Smart Trac™

Industrial Vibration Sensor

Accurately monitor the condition of your industrial equipment in real time. Avoid unexpected failures, reduce costs and increase operational efficiency.

3-minute Setup

Our vibration sensor is patented, making it unique - and the most advanced - in the predictive maintenance market. Smart Trac has 4G/LTE connectivity and automatically sends out real-time alerts about any change in vibration that could indicate a potential problem.

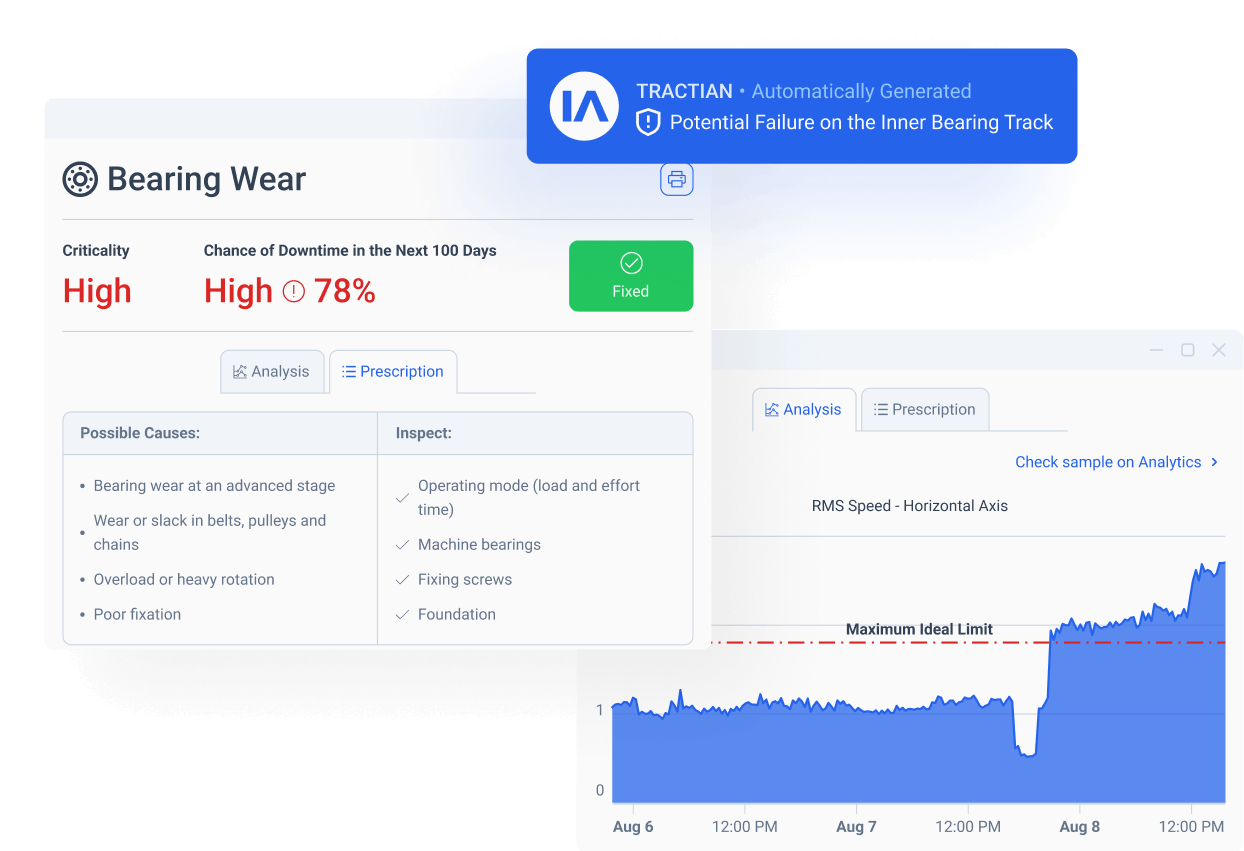

70+ Faults Anticipated and Diagnosed

•Lubrication faults

•Bearing Wear

•Beats

•Shovel Passage

•Vane passage

•Cavitations

•Turbulence

•Pump Recirculation

•Damaged rotor bars

•Loose rotor bars

•Gear wear

•Eccentricity of gears

•Loose stator windings

•Misalignment

•Operational Problems

•Pipe deformation

•Resonance

•Rotational Mechanical Clearance

•Structural Mechanical Clearance

•Rotor Eccentricity

•Rotor Gearing

•Friction or shear

•Eccentricity of the shaft

•Bearing erosion due to current leakage

•Stator Eccentricity

•Belt Wear

•Pulley wear

•Excessive vibration

Avoid unexpected failures, reduce maintenance costs and increase operational efficiency.

