- Free Resources

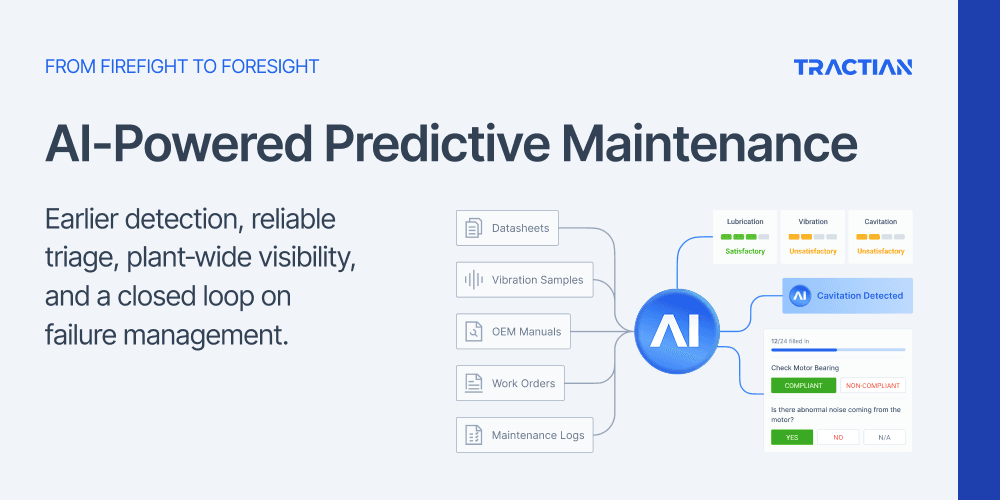

AI-Powered Predictive Maintenance

Your material is almost ready!

Just complete a quick registration, and your material will be available.

AI-Powered Predictive Maintenance

Just complete a quick registration, and your material will be available.

Unplanned downtime costs the world’s top manufacturers USD 1.4 trillion every year — around 11% of total revenue.

Traditional predictive maintenance tools detect symptoms; AI detects root causes.

With AI, your maintenance program gains:

→ Early Detection: Always-on monitoring surfaces issues before escalation

→ Reliable Insights: Evidence-based alerts connected to actionable work orders

→ Complete Visibility: One platform that unites vibration, oil, and thermal data

→ Validated Decisions: Transparent AI models that show why each alert fires

1. How AI Changes the Routine

→ Move from monthly checks to continuous monitoring with confidence scoring and fault-specific insights.

