How to Calculate Preventive Maintenance Compliance (Step by Step)

PMC = (Number of Completed PMs on Time ÷ Number of Scheduled PMs) × 100

This formula gives you the percentage of scheduled preventive tasks that were completed as planned - on time and without delay.

Example: If 45 PMs were scheduled and 36 were completed on time:

PMC = (36 ÷ 45) × 100 = 80%

What Is Preventive Maintenance Compliance (PMC)?

PMC measures how reliably your team completes scheduled preventive maintenance activities. It reflects how well your team follows through on the plan and how disciplined your processes really are.

Why Use a PMC Calculator?

Because delays in preventive maintenance lead directly to failures.

This calculator helps you measure how reliably your team is executing the plan, not just scheduling tasks, but actually completing them on time. A high PMC means your assets are being cared for proactively. A low score is a red flag that downtime and avoidable costs are around the corner.

What is a Good PMC Percentage?

World-class maintenance teams aim for 90% or higher.

Below 80% often indicates issues with planning, parts availability, labor allocation, or prioritization. The closer you are to 100%, the more stable and reliable your maintenance program becomes.

What Causes Low PMC?

- Missed work due to staffing issues or reactive repairs

- Delayed PMs from poor scheduling or conflicting priorities

- Lack of available parts or unclear instructions

- Overloaded calendars with too many low-priority tasks

How to Improve Preventive Maintenance Compliance

- Automate PM scheduling to ensure nothing is missed

- Allocate labor based on criticality, not just workload

- Pre-stock parts and standardize instructions

- Use digital work orders with mobile access to reduce delays

- Review PMC trends by asset or technician to find weak spots

How Tractian Helps You Cut Downtime

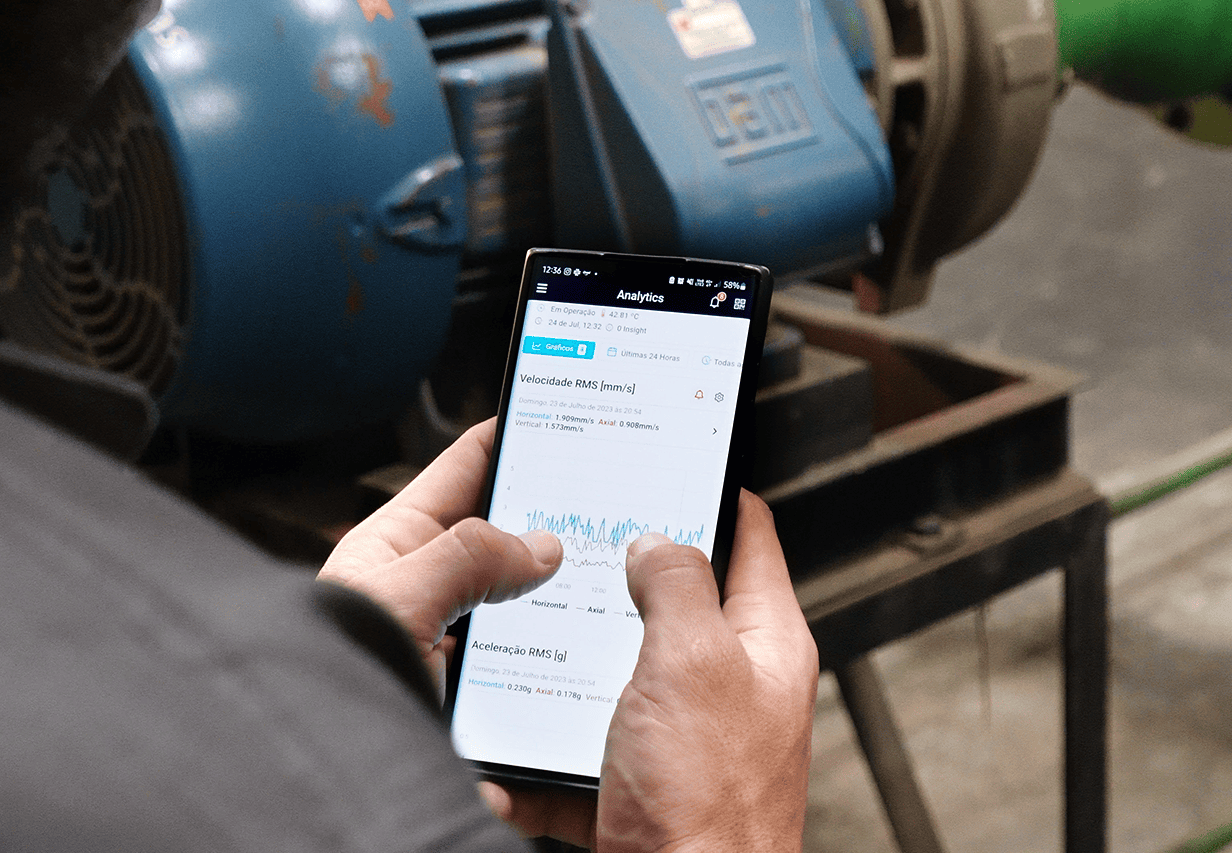

Tractian CMMS tracks PMC automatically, flagging overdue activities, highlighting risk by asset, and giving managers full visibility into what’s slipping and why.

You know which technician missed a deadline, which asset went unprotected, and where execution is breaking down. No more spreadsheets, chasing updates, or guessing if the plan was followed. Instead, you’ll see it, measure it, and fix it.

All within one single platform.

Start a free trial today and see how Tractian CMMS can change your operation.