Smart Trac's Technology Doesn't Stop at the Alert of Failures

Fault Detected

Fault Alert

Diagnosis and Prescription

Fault Confirmed by the Maintainer

Continuous Learning

With each fault identified and insight checked, our technology absorbs the data and enhances its knowledge about the machine for the next detections.

Continuous Learning

Prediction with Unique and Exclusive TRACTIAN Technology

Objective data without interference from external factors

The constant collection of information disregards temperature oscillations from one season to another, eliminating errors and allowing accurate fault detection, considering only the temperature of the analyzed asset.

Accurate health report within 5 days

The state of health of the asset through vibration, precisely, up to 5 days after installation, enhancing the reading of the machine's behavior and its ideal functioning in the industry, identifying failures from the first days of installation.

Who Uses Smart Trac

Companies that have critical industrial equipment that needs constant monitoring

Professionals/Industries seeking to increase operational efficiency, reduce maintenance costs, and avoid unscheduled downtime

Managers, Supervisors, Directors, Operators, Technicians, and Planners who need to work with real-time data

See how much you can save with Smart Trac™

Automatically detect faults in your assets and eliminate downtime production stoppages with TRACTIAN sensors

Downtime Estimated Savings

↓ 43%

↓ 43%

-

Finance saving ≈

-

Time saving ≈

See more savings that Smart Trac™ can offer you

↓ 80%

Overtime costs reduction

↓ 30%

Preventive costs reduction

↓ 20%

Process loss costs reduction

Compatible with 30+ asset categories

An accurate, reliable, rugged, and easy-to-install vibration sensor, designed for any application on both light and heavy machinery.

An accurate, reliable, rugged, and easy-to-install vibration sensor, designed for any application on both light and heavy machinery.