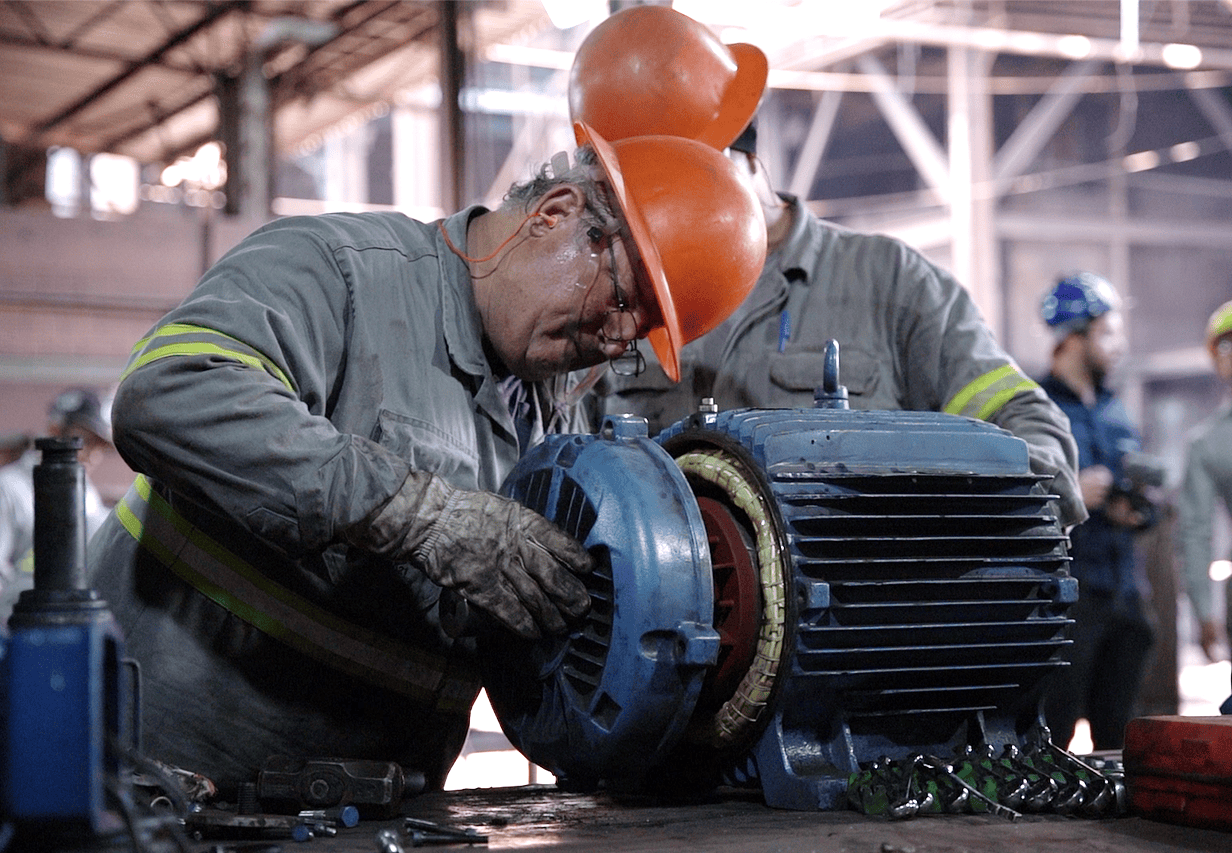

2. Smarter Intervention, Lower Cost

→ Diagnose before escalation. Time repairs to condition and reduce labor and parts spend.

3. Alert Precision, Not Alert Fatigue

→ Prioritize the right work with AI-ranked alerts by severity and asset criticality.

4. Unified Intelligence for Maintenance

→ Centralize vibration, oil, thermography, and ultrasound into one asset timeline for faster, evidence-based action.

Ingredion (Food & Beverage)

– USD 1.6M in production savings

– 168 hours of downtime avoided

CP Kelco (Chemicals)

– USD 446K in total savings

– 84 hours of avoided downtime

Both achieved measurable ROI by turning insights into planned work orders — not emergency calls.

Unplanned downtime costs the world’s top manufacturers USD 1.4 trillion every year — around 11% of total revenue.

Traditional predictive maintenance tools detect symptoms; AI detects root causes.

With AI, your maintenance program gains:

→ Early Detection: Always-on monitoring surfaces issues before escalation

→ Reliable Insights: Evidence-based alerts connected to actionable work orders

→ Complete Visibility: One platform that unites vibration, oil, and thermal data

→ Validated Decisions: Transparent AI models that show why each alert fires

1. How AI Changes the Routine

→ Move from monthly checks to continuous monitoring with confidence scoring and fault-specific insights.

2. Smarter Intervention, Lower Cost

→ Diagnose before escalation. Time repairs to condition and reduce labor and parts spend.

3. Alert Precision, Not Alert Fatigue

→ Prioritize the right work with AI-ranked alerts by severity and asset criticality.

4. Unified Intelligence for Maintenance

→ Centralize vibration, oil, thermography, and ultrasound into one asset timeline for faster, evidence-based action.

Ingredion (Food & Beverage)

– USD 1.6M in production savings

– 168 hours of downtime avoided

CP Kelco (Chemicals)

– USD 446K in total savings

– 84 hours of avoided downtime

Both achieved measurable ROI by turning insights into planned work orders — not emergency calls.

Learn how modern CMMS systems connect work orders, asset history, and real-time KPIs to your predictive strategy — transforming AI insights into execution.

Download Extra Guide NowFAQ

AI-powered PdM blends vibration, temperature, and operational data to detect failures earlier and explain why they happen. Each alert is transparent, evidence-based, and linked to a recommended action.

Traditional PdM tools flag anomalies; AI systems interpret patterns, triage alerts, and connect them directly to work orders — creating a closed loop from insight to resolution.

No. Tractian installs and streams live data within hours.

Plants typically detect validated early-stage faults in the first week, and can deploy at scale within 90 days through a risk-free pilot program.

Yes. Tractian integrates natively with SAP, Oracle, and other ERPs, synchronizing maintenance actions and cost trails automatically.

AI-Powered Predictive Maintenance applies to continuous and discrete manufacturing environments. It also empowers logistics and off-highway operations.

Explore all the materials we offer for free to help you grow professionally and elevate your industry expertise.

Ebook

How AI-Powered CMMS Boosts Maintenance Efficiency

A practical checklist of what a high-impact CMMS must deliver. See how a CMMS ends paper chaos, delivers real-time KPIs and audit-ready history.

10 min. read

Access Material

Spreadsheet

Reliability-Centered Maintenance

Manage maintenance indicators and asset availability and reliability data in a single, results-focused spreadsheet.

Access Material

Ebook

Predictive Maintenance

It is time to move beyond emergency corrections and learn the benefits of predictive maintenance.

3 min. read

Access Material