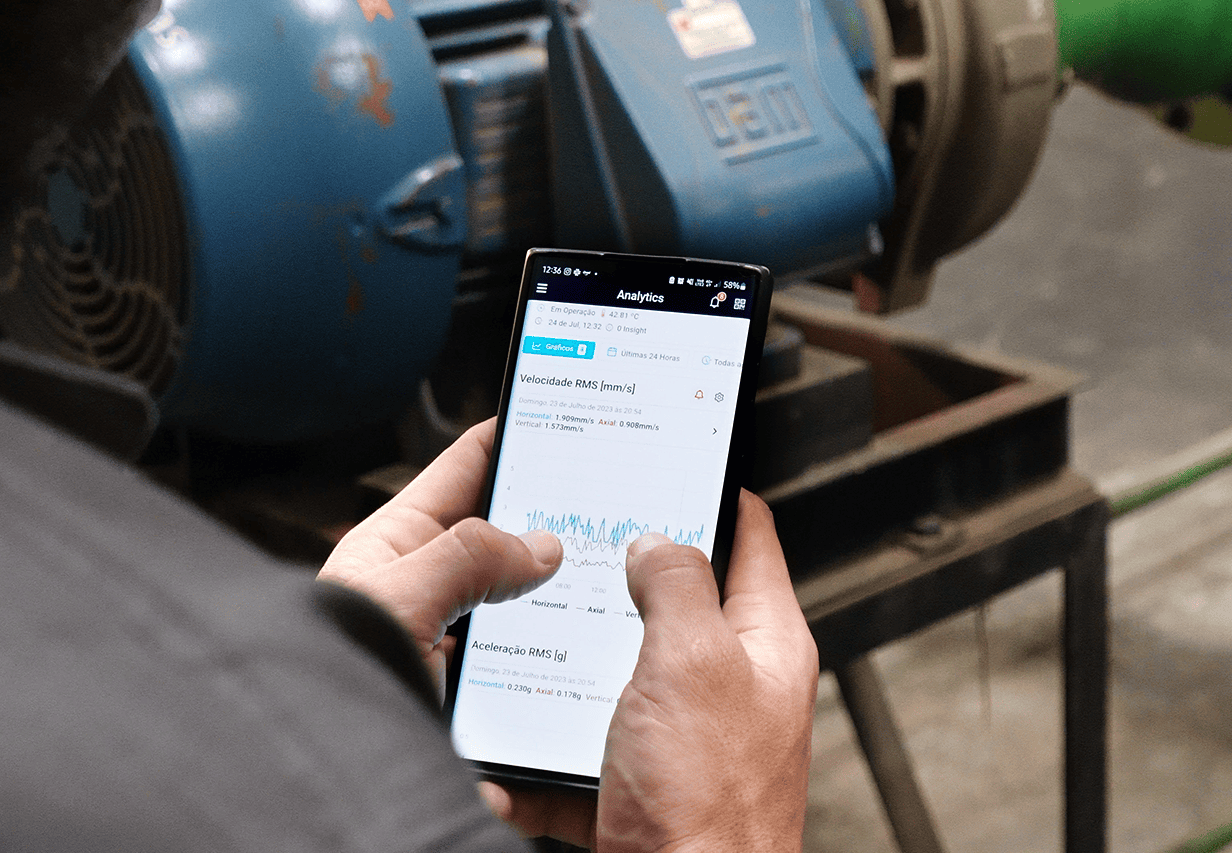

Why Automate Failure Rate Tracking with Tractian

Manual tracking hides patterns. Tractian reveals them. Our platform continuously monitors equipment health and logs failure events automatically, helping you reduce unplanned stops with AI-powered insights.

Failure Rate vs. MTBF - What’s the Difference?

They measure the same thing, but from opposite directions. Failure Rate (λ) tells you how frequently failures happen. MTBF (Mean Time Between Failures) tells you how long equipment runs before it breaks.

They're mathematically connected:

- Failure Rate (λ) = 1 ÷ MTBF

- MTBF = 1 ÷ λ

See How Tractian Helps You Reduce Failures

Stop reacting. Start predicting. Tractian CMMS helps you track failure rate, analyze performance, and take action before downtime costs you even more.