Centrifugal Motor Pump

Peripheral Motor Pump

Gearmotor

Electric Motor

Overhead Crane

Hydraulic Press

Reducer

Sealing Machine

Turbine

Fan

HVAC

CNC

CNG Compressor

Screw Compressor

Piston Compressor

Discover Why People Consistently Choose TRACTIAN

FEATURE

Exclusive Patented Fault Diagnosis Capability

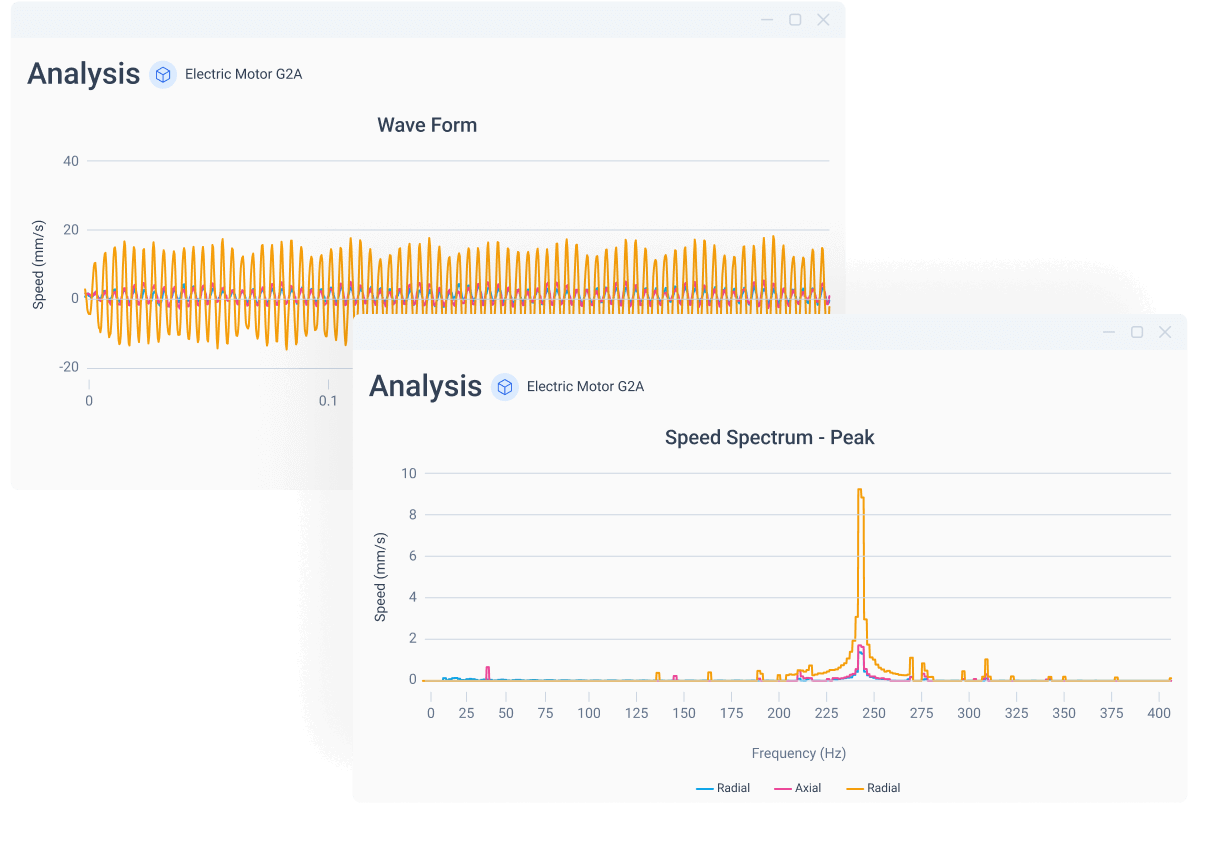

Full Spectrum Vibration Analysis

Cloud-based Software

Historical Trend Analysis

Condition-based Maintenance

Work Order Automation and Maintenance Scheduling

Mechanical with Electrical Monitoring Combined

Analysis of Machine Performance Compared to Your Competitors

Mobile network connectivity included with no industrial WiFi required

TRACTIAN

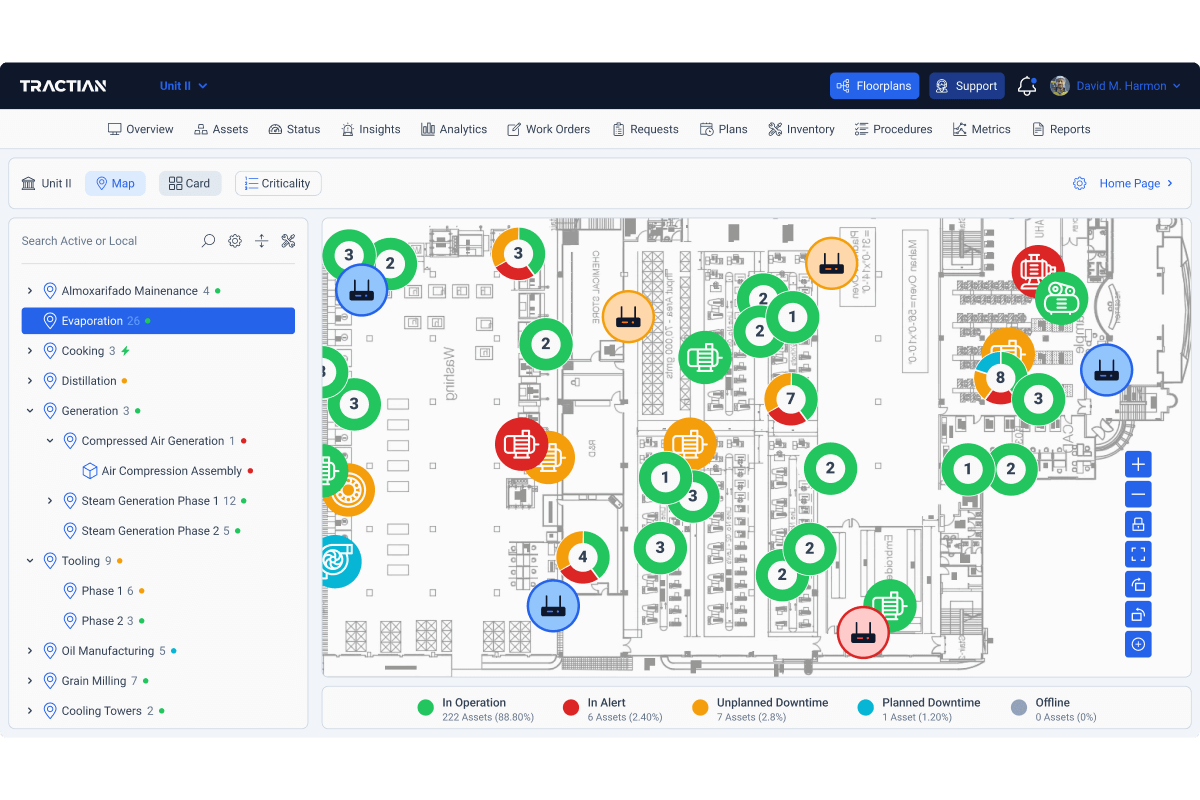

Complete and Simplified Predictive Maintenance

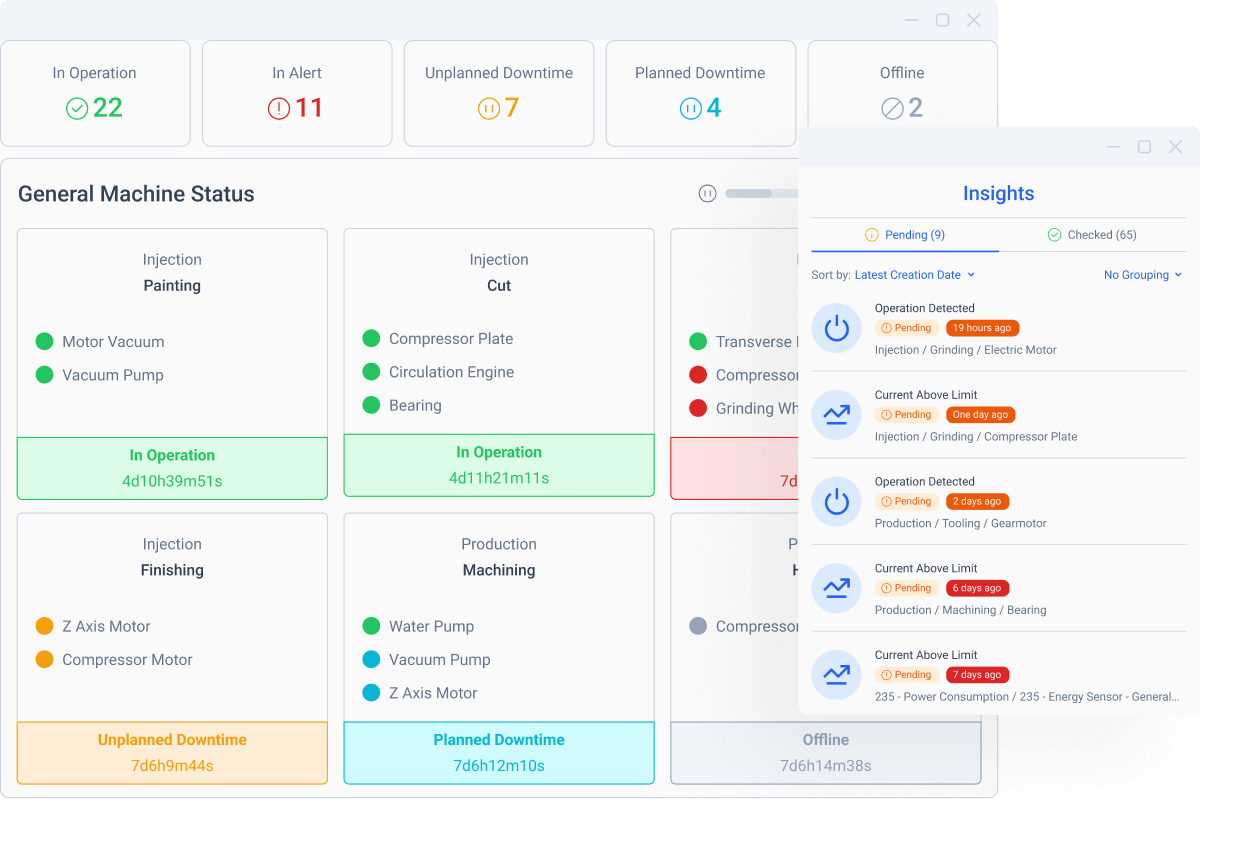

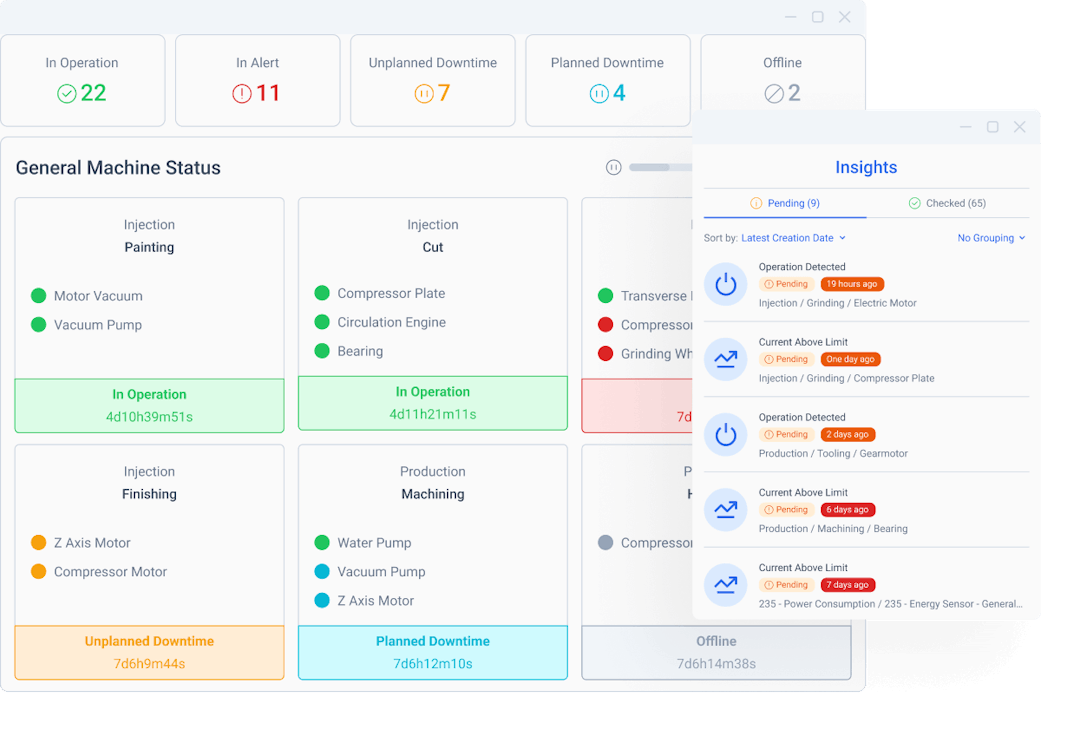

• Assets Overview

Follow your machine's health anytime

• Automatic Status Detection per Asset

