How to Calculate PMP (Step by Step)

PMP = (Planned Maintenance Hours ÷ Total Maintenance Hours) × 100

This formula tells you what percentage of your maintenance activities were scheduled, rather than reactive.

- Planned Maintenance Hours: All time spent on scheduled tasks like inspections, preventive work, or service routines.

- Total Maintenance Hours: The sum of all maintenance time, both planned and unplanned, for the period.

Example - If you spent 320 hours on total maintenance, and 240 of those were planned:

PMP = (240 ÷ 320) × 100 = 75%

What is PMP and Why Does It Matter?

Planned Maintenance Percentage shows how proactive your maintenance really is. A higher PMP means fewer surprises, lower emergency costs, and more control over your operation.

What Does a Low PMP Indicate?

You’re spending more time reacting than preventing. A low PMP usually points to missing inspections, backlog of preventive tasks, or too many unexpected breakdowns.

What’s a Good PMP Benchmark?

The industry benchmark is 85% or higher. That means 85% of your maintenance hours should be scheduled. Anything below 60% is considered reactive-heavy and risky.

How to Improve Your PMP

Move away from firefighting-here’s how:

- Prioritize preventive tasks in your weekly maintenance schedule

- Use digital tools to automate recurring PMs

- Review and resolve root causes to avoid repeat breakdowns

- Balance team capacity between reactive and planned work

- Track compliance (PMC) to ensure PMs are actually completed

Why PMP Isn’t Just a Metric - It’s a Maintenance Strategy

Raising your PMP shifts your team from reactive mode to high-performance reliability. It reduces emergency costs, minimizes downtime, and extends equipment life. It’s not just a number, it’s a mindset.

PMP vs PMC: What’s the Difference?

PMP tracks how much of your total maintenance is planned. PMC tracks how much of your planned work actually gets done. Together, they show how proactive, and disciplined, your maintenance strategy really is.

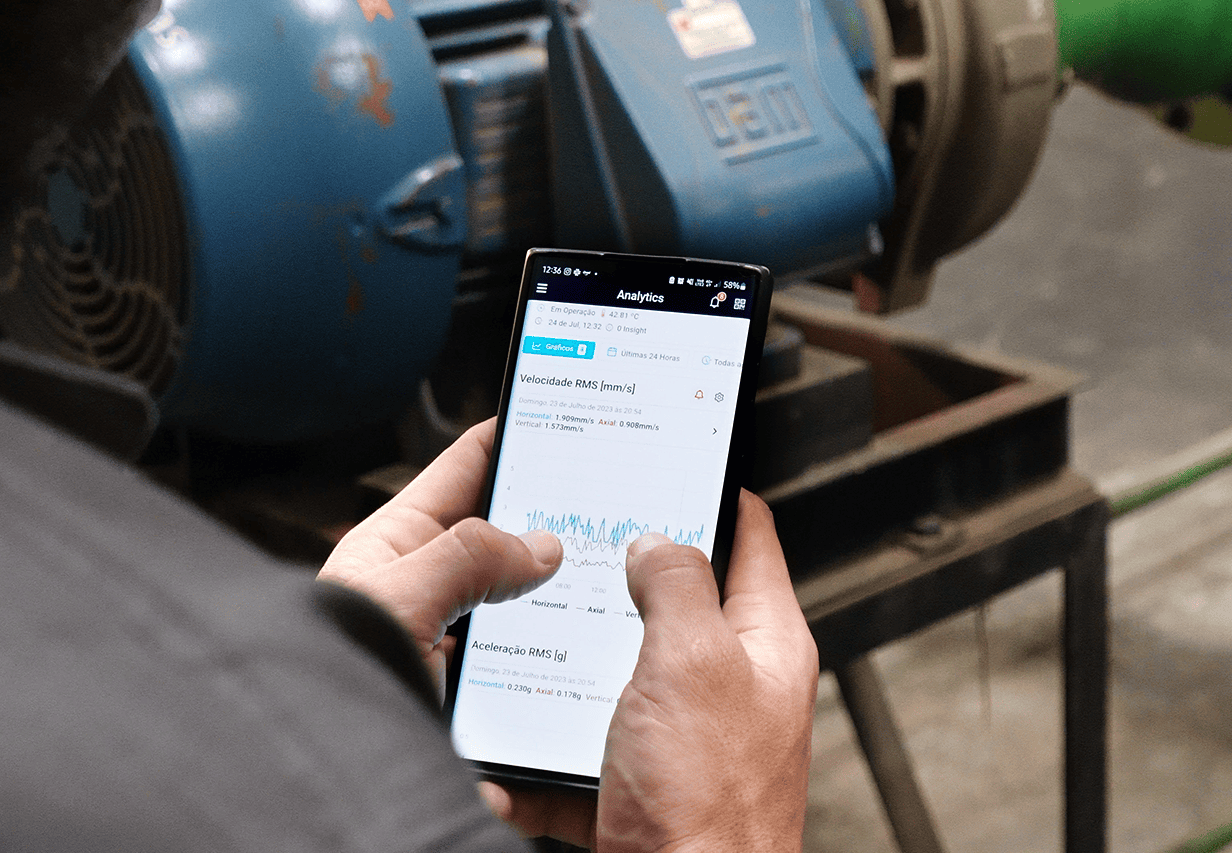

Why Automate PMP Tracking with Tractian

Stop guessing how much is planned and let Tractian track it for you. Our CMMS platform schedules, logs, and analyzes all maintenance activity, automatically calculating PMP, PMC, and more. It shows where your time is going and how to fix what’s not working.

See How Tractian Helps You Boost PMP

Turn maintenance chaos into a predictable, reliable operation. With real-time tracking and predictive insights, Tractian's condition monitoring solution helps you stay ahead of failures and increase your planned maintenance share, without increasing workload.