Falhas mecânicas: Quais as melhores práticas para prevenção

As falhas mecânicas em máquinas e equipamentos geralmente estão relacionadas a problemas durante a elaboração do projeto, na sua fabricação ou na operação/manutenção. Em todos os casos isso acontece pela negligência em seguir procedimentos existentes para se evitar a falha prematura do ativo. Em muitos dos casos as falhas mecânicas podem acontecer por falta de métodos e ferramentas adequadas. Portanto é necessário em todas essas etapas, desde o projeto à sua operação, inserir métodos de prevenç

Keep readingLatest Articles

Artificial Intelligence Assisted Maintenance, The Evolution of Reliability

Much is discussed about different types of maintenance and how they’ve evolved over time. But one thing is crystal clear: technology plays a pivotal role in giving rise to new categories of maintenance. And the freshest example of this phenomenon is Artificial Intelligence Assisted Maintenance. AI has been a hot topic in industrial and manufacturing circles over the past few years. What used to feel remote from the everyday lives of maintenance experts and shop floor professionals has no

Tractian Inc

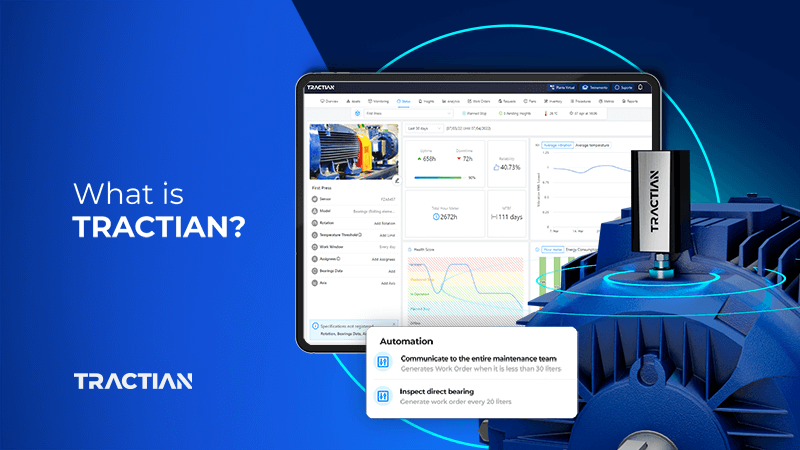

How TRACTIAN Helps Your Maintenance Management

TRACTIAN exists to facilitate and optimize the routine of the professionals who work on the front line of industries, the maintenance managers. Our goal is simple and clear, but understanding how we put it into practice may seem a little more complicated, since our products differ from everything else in the maintenance market today. That is why, today, we bring you a complete manual of all the TRACTIAN solutions so you can understand once and for all who we are, what we do, and how our predi

Alex Vedan

How can QR Codes optimize Maintenance Management?

Technology has played its part in maintenance since the first industrial revolution, but it has advanced considerably since then. In the same way, maintenance and management tools have been updated to keep up with the industry’s evolution and growth, besides increasing equipment reliability. Consequently, the need for maintenance resources, asset management and reliability indicators has grown in production lines. Unlock Efficient Maintenance Nowadays, we have advanced technolo

Tractian Inc

TRACTIAN Video Library

Discover our YouTube ChannelComprehensive free materials for your maintenance and reliability

Get free access to materials for increased productivity and an optimized maintenance routine.