• Total time per State calculated in real time

• Latest Insights, Insight Status and automatic alarm criticality level

• Prescriptive Insights

• Spectral Analysis Tool

• Virtual Blueprint for Supervisors

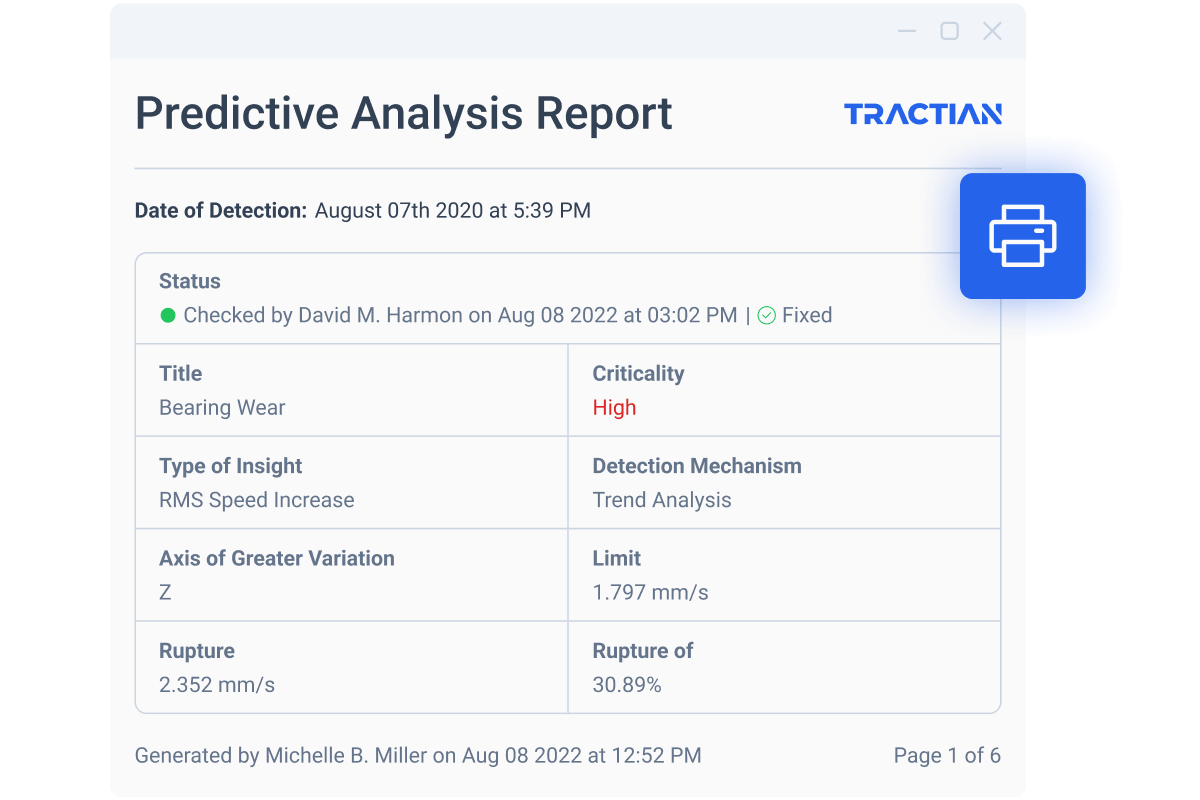

• Predictive Analysis Report

With the best predictive

solution you can:

Monitor and analyze the vibration and temperature of your equipment in real time

Identify potential failures before they occur

Receive immediate alerts in case of deviations or anomalies

Schedule preventive maintenance based on reliable data

Increase the life of your equipment and reduce maintenance costs

Monitor and analyze the vibration and temperature of your equipment in real time

Identify potential failures before they occur

Receive immediate alerts in case of deviations or anomalies

Schedule preventive maintenance based on reliable data

Increase the life of your equipment and reduce maintenance costs

Smart Trac Installation

After selecting the best monitoring points, the TRACTIAN team sends the sensors

