How to Calculate Unplanned Downtime (Step by Step)

There’s no single formula since it depends on what you want to track:

Total Unplanned Downtime (in time): Add up all the minutes or hours lost due to unexpected equipment failures during a given period.

Cost of Unplanned Downtime: This one does have a formula, which is:

Downtime Cost = Downtime Duration × Hourly Cost of Asset (or Line)

Example:

If a machine fails for 3 hours and costs $1,500/hour to operate:

Downtime Cost = 3 × $1,500 = $4,500

What Is Unplanned Downtime?

Unplanned downtime is any unscheduled stop in operations due to failure, malfunction, or delay. Unlike planned maintenance, this type of stoppage is disruptive, costly, and usually avoidable, making it one of the biggest hidden drains in manufacturing and facilities.

Why Use an Unplanned Downtime Calculator?

Because you can’t reduce what you don’t measure. This calculator helps you identify how much time (or money) is lost to surprise failures and where improvements in maintenance, planning, or training can recover it.

What’s a Normal Amount of Unplanned Downtime?

There’s no universal number, but less is always better.

Industry benchmarks suggest world-class operations keep unplanned downtime below 5% of total available time.If you're above 10%, it's likely impacting your throughput, labor costs, and delivery reliability.

What Causes Unplanned Downtime?

- Equipment failure or breakdowns

- Lack of preventive maintenance

- Delayed response or slow diagnostics

- Missing spare parts or tools

- No clear SOP for critical repairs

How to Reduce Unplanned Downtime

You don’t need more people, just better visibility and preparation.

Start with:

- Real-time asset monitoring

- Predictive alerts for early warning signs

- Strong PM compliance

- Trained teams and documented repair processes

- Pre-stocked parts for high-failure components

How Tractian Helps You Eliminate Unplanned Downtime

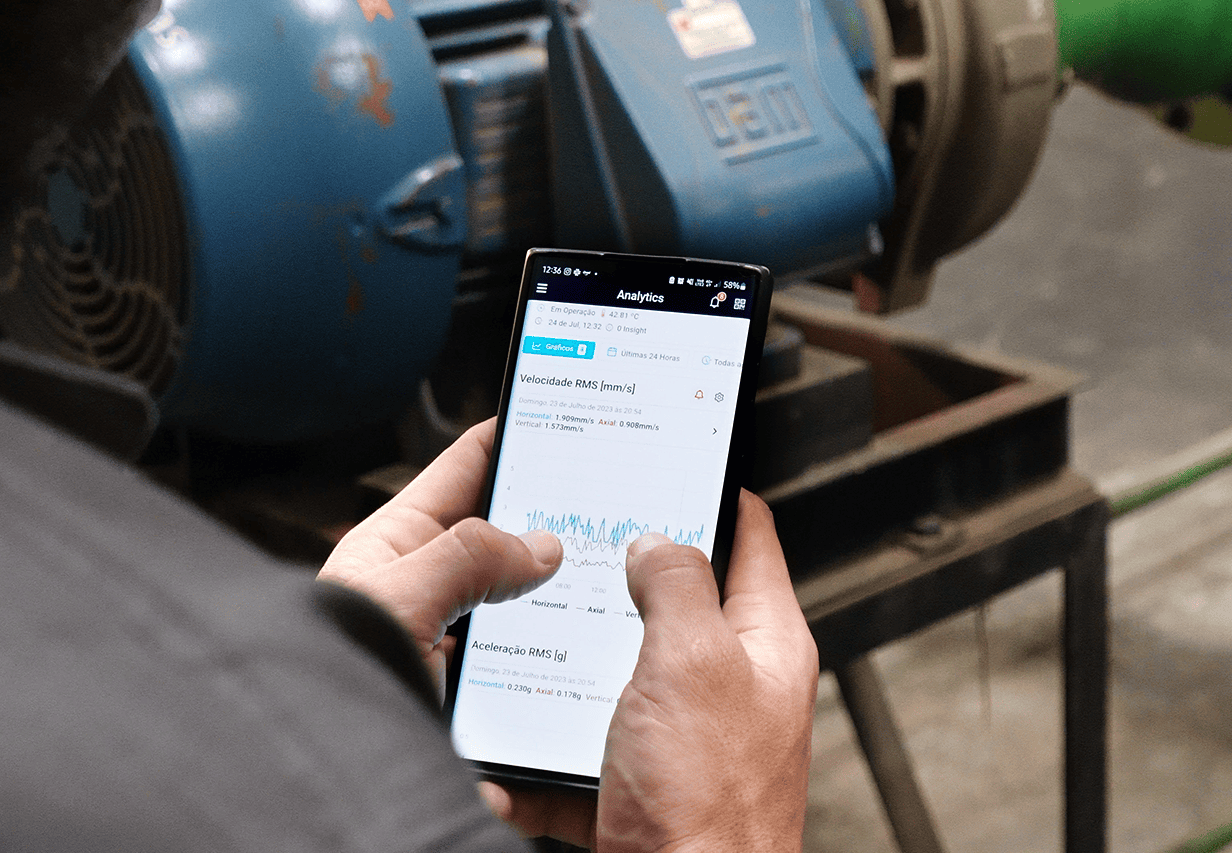

Tractian combines real-time condition monitoring with a smart CMMS, so you know exactly when a failure is coming, how to prevent it, and how fast to respond.

From automated alerts to root cause tracking, our platform helps maintenance teams stay ahead of failures, not just react to them. Start a free trial today.