How to Calculate Mean Maintenance Cost (Step by Step)

MMC = Total Maintenance Cost ÷ Number of Maintenance Events

That means if you spent $120,000 on 80 maintenance tasks over a quarter, your MMC would be: MMC = 120,000 ÷ 80 = $1,500 per event

You can also calculate cost per failure, per asset, or by department, depending on the insight you want.

What Is Mean Maintenance Cost (MMC)?

Mean Maintenance Cost (MMC) is the average amount you spend on each maintenance event, whether it's a routine inspection, a repair, or a full corrective task. It’s more than just a budgeting metric as it works as a reflection of how efficiently your team is using time, labor, and parts to keep assets running.

Tracking MMC reveals whether your maintenance strategy is cost-effective or bloated with reactive work and hidden inefficiencies.

Why Does MMC Matter in Maintenance Strategy?

The average cost reveals your team's true efficiency. A rising MMC can point to reactive work, poor planning, or excessive time spent on low-value repairs. It helps teams question if they’re spending too much to keep certain assets running, and whether those assets are worth saving at all.

It does more than just tracking. At the end of the day, the MMC helps your team make smarter decisions with every dollar.

What’s a Good MMC Benchmark?

That depends on your asset type, failure rate, and maintenance model, but what really matters is the trend. If your MMC is rising steadily, or significantly higher on some machines than others, it’s a sign that cost control is slipping.

The goal isn’t to hit an ideal number, but to reduce waste, rebalance priorities, and stop investing blindly.

What Causes High MMC?

High MMC is often the result of reactive maintenance. When equipment fails unexpectedly, teams scramble and labor costs go up. That leads to lost time and repairs become more complex than necessary. It can also stem from poor diagnostics, lack of standard procedures, or insufficient spare parts management. In many cases, high MMC signals you're spending more to patch problems than to prevent them.

How to Improve MMC

Reducing MMC starts with doing fewer emergency repairs and doing more of the right work, at the right time.

To do so, strengthen your preventive maintenance schedule, adopt predictive tools where possible, and track cost per asset to identify the outliers. Standardizing repair procedures and ensuring parts are available before work begins also cut down time and cost per event.

Over time, improving MMC means building a process that values consistency over firefighting.

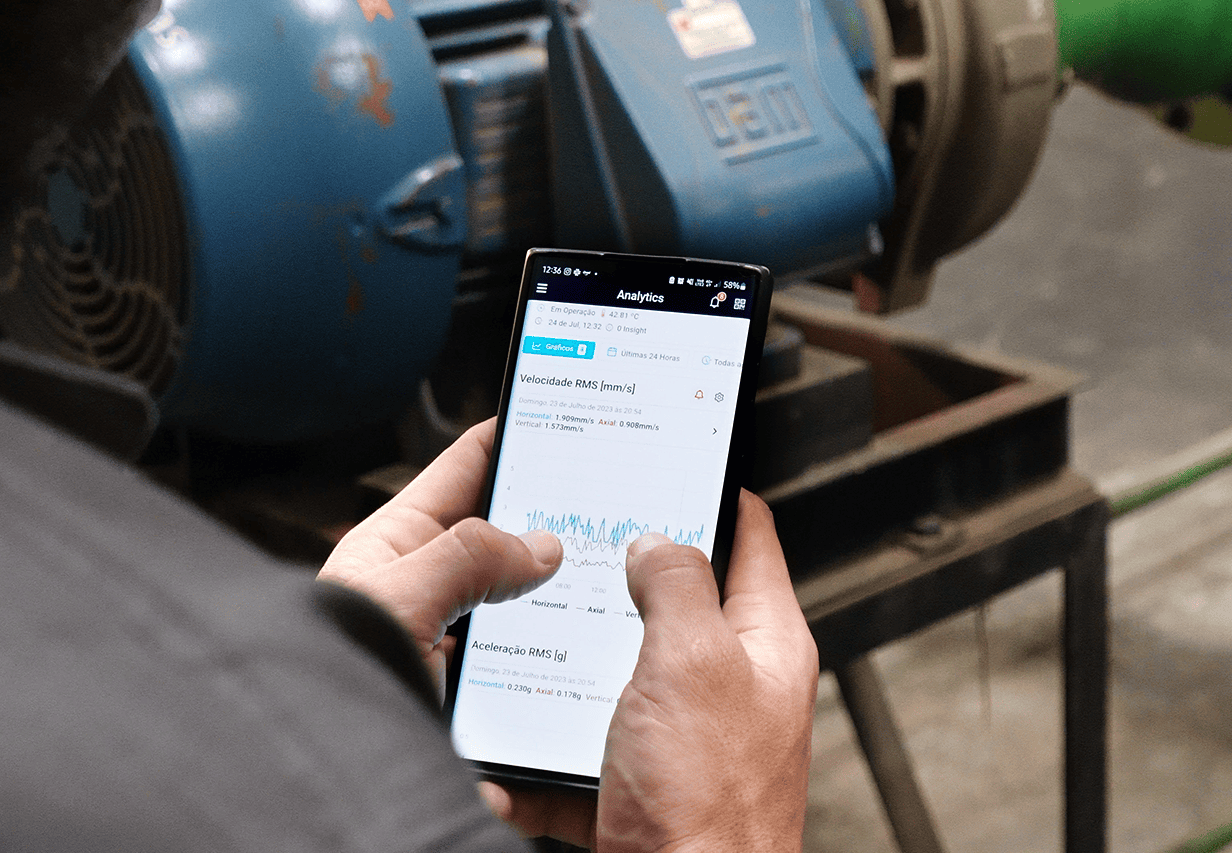

How Tractian Gives You Cost Control at the Asset Level

Tractian CMMS connects every work order, task, and part to the asset while also tracking cost automatically. You’ll know exactly how much you’re spending on each machine, which team is completing the work, and whether that spend is trending up or down..

No more chasing numbers across spreadsheets or departments. Just clear, asset-level cost intelligence, ready to act on.

Start a free trial today and see how Tractian CMMS can elevate your operation.