Depending on your plant, the sensor can be attached to the asset by adhesive or screws.

Now you’ll have your asset health report in hand, and in less than 24 hours, the first possible failure identified. In a few days, the artificial intelligence will have learned the behavior of the machine and will start detecting failures in advance.

An unstoppable sensor, just like your assets.

IP69K resistance against steam and high-pressure water jets

Lined with the thermal insulation Makrolon 2407

Temperature sensor as close as possible to asset without being invasive

Fixing by adhesive or screws

Up to three years of battery life

Connection via 4G included

Smart Trac Technical Specifications

Measurements

Frequency

From 1Hz to 32000 Hz

Acceleration

Up to 16g

Velocity

Up to 100 mm/sRMS

Temperature measurement

From -40°F to 200°F

FFT Resolution

4096 lines(per axis)

Typical configuration

Collects every 5 minutes

Sample duration

1kHz(8s), 2kHz(4s), 4kHz(2s), 8kHz(1s), 16kHz(0,5s), 32kHz(0,25s)

Wireless Communication

Frequency

2.4GHz ISM

Protocol

IEEE 802.11b/g/n

Bands Communication

14 frequency channels, dynamically chosen

Range

Up to 50 meters radius between sensor and receiver with obstacles/barriers

Physical Characteristics

Dimensions

40(W)x78,5(H)x40(D)mm

Weight

155g(sensor) and 20g(base)

External Material Building

Makrolon 2407

Fixation

By adhesive or screws

Humidity

Suitable for installation in high humidity areas

Electronic Encapsulation

100% Resin encapsulation

Cybersecurity

Sensor to receiver communication

Encrypted AES(128 bits)

Homologation

FCC

Environmental Characteristics

IP Rating

IP69K

Operation Temperature

From -40°F to 200°F

Hazardous Area Rating

Zone 1 and 2 (gas), Zone 0, 1 and 2 (dust)

Power Source

Battery

Non-replaceable lithium battery

Tipic LifeTime

Up to 3years(configuration dependent)

Adversely Factors Affecting Battery Life

Temperature,Transmission range and sample configuration